Composite negative electrode pole piece and preparation method therefor, and lithium ion battery for mobile base station

A technology of negative pole piece and negative pole is applied in the field of composite negative pole piece and preparation method thereof, and the field of lithium ion battery for mobile base station, which can solve the problem of poor cycle performance of new negative pole material, low energy density of lithium ion battery, and inability to meet high rate charging. Discharge and other problems to achieve the effect of reducing thermal runaway, preventing excessive local temperature, and high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

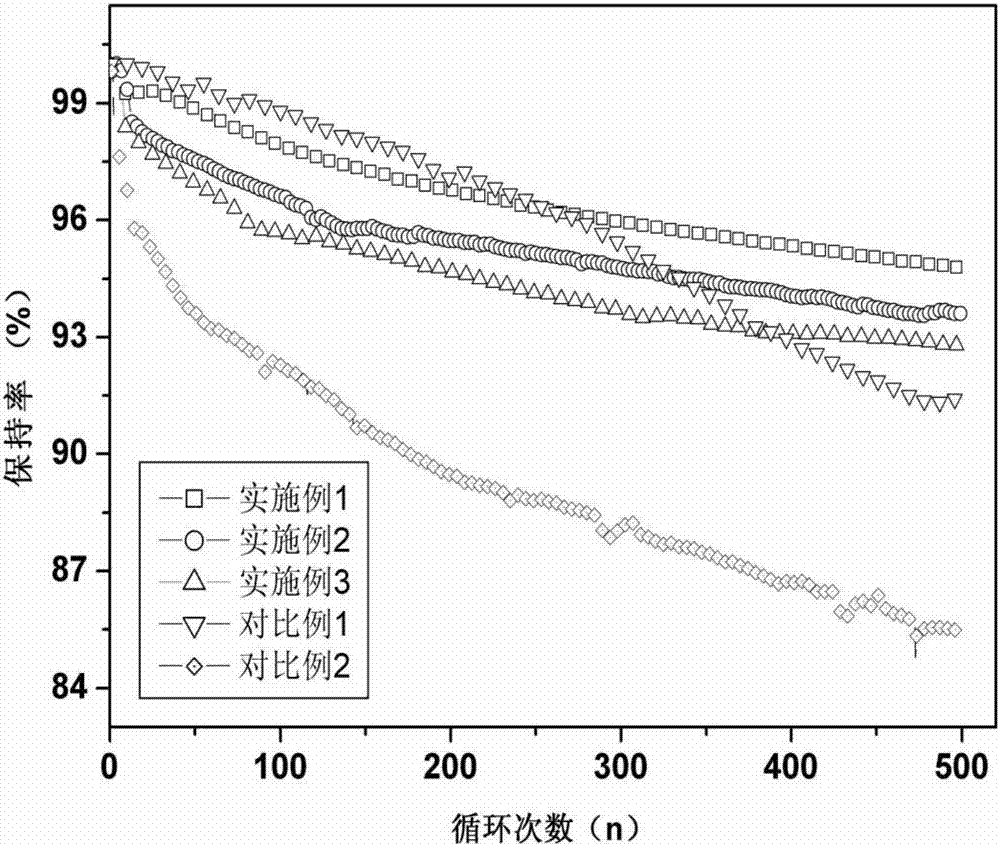

Examples

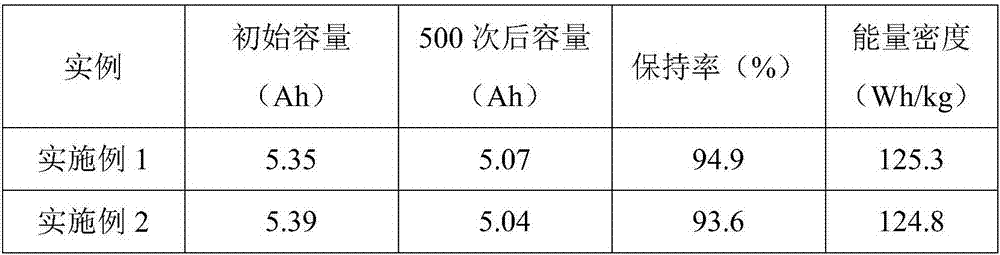

Embodiment 1

[0053] The composite negative electrode sheet in this embodiment includes a conductive heat dissipation layer, a negative electrode active material layer and a red phosphorus layer sequentially stacked on both sides of the negative electrode current collector from the inside to the outside.

[0054] The negative electrode current collector is a 10 μm copper foil. The thickness of the conductive heat dissipation layer is 3 μm. The negative electrode active material layer was 120 μm. The thickness of the red phosphorus layer is 2 μm.

[0055]The conductive heat dissipation layer is composed of the following materials uniformly mixed and bonded together: 8g binder polyvinylidene fluoride, 8g conductive agent carbon nanotubes, 85g nitrogen phosphorus compound ammonium polyphosphate.

[0056] The negative electrode active material layer is composed of the following materials uniformly mixed and bound together: 94g of artificial graphite, 2g of carbon nanotubes, and 3g of LA132 bi...

Embodiment 2

[0066] The composite negative electrode sheet in this embodiment includes a conductive heat dissipation layer, a negative electrode active material layer and a red phosphorus layer sequentially stacked on both sides of the negative electrode current collector from the inside to the outside.

[0067] The negative electrode current collector is a 10 μm copper mesh. The porosity of the copper mesh is 50%. The thickness of the conductive heat dissipation layer is 1 μm. The negative electrode active material layer was 80 μm. The thickness of the red phosphorus layer is 1 μm.

[0068] The conductive heat dissipation layer is made of the following raw materials: 5g binder polyvinylidene fluoride, 5g conductive agent graphene, and 80g nitrogen-phosphorus compound ammonium polyphosphate.

[0069] The negative electrode active material layer is made of the following raw materials: 90g of artificial graphite, 3g of graphene, and 4g of LA132 binder.

[0070] The preparation method of ...

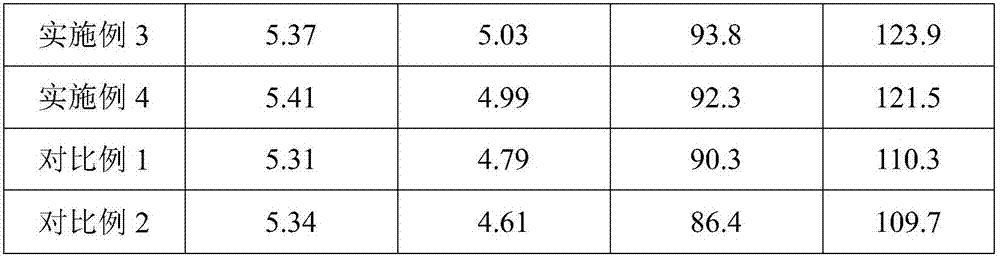

Embodiment 3

[0079] The composite negative electrode sheet in this embodiment includes a conductive heat dissipation layer, a negative electrode active material layer and a red phosphorus layer sequentially stacked on both sides of the negative electrode current collector from the inside to the outside.

[0080] The negative electrode current collector is a 15 μm copper foil. The thickness of the conductive heat dissipation layer is 5 μm. The negative electrode active material layer was 200 μm. The thickness of the red phosphorus layer is 3 μm.

[0081] The conductive heat dissipation layer is made of the following raw materials: 10g binder polyvinylidene fluoride, 10g conductive agent vapor-phase grown carbon fiber, and 90g nitrogen-phosphorus compound ammonium polyphosphate.

[0082] The negative electrode active material layer is made of the following raw materials: 95g of artificial graphite, 1g of vapor-phase grown carbon fiber, and 2g of LA132 binder.

[0083] The preparation meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com