Surface plasma nano-photocatalytic material as well as preparation method and application thereof

A technology of surface plasmons and catalytic materials, applied in the field of nano-photocatalytic materials, to achieve a wide range of photoresponse, ensure stability, and inhibit photocorrosion and decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

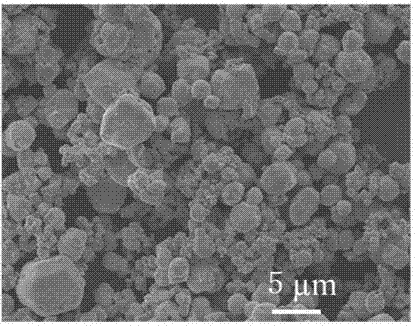

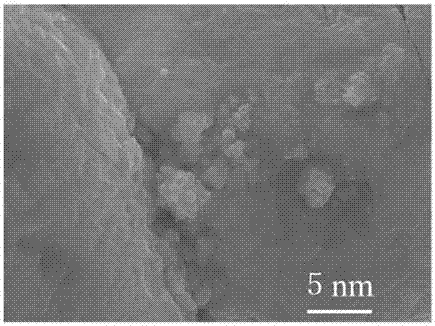

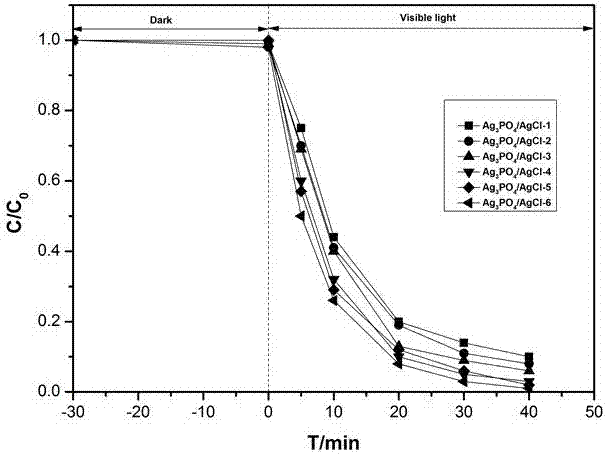

Image

Examples

Embodiment 1

[0033] (1) Ag 3 PO 4 Preparation: Weigh 1.275g NaH 2 PO 4 , dissolved in 50 ml of water, after being completely dissolved, 50 ml of AgNO with a concentration of 0.3 M was added dropwise under mechanical stirring 3 solution, and continued to stir for 5 hours at room temperature to obtain the photocatalyst Ag 3 PO 4 , washing with deionized water until the pH value of the washing solution is 6-7;

[0034] (2) Ag 3 PO 4 Preparation of / AgCl: to the Ag prepared in (1) 3 PO 488 ml of 0.1 M NaCl solution was added dropwise. Ag 3 PO 4 It is not only a template for the reaction but also provides Ag ions, through ion exchange in Ag 3 PO 4 AgCl is formed on the surface, which effectively strengthens the Ag 3 PO 4 stability. After stirring for 15 minutes, the obtained solution was centrifuged, washed with deionized water until the pH value of the washing solution was 6-7, and dried in a drying oven at 75°C to obtain the composite photocatalytic material Ag 3 PO 4 / AgCl-...

Embodiment 2

[0037] (1) Ag 3 PO 4 Preparation: weigh 1.1g NaH 2 PO 4 , dissolved in 50 ml of water, after being completely dissolved, 50 ml of AgNO with a concentration of 0.3 M was added dropwise under mechanical stirring 3 solution, and continued to stir for 5 hours at room temperature to obtain the photocatalyst Ag 3 PO 4 , washing with deionized water until the pH value of the washing solution is 6-7;

[0038] (2) Ag 3 PO 4 Preparation of / AgCl: to the Ag prepared in (1) 3 PO 4 70 ml of 0.1 M NaCl solution was added dropwise. Ag 3 PO 4 It is not only a template for the reaction but also provides Ag ions, through ion exchange in Ag 3 PO 4 AgCl is formed on the surface, which effectively strengthens the Ag 3 PO 4 stability. After stirring for 15 minutes, the obtained solution was centrifuged, washed with deionized water until the pH value of the washing solution was 6-7, and dried in a drying oven at 75°C to obtain the composite photocatalytic material Ag 3 PO 4 / AgCl-2...

Embodiment 3

[0041] (1) Ag 3 PO 4 Preparation: Weigh 0.8g NaH 2 PO 4 , dissolved in 50 ml of water, after being completely dissolved, 50 ml of AgNO with a concentration of 0.3M was added dropwise under mechanical stirring 3 solution, and continued to stir for 5 hours at room temperature to obtain the photocatalyst Ag 3 PO 4 , washing with deionized water until the pH value of the washing solution is 6-7;

[0042] (2) Ag 3 PO 4 Preparation of / AgCl: to the Ag prepared in (1) 3 PO 4 Add 60 ml of 0.1 M NaCl solution dropwise. Ag 3 PO 4 It is not only a template for the reaction but also provides Ag ions, through ion exchange in Ag 3 PO 4 AgCl is formed on the surface, which effectively strengthens the Ag 3 PO 4 stability. After stirring for 15 minutes, the obtained solution was centrifuged, washed with deionized water until the pH value of the washing solution was 6-7, and dried in a drying oven at 75°C to obtain the composite photocatalytic material Ag 3 PO 4 / AgCl-3;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com