Compound flocculant for papermaking wastewater and preparation method of compound flocculant

A technology of papermaking wastewater and flocculants, which is applied in chemical instruments and methods, processing wastewater treatment, flocculation/sedimentation water/sewage treatment, etc., can solve problems such as difficult to achieve ideal results, and achieve simple and easy preparation and use methods, Improve the number of recycling, the effect of low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Main reagents and instruments:

[0022] Epichlorohydrin (industrial grade, Baling Petrochemical Co., Ltd.), dimethylamine (industrial grade 40%, Huainan Jinling Zhongshen Chemical Factory), triethylenetetramine (industrial grade, Xiamen Dexin Chemical Co., Ltd.) , anhydrous ethanol (analytical pure), dadan yellow (analytical pure), cetyltrimethylammonium bromide (analytical pure), and papermaking wastewater were obtained from Zhejiang Yongtai Paper Industry Group.

[0023] 500mL three-neck flask, spherical condenser, 250mL constant pressure dropping funnel, DSX-120 digital display electric mixer (Hangzhou Instrument Motor Factory), GKC temperature-controlled water bath (Hangzhou Nuoding Science Equipment Co., Ltd.), PHS-25 type Acidity meter (Hangzhou Nuoding Scientific Equipment Co., Ltd.), NDJ-79 rotary viscometer, MY3000-6H intelligent coagulation test agitator (Qianjiang Meiyu Instrument Co., Ltd.).

[0024] Flocculant Synthesis:

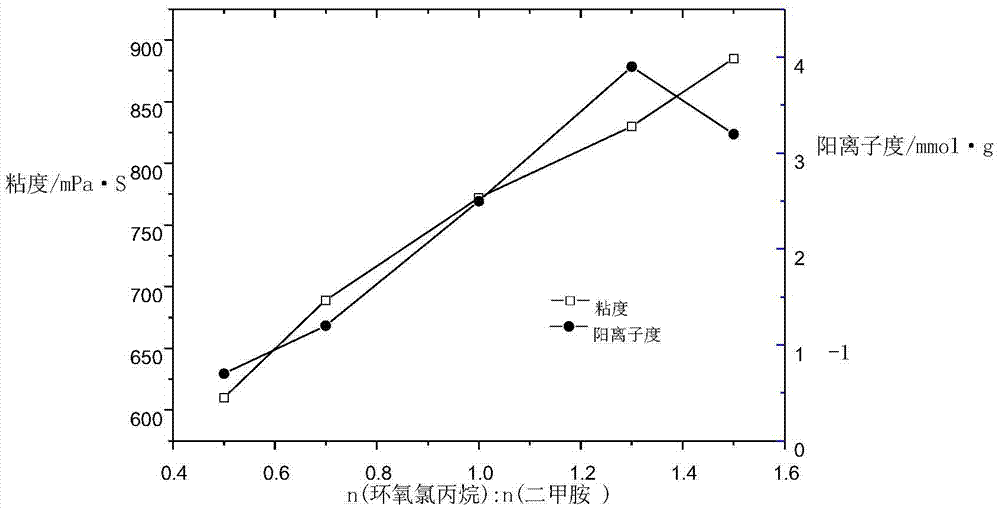

[0025] The reaction is carried o...

Embodiment 2

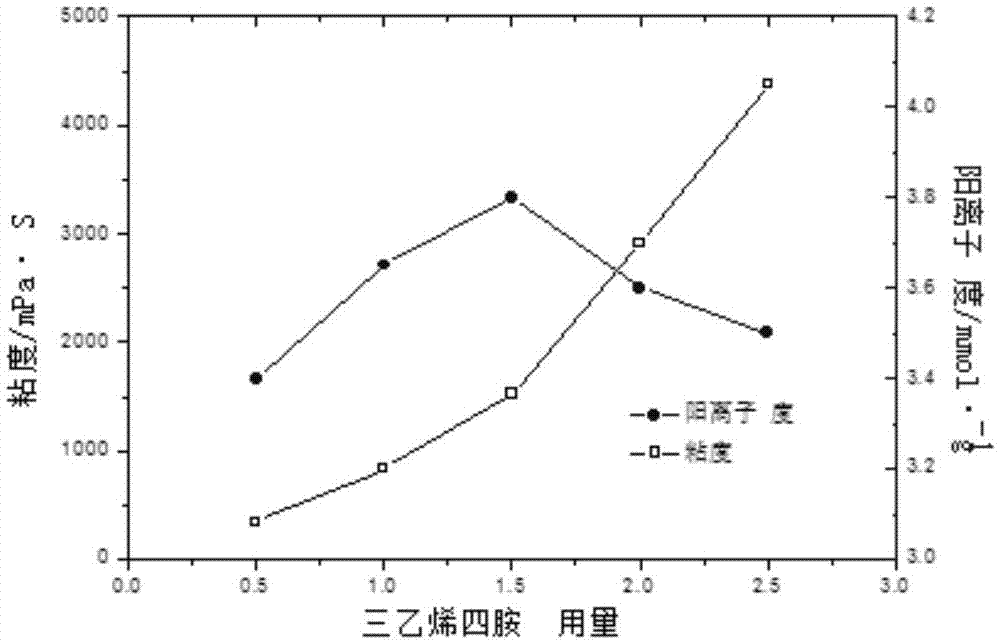

[0038] With embodiment 1, other reaction conditions are constant, investigate modifier triethylenetetramine consumption on the influence of polymer viscosity and cationic degree, experimental result is as follows figure 2 shown.

[0039] Depend on figure 2 It can be seen that with the increase of the amount of triethylenetetramine, the product viscosity increases gradually. When the amount of triethylenetetramine exceeds 2.5% of the total polymer, gel appears in the product solution, and the water solubility of the polymer becomes poor. The degree of cation increases when the amount of triethylenetetramine is less than 1.5%, and reaches the maximum when the amount of triethylenetetramine is higher than 1.5%, the degree of cation decreases. In the reaction, triethylenetetramine can partially cross-link the polymer chains, and the degree of polymerization increases with the increase of the dosage. Poor, so there will be an increase in viscosity but a decrease in cationicity...

Embodiment 3

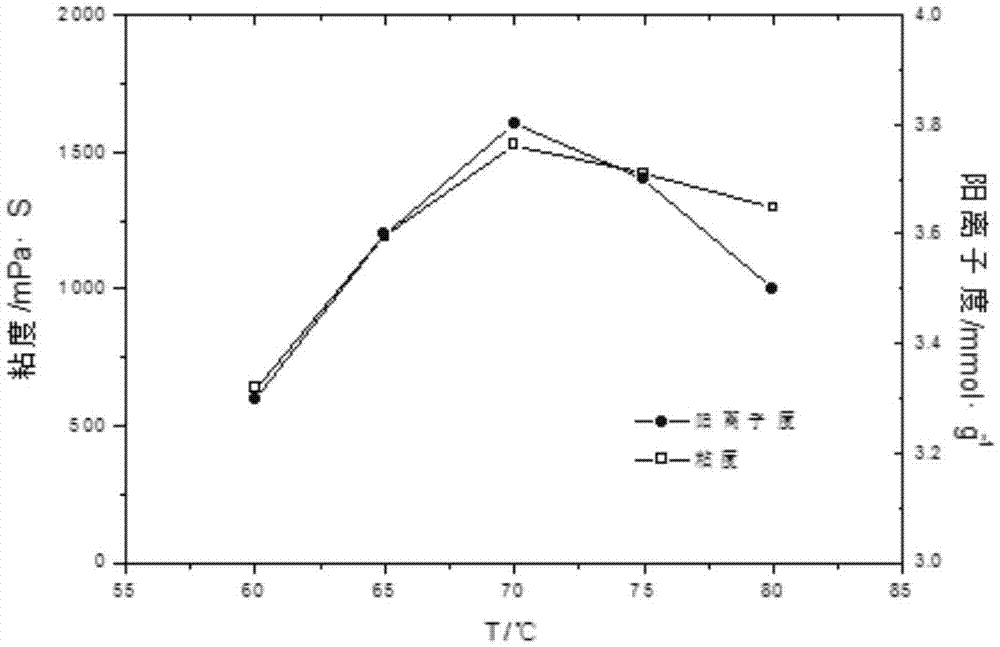

[0041]With embodiment 1, other reaction conditions are constant, investigate the influence of reaction temperature on polymer viscosity and cationic degree, experimental result is as follows image 3 shown.

[0042] Depend on image 3 It can be seen that the change trend of polymer viscosity and cationic degree with temperature is basically the same. When the temperature is lower than 70°C, both of them increase with the increase of temperature, and reach the maximum value at 70°C; when the temperature is higher than 70°C, the viscosity and cationicity decrease with the increase of temperature. The reaction between triethylenetetramine and epoxy group is a nucleophilic substitution reaction. If the temperature is too low, the reactant molecules cannot be fully activated, and there is not enough energy to overcome the steric hindrance between molecules, resulting in a slower reaction rate; The reaction is an exothermic reaction, and if the temperature is too high, it will hin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com