Mold-proof anti-microbial tile joint mixture and preparation method thereof

An anti-mildew antibacterial agent, anti-mildew antibacterial technology, applied in the field of tile grout, can solve the problems of anti-mildew, unsatisfactory environmental protection effect, mildew breeding bacteria, trouble in life, etc. The effect of bonding force, reducing cracks, and improving the strength of caulking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

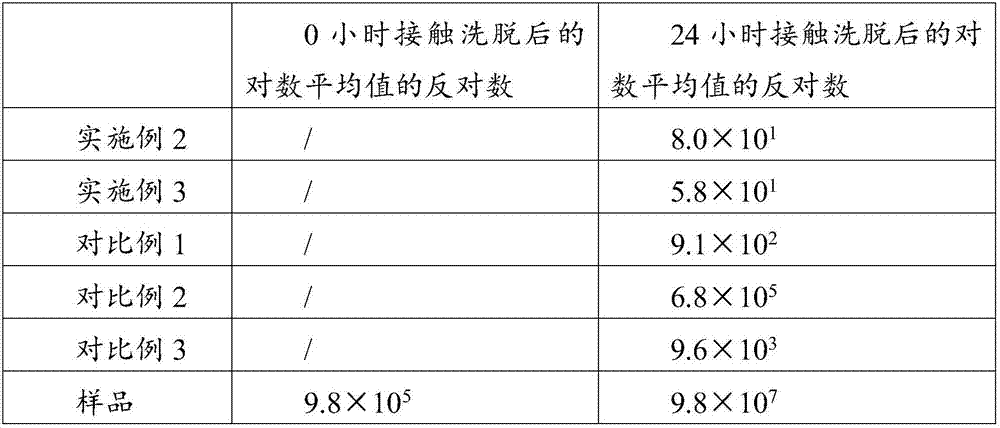

Examples

Embodiment 1

[0021] Preparation of nano magnesium oxide modified chitosan antibacterial agent.

[0022] 1) Weigh MgCl 2 Dissolve in absolute ethanol, add PEG400 as dispersant. After mixing evenly, raise the temperature to 50-60°C, and slowly add a certain amount of ammonia-water-ethanol solution with a volume ratio of (1:1) dropwise under continuous magnetic stirring to form a white precipitate. After dripping, continue the heat preservation reaction for 1.5h, take it out, and let it stand at room temperature for aging. The precipitate was separated by filtration, and the filter cake was washed several times with water and ethanol respectively, and dried in vacuum at 60°C to obtain a white precursor. Finally, it was calcined at 500° C. for 1.5 h in an air atmosphere to obtain nano-magnesia powder.

[0023] 2) Add the nano-magnesia powder into absolute ethanol and stir evenly, ultrasonically disperse, the ultrasonic frequency is 40KHz, and the ultrasonic dispersion time is 15min, to form...

Embodiment 2

[0027] 1. Formula preparation (parts by weight)

[0028] 25 parts of vinyl acetate-ethylene copolymer emulsion;

[0029] Potassium methyl siliconate 0.8 parts;

[0030] 60 parts of 200-400 mesh quartz powder;

[0031] 0.3 parts of carbendazim;

[0032] 0.3 part of nano magnesium oxide modified chitosan antibacterial agent prepared by embodiment 1;

[0033] 0.3 parts of hydroxypropyl methylcellulose;

[0034] 0.2 parts of silicone water repellent;

[0035] 1.5 parts of glycerol;

[0036] 1.0 parts of film-forming aid

[0037] 2. Preparation:

[0038] According to the above formula, mix preservatives, anti-mold and antibacterial agents, silicone water-repellent agents, film-forming aids, and half the amount of elastic emulsion, then add them to the disperser for dispersion, and then add 200-400-mesh quartz powder, formazan Potassium silanolate and optional water glass, after feeding, increase the speed to 1000 rpm, disperse for 20 minutes; reduce the speed to 500 rpm, slow...

Embodiment 3

[0040] 1. Formula preparation (parts by weight)

[0041] 20 parts of vinyl acetate-ethylene copolymer emulsion;

[0042] Potassium methyl siliconate 1.0 part;

[0043] 55 parts of 200-400 mesh quartz powder;

[0044] Carbendazim 0.2 parts;

[0045] 0.3 part of nano magnesium oxide modified chitosan antibacterial agent prepared by embodiment 1;

[0046] 0.2 parts of hydroxypropyl methylcellulose;

[0047] 0.1 parts of silicone water repellent;

[0048] 2.0 parts of ethylene glycol;

[0049] Coalescing aid 1.5 parts

[0050] 2. Preparation:

[0051] According to the above formula, mix preservatives, anti-mold and antibacterial agents, silicone water-repellent agents, film-forming aids, and half the amount of elastic emulsion, then add them to the disperser for dispersion, and then add 200-400-mesh quartz powder, formazan Potassium silanolate and optional water glass, after feeding, increase the speed to 1000 rpm, disperse for 20 minutes; reduce the speed to 500 rpm, slow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com