Rubber intensifier as well as preparation method and application thereof

A rubber reinforcement and raw material technology, applied in the field of rubber materials, can solve problems such as unsatisfactory effects and damage to the flexibility of rubber products, and achieve the effects of avoiding unclean scrubbing, inhibiting the aging process, and improving physical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

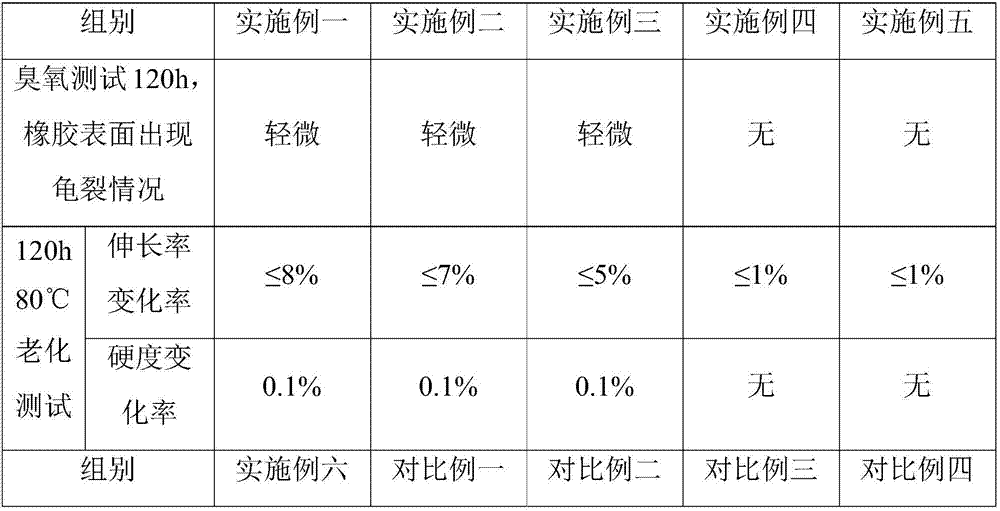

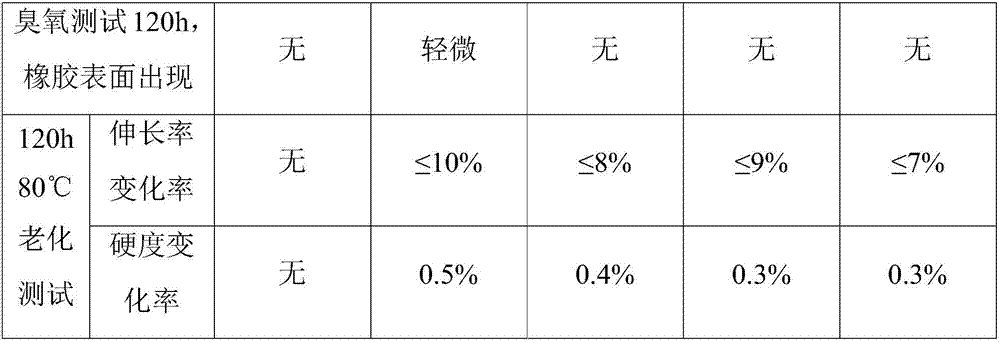

Examples

preparation example Construction

[0021] Preferably, the preparation method of cashew nut oil comprises the following steps: S101: uniformly mix cashew kernels and absolute ethanol at a mass ratio of 100:(10-15), and then heat at 80-95°C for 60-70 minutes; S102: mix cashew nut shells Crush to obtain cashew nut powder with a particle size of less than 0.15mm, and dry the cashew nut powder at 55-65°C until the water content is less than or equal to 5%; S103: Mix the product obtained in S101 and the product obtained in S102 evenly, and then use twin-screw oil extraction Machine carries out low-temperature pressing, and the temperature of low-temperature pressing is 45~50 ℃, and the crude oil obtained by low-temperature pressing is filtered, and filtrate is collected, and cashew nut oil is obtained; Wherein, the mass ratio of the product that S101 obtains and the product that S102 obtains is 100:(20 ~30).

[0022] In addition, the present invention also provides the preparation method of above-mentioned rubber rei...

Embodiment 1

[0026] This embodiment provides a rubber reinforcing agent, the raw material components are by weight, including: 20 parts by weight of cashew nut oil and 18 parts by weight of hexamethylenetetramine;

[0027] Wherein, the preparation method of cashew nut oil comprises the following steps: S101: uniformly mix cashew kernels and absolute ethanol at a mass ratio of 100:10, and then heat at 80° C. for 60 minutes; S102: crush cashew nut shells to obtain cashew nuts with a particle size of less than 0.15 mm powder, dry the cashew nut powder at 55°C until the water content is less than or equal to 5%; S103: mix the product obtained in S101 and the product obtained in S102 evenly, and then use a twin-screw oil press for low-temperature pressing, and the temperature of the low-temperature pressing is 45 °C, filter the crude oil obtained by low-temperature pressing, collect the filtrate, and obtain cashew nut oil; wherein, the mass ratio of the product obtained in S101 and the product o...

Embodiment 2

[0031] This embodiment provides a rubber reinforcing agent, the raw material components are calculated in parts by weight, including: 30 parts by weight of cashew nut oil and 12 parts by weight of hexamethylenetetramine;

[0032]Wherein, the preparation method of cashew nut oil comprises the following steps: S101: uniformly mix cashew kernels and absolute ethanol at a mass ratio of 100:15, and then heat at 95° C. for 70 minutes; S102: crush cashew nut shells to obtain cashew nuts with a particle size of less than 0.15 mm powder, dry the cashew powder at 65°C until the water content is less than or equal to 5%; S103: mix the product obtained in S101 and the product obtained in S102 evenly, and then use a twin-screw oil press for low-temperature pressing, and the temperature of the low-temperature pressing is 50 °C, filter the crude oil obtained by low-temperature pressing, collect the filtrate, and obtain cashew nut oil; wherein, the mass ratio of the product obtained in S101 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com