U-shaped wood-plastic canal lining and manufacturing method thereof

A manufacturing method and wood-plastic technology, applied in irrigation pipelines, applications, buildings, etc., can solve the problems of increasing the water conveyance roughness of the channel, the water content of the channel structure is large, and the water conveying capacity is reduced, and achieves good anti-seepage effect and waterproof. The effect of good anti-seepage performance and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

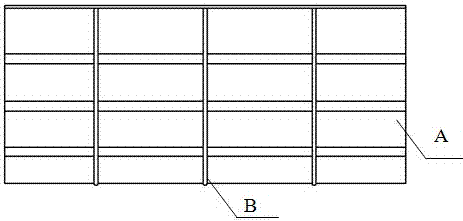

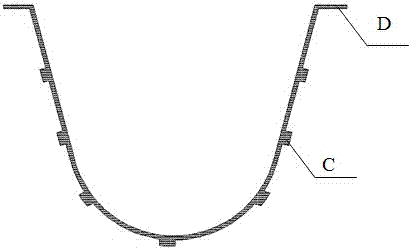

[0023] Specific implementation mode one: as figure 1 and figure 2 As shown, what is described in this embodiment is a U-shaped wood-plastic channel lining. The U-shaped wood-plastic channel lining is formed by connecting a plurality of U-shaped groove shell-shaped units A in sequence, and each U-shaped groove shell-shaped unit A The outer surface of the body A is uniformly provided with a plurality of annular reinforcing ribs B along the horizontal direction, and the outer surface of each U-shaped groove shell-shaped monomer A is uniformly provided with a plurality of long strip-shaped reinforcing ribs C along the longitudinal direction, and the U-shaped wood-plastic channel lining The two ends of the top are respectively provided with lugs D along the longitudinal direction, and the plurality of annular reinforcing ribs B, the plurality of elongated reinforcing ribs C, the two lugs D and the plurality of U-shaped groove shell-shaped monomers A are integrated (It is processe...

specific Embodiment approach 2

[0024] Specific implementation mode two: as figure 1 As shown, the U-shaped wood-plastic channel lining described in Embodiment 1, the wall thickness of the U-shaped wood-plastic channel lining is 6-12mm, and the length of each U-shaped groove shell-shaped monomer A is 1~1.5m, the height of each U-shaped groove shell-shaped monomer A is 400~600mm, and the diameter of the inner bottom surface circle of each U-shaped groove shell-shaped monomer A is 250~350mm.

specific Embodiment approach 3

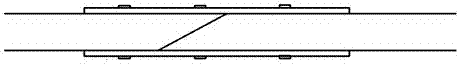

[0025] Specific implementation mode three: as image 3 As shown, in the U-shaped wood-plastic channel lining described in Embodiment 1 or 2, every two adjacent U-shaped groove shell-shaped monomers A are connected by a half-lap joint of cuts.

[0026] Specific implementation mode four: as image 3 As shown, in the U-shaped wood-plastic channel lining described in Embodiment 3, the incisions between two adjacent U-shaped groove shell-shaped monomers A are connected by glue joints and semi-lap joints (firstly Use sandpaper to polish the cut surface of the joint, and apply a silane coupling agent solution to increase the bonding strength of the wood-plastic composite surface. After standing for 20-30 minutes, apply the adhesive evenly on the joint to achieve cementation and half-lap connection).

[0027] Specific implementation mode five: as image 3 As shown, for a U-shaped wood-plastic channel lining described in Embodiment 4, the bonding width of the inner and outer surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com