Test method for evaluating contractility of neat cement paste

A technology for cement slurry and shrinkage performance, applied in the field of concrete, can solve the problems of large difference in test results and high cost of test methods, and achieve the effects of low cost, stable test data and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

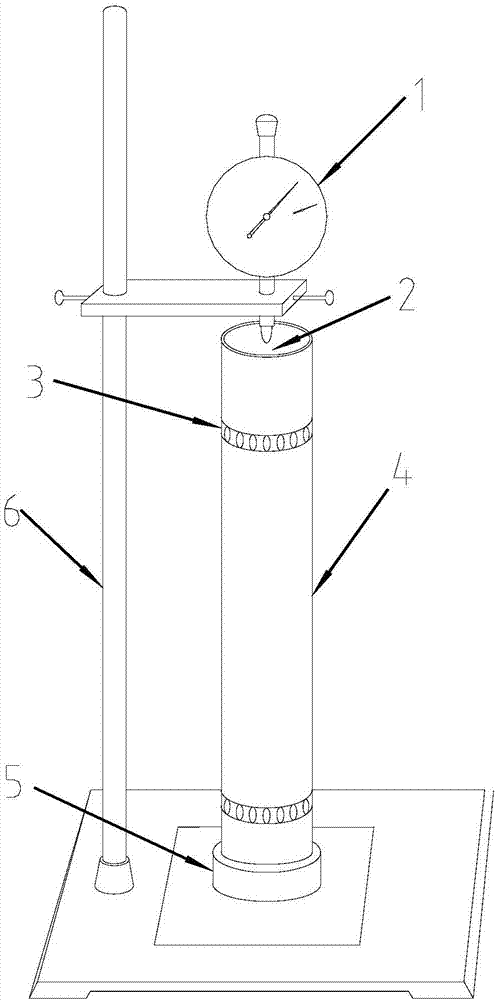

[0021] like figure 1 Shown, be a kind of embodiment of the present invention, a kind of test method of evaluating the shrinkage performance of cement slurry, make detachable mold and fix it on the supporting structure; Make cement slurry and pour in the detachable mold, record The original length of the test piece is L; a sealant is poured on the cement paste to seal it, and a metal sheet 2 is placed after the sealant cools, and the length of the test piece is measured with a measuring device and the initial reading is recorded l 0 ; Every once in a while, record the reading l of the measuring device at time t t ;Remove the detachable mold 3 days after pouring, and continue to measure and record the length of the test piece until the test is terminated on 28 days, which can realize the shrinkage measurement of the whole process of cement paste self-pouring; calculate the strain ε of cement paste t , get the shrinkage strain of the cement paste at time t, and draw the strain c...

Embodiment 2

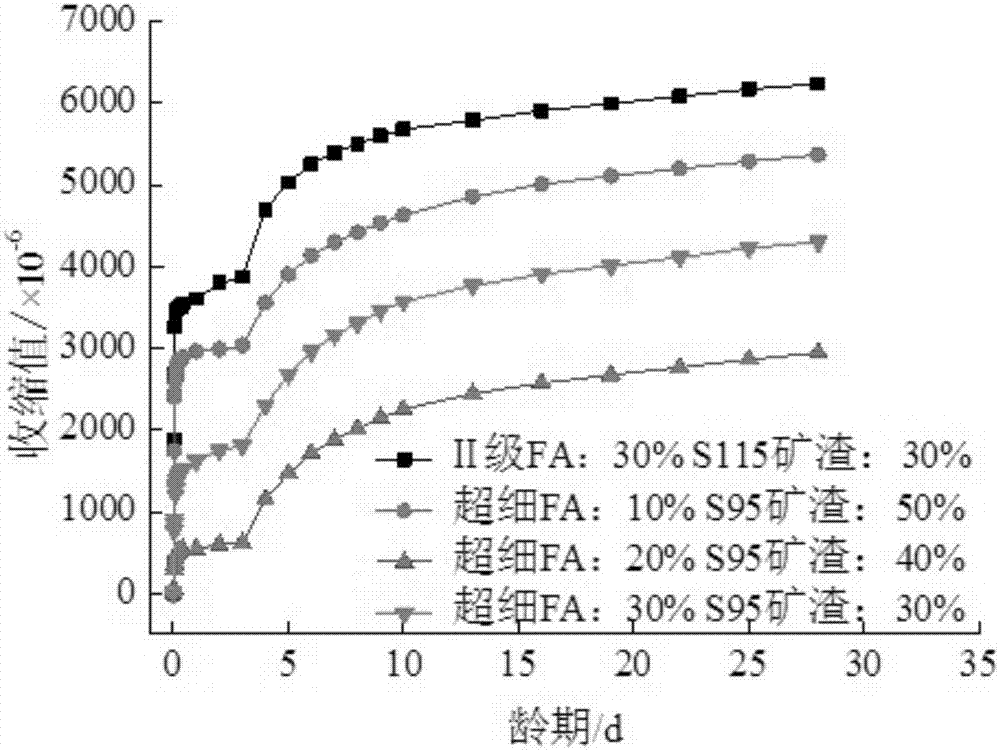

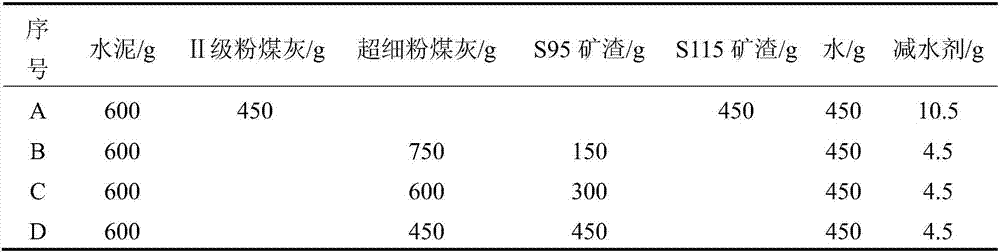

[0031] By adjusting the fineness and dosage of fly ash and slag, four groups of cementitious materials with a mineral admixture content of 60% were prepared to study the influence of mineral admixtures on the shrinkage value of cement paste. See Table 1 for details. Test results such as figure 2 shown.

[0032] Table 1 test mix ratio

[0033]

[0034] Depend on figure 2 It can be seen that the shrinkage values of cement-based materials mixed with different finenesses and amounts of fly ash and slag are significantly different, and the shrinkage curves of cement pastes with different mix ratios are basically the same, and the stability of the test data is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com