Coarse-grained molecular dynamic method for analyzing graphene assembly

A technology of molecular dynamics and graphene, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as complex modeling process, unsuitable for complex system research, and inability to predict the accurate assembly structure of assemblies. The effect of simple construction and accurate mechanical behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

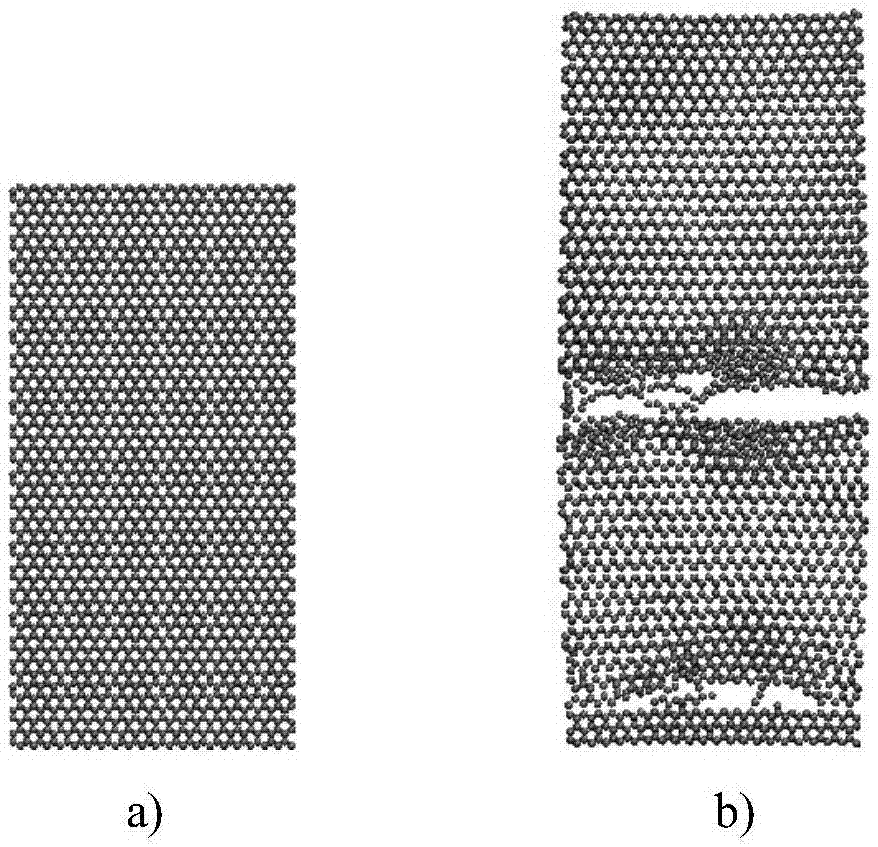

[0029] Coarse-grained molecular dynamics simulation of tensile failure of bilayer graphene

[0030] Establish a coarse-grained bilayer graphene model with a length of 20nm and a width of 10nm, such as figure 1 As shown in a), the coordinates of the initial structure are saved in the coordinate file. The LAMMPS program is used to perform sufficient energy relaxation on the graphene coarse-grained model to obtain the optimal configuration. The bottom 1nm of the bilayer graphene is fixed, and a force of 0.5nN is applied to all the coarse particles at the top 1nm, and finally the bilayer graphene is broken, as shown in figure b).

Embodiment 2

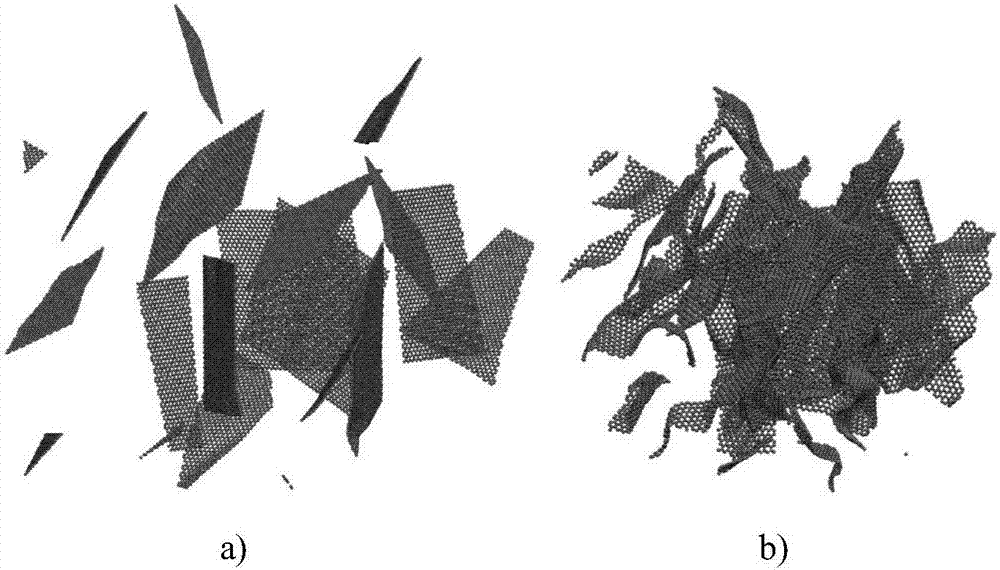

[0032] Coarse-grained molecular dynamics model of graphene airgel

[0033] Create a single-layer graphene with a length and width of 5nm in the Accelrys Material Studio software, and use 10 pieces of graphene to build a density of 0.2g / cm 3 The amorphous block structure, such as figure 2 In a) shown. Then, all atomic coordinates are exported, multiplied by 2, and saved as a coordinate file that can be read by LAMMPS. Using the LAMMPS program, hydrostatic pressure is applied to the amorphous structure, and the graphene sheets self-assemble into an airgel structure, as shown in Figure b).

Embodiment 3

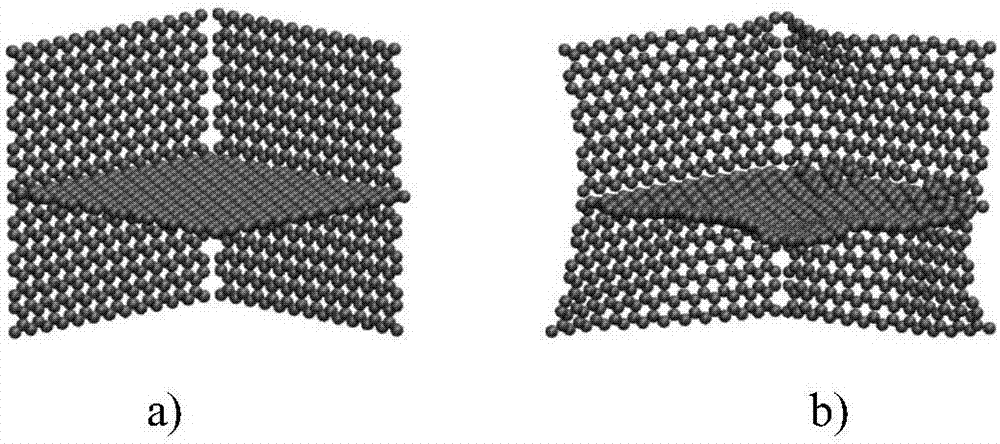

[0035] Coarse-grained molecular dynamics simulation of three-dimensional overlapping of graphene

[0036] In the Accelrys Material Studio software, three sheets of single-layer graphene with a length and width of 5nm are established, and press image 3 In a) put together. At this time, each sheet of graphene is independent of each other, and there is no covalent bond between them. Then, all atomic coordinates are exported, multiplied by 2, and saved as a coordinate file that can be read by LAMMPS. The energy relaxation of the system was performed using the LAMMPS program. During the energy relaxation process, the three graphene sheets automatically formed covalent linkages and self-assembled into a three-dimensional structure.

[0037] Figure 4 It is the coarse-grained mapping of graphene molecular dynamics model; a) is the coordinates of all atoms; b) is the coordinates of coarse grains.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com