Composite shell for electronic product and making method of composite shell

A technology for electronic products and manufacturing methods, which is applied in the field of composite casings for electronic products and its manufacturing, can solve problems such as high cost, poor plasticity, and difficult machining, and achieve low loss of stainless steel, low cost, and solve difficult cutting processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

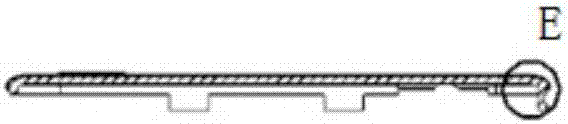

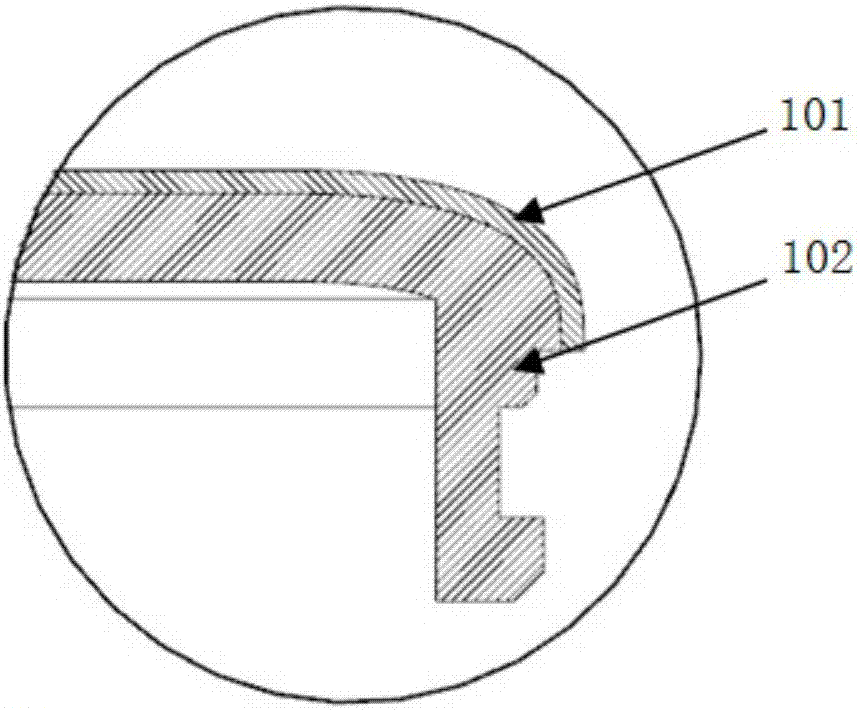

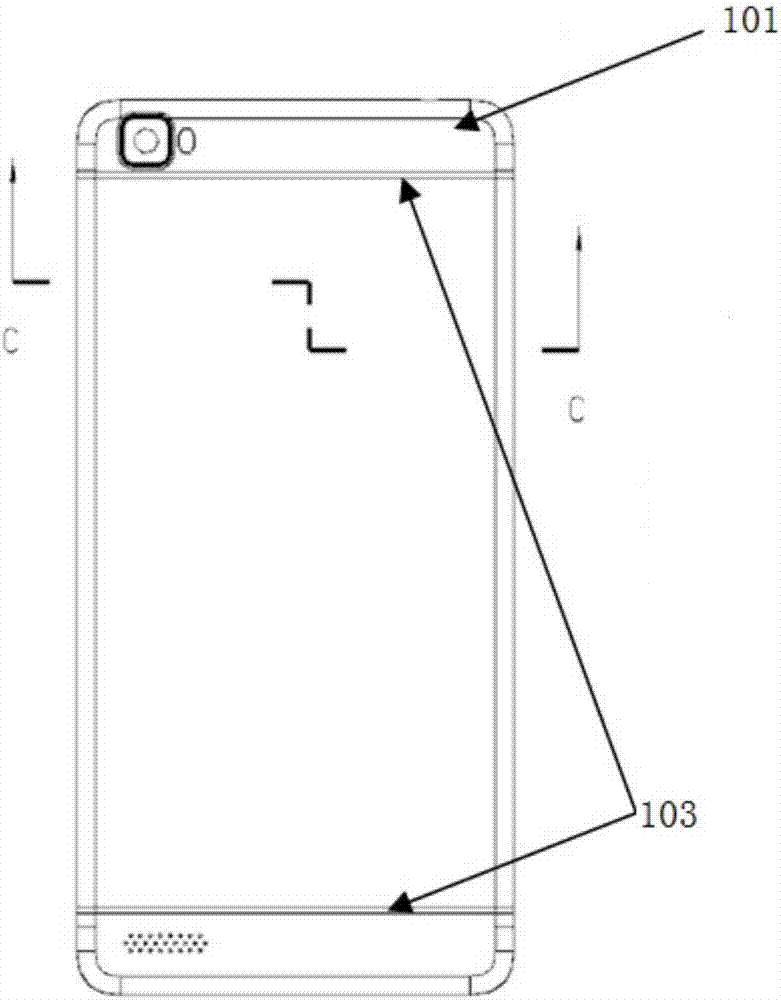

[0047] refer to Figure 1a to Figure 1c , in one embodiment, a composite housing for electronic products, including a stacked appearance side stainless steel plate 101 and a non-appearance side plate 102, the appearance side stainless steel plate 101 and the non-appearance side The side plates 102 are combined through penetration welding spots formed by laser perforation welding on the non-appearance side plates 102 .

[0048] In a preferred embodiment, the non-appearance side plate 102 is an aluminum alloy plate.

[0049] In a preferred embodiment, the penetration welding spots are uniformly arranged on the non-appearance side plate 102 .

[0050] In a preferred embodiment, the gap between the plates does not exceed 10% of the minimum thickness of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com