Tube heating furnace for producing crude oil

A tubular heating furnace and crude oil technology, applied in water heaters, fluid heaters, lighting and heating equipment, etc., can solve problems such as burns, inability to dissipate heat and cool down, and inconspicuous heat protection effects, and achieve easy maintenance and good Promote the effect of using value and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

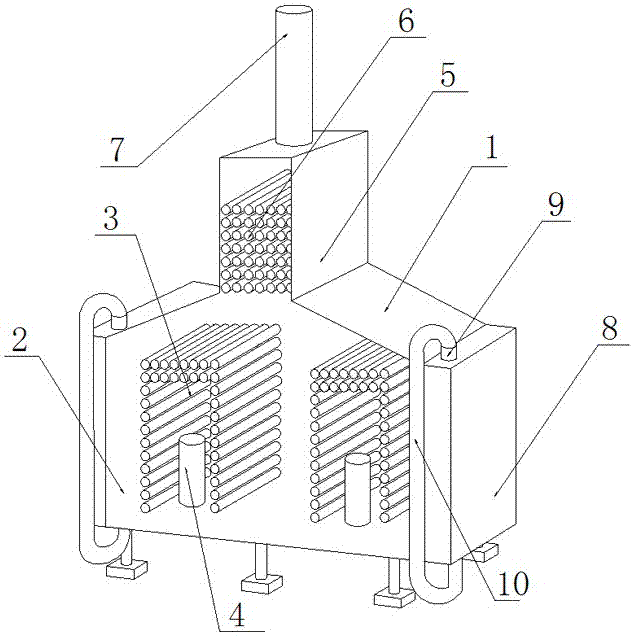

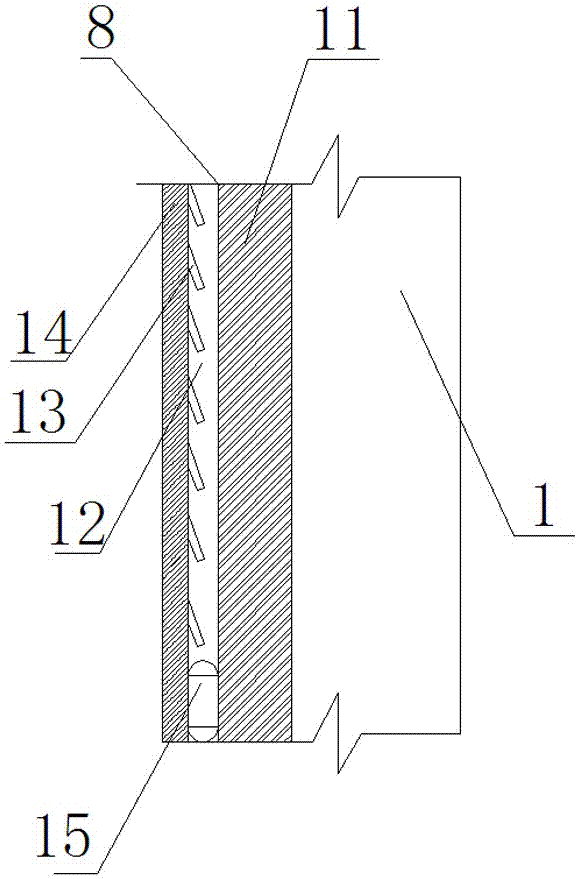

[0019] Such as Figure 1-2 As shown, the present invention provides a tubular heating furnace for crude oil production, comprising a furnace wall 1, the inside of the furnace wall 1 is provided with a radiation chamber 2, and the inside of the radiation chamber 2 is respectively provided with several furnace tubes 3, and the furnace tube 3 A burner 4 is provided at the bottom, a waste heat recovery tank 5 is provided on the top of the furnace wall 1, a waste heat recovery section 6 is provided inside the waste heat recovery tank 5, and a smoke exhaust pipe 7 is provided on the top of the waste heat recovery tank 5, and the two sides of the furnace wall 1 A cooling layer 8 is provided on the side, a water pipe joint 9 is provided on the top of the cooling layer 8, a water pipe 10 is provided on one side of the water pipe joint 9, a temperature insulation layer 11 is provided inside the cooling layer 8, and a temperature insulation layer 11 is provided on one side The cooling pi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap