Mushroom spicy sauce

A technology of spicy sauce and mushrooms, applied in the field of food or food materials, can solve the problem of uneven taste of mushrooms, achieve the effect of enhancing the ability to resist diseases and promoting the absorption of calcium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

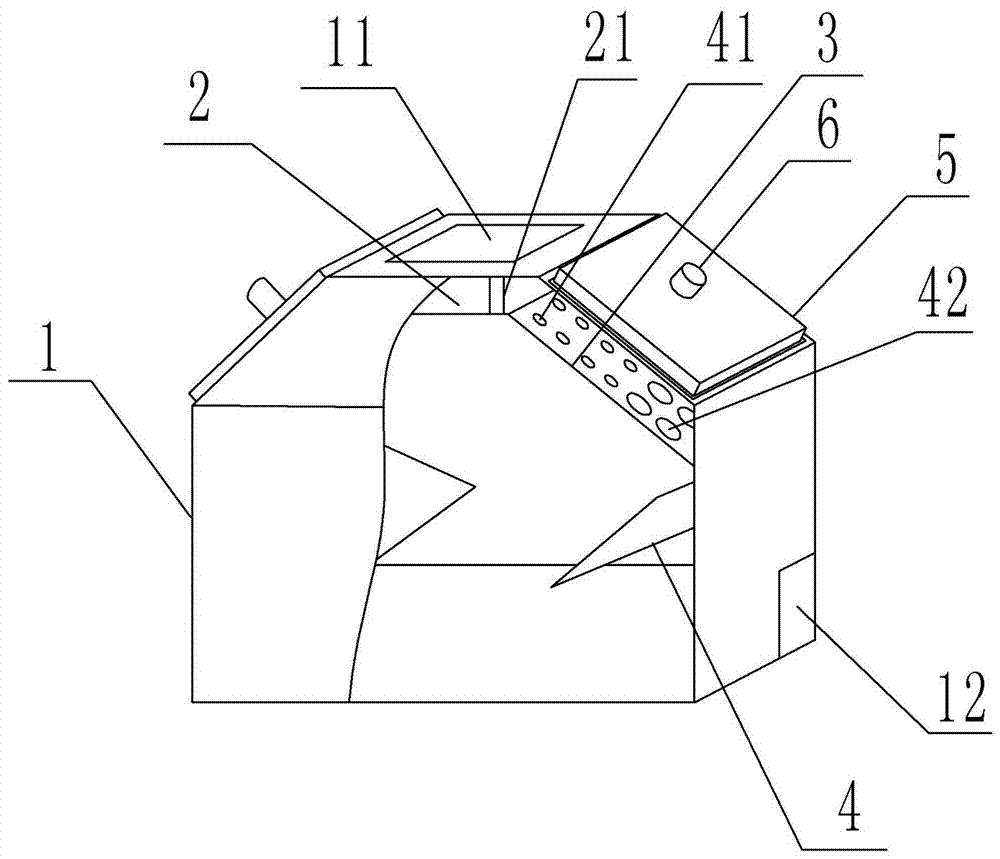

Image

Examples

Embodiment 1

[0026] Mushroom spicy sauce, including the following raw materials, mushroom 6kg, oyster mushroom 2.5kg, salt 40kg, monosodium glutamate 100g, vinegar 125ml, white vinegar 100ml, sucrose 400g, spicy sauce 300g, capsicum pigment 35g, sorghum pigment 20g, edible agar 0.1kg, this The mushrooms in the plan are shiitake mushrooms, and the steps of making the mushroom spicy sauce are as follows:

[0027] Step 1, mushroom and oyster mushroom treatment: wash the mushrooms and oyster mushrooms with water, put the mushrooms in the sun to dry, the moisture content of the dried mushrooms is 20%, and then put the mushrooms into the baking equipment at 30°C for baking , every hour, raise the temperature of the baking equipment by 5°C, and the maximum temperature is lower than 50°C; when the moisture content of the mushroom is 11%, stop baking;

[0028] Step 2, making sauce water: mixing salt, monosodium glutamate, vinegar, white vinegar, sucrose, spicy sauce, capsicum pigment, and sorghum p...

Embodiment 2

[0036] Mushroom spicy sauce, including the following raw materials, mushroom 7kg, oyster mushroom 4kg, salt 43kg, monosodium glutamate 110g, vinegar 128ml, white vinegar 130ml, sucrose 410g, spicy sauce 320g, capsicum pigment 38g, sorghum pigment 23g, edible agar 0.3kg; The mushrooms in the recipe are shiitake mushrooms, and the preparation steps of the mushroom spicy sauce are as follows:

[0037] Step 1, mushroom and oyster mushroom treatment: wash the mushrooms and oyster mushrooms with water, put the mushrooms in the sun to dry, the moisture content of the dried mushrooms is 20%, and then put the mushrooms into the baking equipment at 30°C for baking , every 1.5 hours, raise the temperature of the baking equipment by 5°C, and the maximum temperature is lower than 50°C; when the moisture content of the mushrooms is 12%, stop baking;

[0038] Step 2, making sauce water: mixing salt, monosodium glutamate, vinegar, white vinegar, sucrose, spicy sauce, capsicum pigment, and sor...

Embodiment 3

[0046] Mushroom spicy sauce, including the following raw materials, mushroom 10kg, oyster mushroom 5kg, salt 45kg, monosodium glutamate 120g, vinegar 135ml, white vinegar 150ml, sucrose 420g, spicy sauce 350g, capsicum pigment 40g, sorghum pigment 25g, edible agar 0.5kg; The mushrooms in the recipe are shiitake mushrooms, and the preparation steps of the mushroom spicy sauce are as follows:

[0047] Step 1, mushroom and oyster mushroom treatment: wash the mushrooms and oyster mushrooms with water, put the mushrooms in the sun to dry, the moisture content of the dried mushrooms is 20%, and then put the mushrooms into the baking equipment at 30°C for baking , every 1h to 2h, raise the temperature of the baking equipment by 5°C, and the maximum temperature is lower than 50°C; when the moisture content of the mushroom is 13%, stop baking;

[0048] Step 2, making sauce water: mixing salt, monosodium glutamate, vinegar, white vinegar, sucrose, spicy sauce, capsicum pigment, and sorg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com