Preparation method of composite shell coated liquid isocyanate self-repairing microcapsule

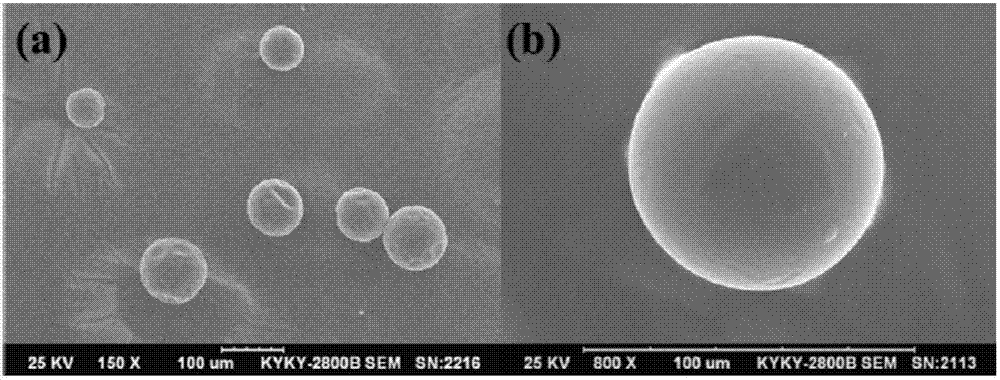

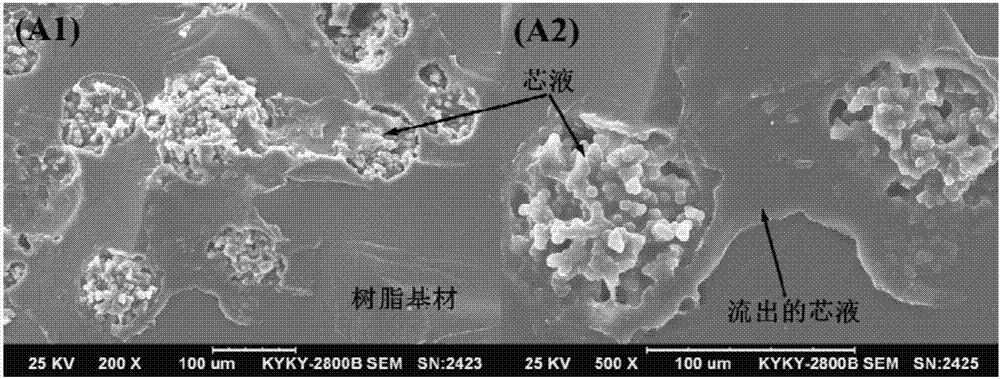

A technology for self-repairing microcapsules and isocyanates, applied in microcapsule preparations, microsphere preparation and other directions, can solve the problems of fragility, poor microcapsule strength, high active core liquid outflow, etc., and achieves good particle size controllability and cost. Inexpensive, smooth-looking results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

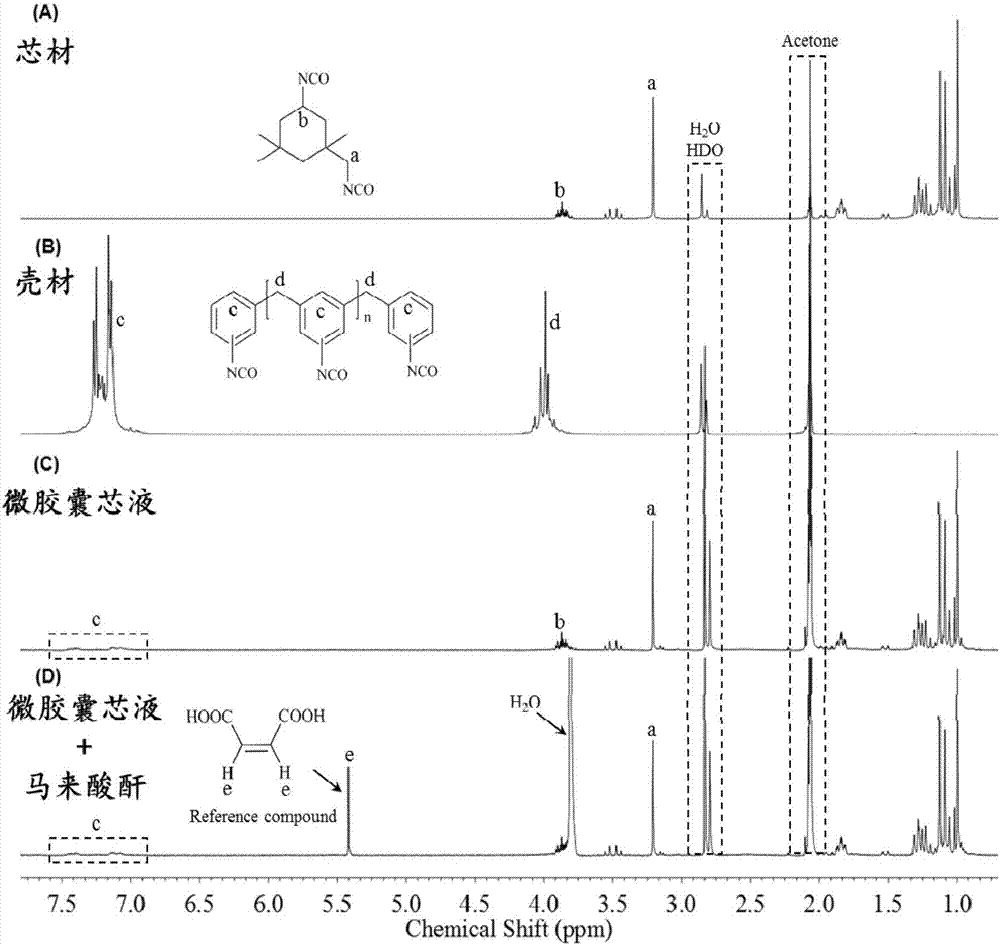

Embodiment 1

[0028] At room temperature, add polyvinyl alcohol with a degree of alcoholysis of 95% and a molecular weight of 70000-80000 g / mol into deionized water and stir for 30 minutes, then heat to 80 °C and stir for 3 hours. Finally cooling to obtain 5wt% polyvinyl alcohol aqueous solution. Take 60ml of the prepared polyvinyl alcohol aqueous solution and stir at 1600rpm, then mix 12g of isophorone diisocyanate and 4 g of polyphenyl polymethylene polyisocyanate into a homogeneous oil phase and slowly pour it into the polyvinyl alcohol aqueous solution for emulsification for 4min Forms a stable oil-in-water emulsion. 0.025 g, 0.050 g, 0.100 g, 0.200 g, 0.400 g, and 0.800 g of diethylenetriamine were respectively dissolved in 10 ml of deionized water to prepare 6 equal parts of diethylenetriamine solutions. Six parts of diethylenetriamine solutions were added dropwise from low concentration to high concentration into the stable oil-in-water emulsion, and each part of diethylenetriamine ...

Embodiment 2

[0030] At room temperature, add polyvinyl alcohol with a degree of alcoholysis of 98% and a molecular weight of 170,000-180,000 g / mol into deionized water and stir for 30 minutes, then heat to 95°C and stir for 1.5 hours. Finally cooled to obtain 2wt% polyvinyl alcohol aqueous solution. Get 60ml of the prepared polyvinyl alcohol aqueous solution and stir at 600rpm, then mix 12 g of isophorone diisocyanate and 4 g of polyphenyl polymethylene polyisocyanate into a homogeneous oil phase and slowly pour it into the polyvinyl alcohol aqueous solution for emulsification 4 min to form a stable oil-in-water emulsion. 0.030 g, 0.060 g, 0.120 g, 0.240 g, 0.480 g, and 0.960 g of diethylenetriamine were respectively dissolved in 10 ml of deionized water to prepare 6 equal parts of diethylenetriamine solutions. After emulsification, 6 parts of diethylenetriamine solution were added dropwise to the emulsion successively, and each part of diethylenetriamine solution was added at an interval...

Embodiment 3

[0032]At room temperature, add polyvinyl alcohol with 85% alcoholysis degree and molecular weight of 20000-30000g / mol into deionized water and stir for 30min, then heat to 70°C and stir for 5h. Finally cooled to obtain 12wt% polyvinyl alcohol aqueous solution. Get 60 ml of prepared polyvinyl alcohol aqueous solution and stir at 400rpm, then 12g isophorone diisocyanate and 4g polyphenyl polymethylene polyisocyanate are mixed into a homogeneous oil phase and slowly poured into the polyvinyl alcohol aqueous solution for emulsification 4 min to form a stable oil-in-water emulsion. Dissolve 0.015g, 0.030g, 0.060g, 0.120g, 0.240g, and 0.480g of diethylenetriamine in 10 ml of deionized water respectively to prepare 6 equal parts of diethylenetriamine solutions. After emulsification, 6 parts of diethylenetriamine solution were added dropwise to the emulsion successively, and each part of diethylenetriamine solution was added at an interval of 10 min. After the dropwise addition was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com