A small experimental device for solid phase polymerization

A technology of solid-phase polymerization and experimental equipment, which is applied in the direction of chemical/physical/physical-chemical fixed reactors, etc., can solve the problems of large investment, poor reaction temperature uniformity, inconvenient operation, etc., achieve small size, improve reaction temperature uniformity , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

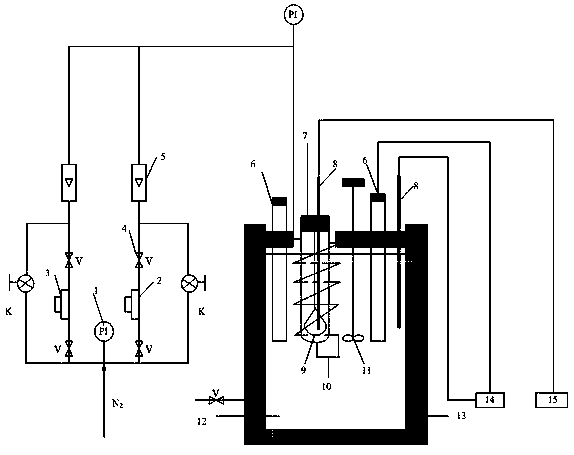

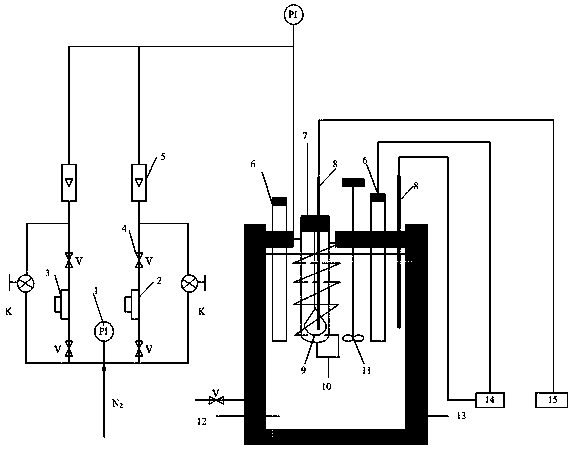

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0024] Such as figure 1 shown.

[0025] A small solid-phase polymerization experimental device, which is mainly composed of a nitrogen flow control system, a heat conduction oil heating and temperature control system, and a reactor system. The heat oil pool 13 and the reactor 7 are important components, and the electric heating rod 6 is inserted into the heat conduction system. The heat-conducting oil 12 injected therein is heated in the oil pool 13, and the electric heating rod 6 is controlled by the heating controller 14, which is characterized in that the reactor 7 is inserted into the heat-conducting oil 12 through the opening on the sealing cover of the heat-conducting oil pool 13 In the reactor 7, a micro-silo 9 is installed, and the nitrogen coil 10 is coiled on the reactor 7. The inlet end of the nitrogen gas is connected to the gas source, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com