Natural latex for weather balloons and preparation method thereof

A technology of natural rubber latex and sounding balloons, applied in the field of natural rubber latex products, can solve the problems of low performance such as UV aging resistance and cold resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

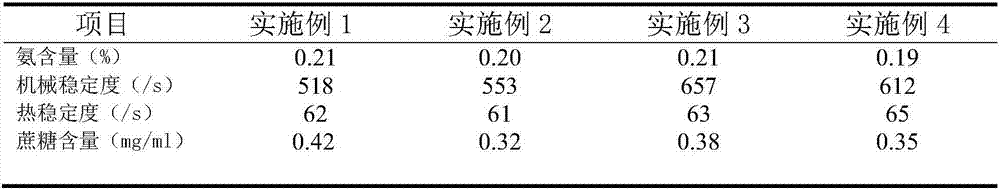

Examples

preparation example Construction

[0037] The preparation method of the natural rubber latex used in the air-sounding balloon of the present invention mixes the concentrated natural rubber latex of the above-mentioned content with the raw materials of lysozyme, ammonia and phospholipid.

[0038] The feeding method of mixing is: adding lysozyme to the concentrated natural rubber latex, and adding ammonia and phospholipid after waiting for 5-200 minutes.

[0039] Certainly also comprise the step of preparing above-mentioned concentrated natural rubber latex. The preparation of concentrated natural latex has been described previously.

[0040] What is not mentioned above is applicable to the prior art.

Embodiment 1

[0042] (a) Weigh 10 parts of calcium hydroxide and dissolve it in deionized water to prepare an aqueous solution with a mass fraction of 2%. spare;

[0043] (b) Weigh 2.4 parts of lysozyme and dissolve in deionized water to prepare an aqueous solution with a mass fraction of 10%. spare;

[0044] (c) Weigh 6 parts of water-soluble phospholipids and dissolve them in deionized water to prepare an aqueous solution with a mass fraction of 10%. spare;

[0045] Get 5000 parts of total solid mass fraction and be 25% fresh latex, add the calcium hydroxide aqueous solution described in (a), stir 1 hour, stand still and centrifuge for 6-8 hours, obtain the concentrated natural latex that total solid mass fraction is 60% . Then get 2000 parts of concentrated latex just centrifuged out, add the lysozyme aqueous solution described in (b), stop after 50-100 minutes, add the phospholipid aqueous solution described in (c), add 24 parts of ammoniacal liquor simultaneously (ammonia content i...

Embodiment 2

[0047] (a) Weigh 5 parts of calcium hydroxide and dissolve it in deionized water to prepare an aqueous solution with a mass fraction of 2%. spare;

[0048] (b) Weigh 2.4 parts of lysozyme and dissolve in deionized water to prepare an aqueous solution with a mass fraction of 10%. spare;

[0049] (c) Weigh 6 parts of water-soluble phospholipids and dissolve them in deionized water to prepare an aqueous solution with a mass fraction of 10%. spare;

[0050] Get 5000 parts of fresh latex with a total solid mass fraction of 25%, add the calcium hydroxide aqueous solution described in (a), stir for 1 hour, and leave it still for 6-8 hours to centrifuge to obtain a concentrated natural latex with a total solid mass fraction of 60%. latex. Then get 2000 parts of concentrated latex just centrifuged out, add the lysozyme aqueous solution described in (b), stop after 150-200 minutes, add the phospholipid aqueous solution described in (c), add 16 parts of ammoniacal liquor simultaneous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com