TPU film with automatic-repairing functions, and preparation method thereof

A film and raw material technology, applied in the field of biomaterials, can solve the problem that the self-healing function is not particularly prominent, and achieve the effects of good flexibility and wear resistance, broad application prospects and good comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

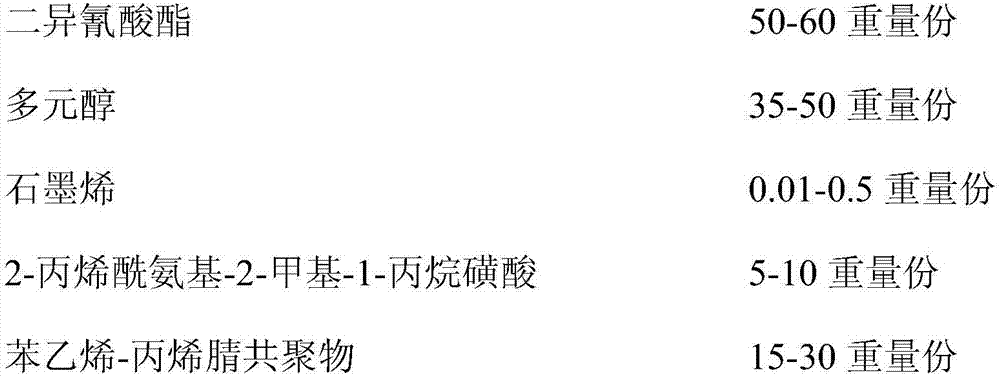

[0043] In this embodiment, the TPU film is prepared from the following raw material components:

[0044]

[0045]Wherein the diisocyanate is a mixture of toluene diisocyanate and 1,6-hexamethylene diisocyanate, the mass ratio of toluene diisocyanate and 1,6-hexamethylene diisocyanate is 1:4, and the polyol is polyester polyol and polyether polyol , wherein the mass ratio of polyester polyol and polyether polyol is 2:1, the number average molecular weight of the polyol is 1000, the number average molecular weight of styrene-acrylonitrile copolymer is 6000, and the chain extender is ethylene glycol, The catalyst is stannous octoate.

[0046] The preparation method is as follows:

[0047] (1) Add diisocyanate to A storage tank, polyols to B storage tank, chain extender and catalyst to C storage tank, stir at 400r / min at a speed of -0.2kPa vacuum dehydration at 70°C, pumping and injecting into the twin-screw extruder;

[0048] (2) Add 2-acrylamido-2-methyl-1-propanesulfonic ...

Embodiment 2

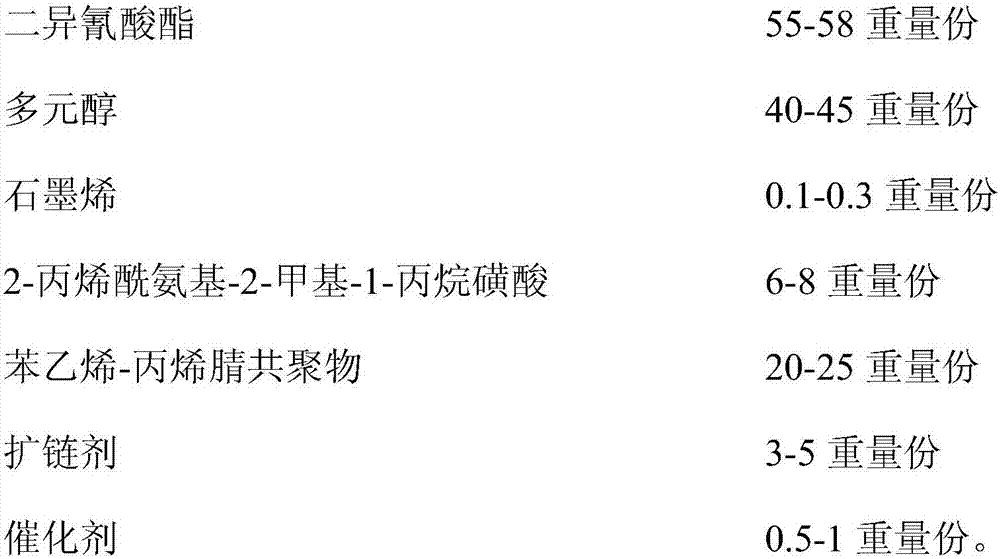

[0051] In this embodiment, the TPU film is prepared from the following raw material components:

[0052]

[0053] Wherein the diisocyanate is a mixture of toluene diisocyanate and 1,6-hexamethylene diisocyanate, the mass ratio of toluene diisocyanate and 1,6-hexamethylene diisocyanate is 1:5, and the polyol is polyester polyol and polyether polyol , wherein the mass ratio of polyester polyol and polyether polyol is 3:1. The number average molecular weight of the polyol is 2000, the number average molecular weight of styrene-acrylonitrile copolymer is 8000, and the chain extender is 1,3- Propylene glycol, the catalyst is dibutyltin dioctoate.

[0054] The preparation method is as follows:

[0055] (1) Add diisocyanate to A storage tank, polyol to B storage tank, chain extender and catalyst to C storage tank, and stir at 500r / min at a pressure of -0.3kPa vacuum dehydration at 60°C, pumping and injecting into the twin-screw extruder;

[0056] (2) Add 2-acrylamido-2-methyl-1...

Embodiment 3

[0059] In this embodiment, the TPU film is prepared from the following raw material components:

[0060]

[0061] Wherein the diisocyanate is a mixture of toluene diisocyanate and 1,6-hexamethylene diisocyanate, the mass ratio of toluene diisocyanate and 1,6-hexamethylene diisocyanate is 1:8, and the polyol is polyester polyol and polyether polyol , wherein the mass ratio of polyester polyol and polyether polyol is 1:1, the number average molecular weight of said polyol is 3000, the number average molecular weight of styrene-acrylonitrile copolymer is 5000, and the chain extender is 1.5 - Pentylene glycol, the catalyst is dibutyltin dilaurate.

[0062] The preparation method is as follows:

[0063] (1) Add diisocyanate to storage tank A, polyols to storage tank B, chain extender and catalyst to storage tank C, stir at 600r / min at a pressure of -0.1kPa vacuum dehydration at 80°C, pumping and injecting into the twin-screw extruder;

[0064] (2) Add 2-acrylamido-2-methyl-1-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com