Composite insulator defect non-destructive detection method

A composite insulator and non-destructive testing technology, applied in the field of electric power, can solve problems such as easy missed inspection, low universality, and wrong inspection, and achieve the effect of stable judgment, clear standards, and accurate defect identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

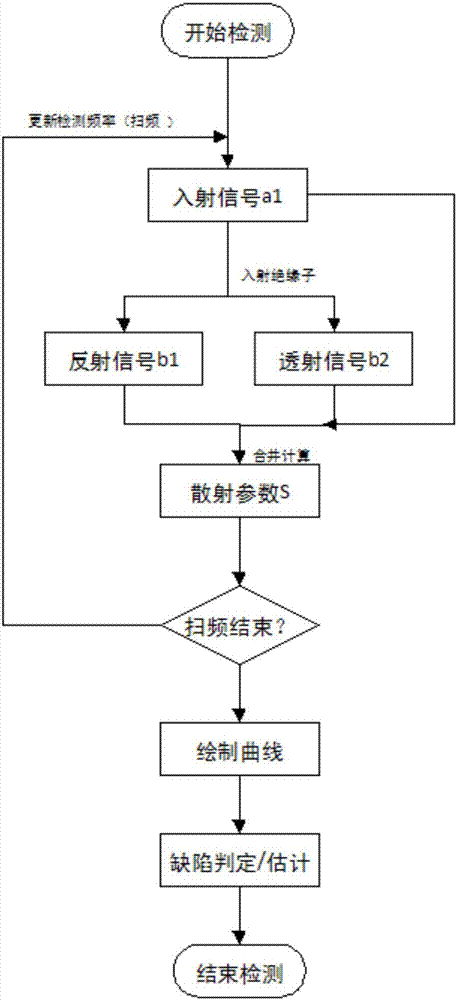

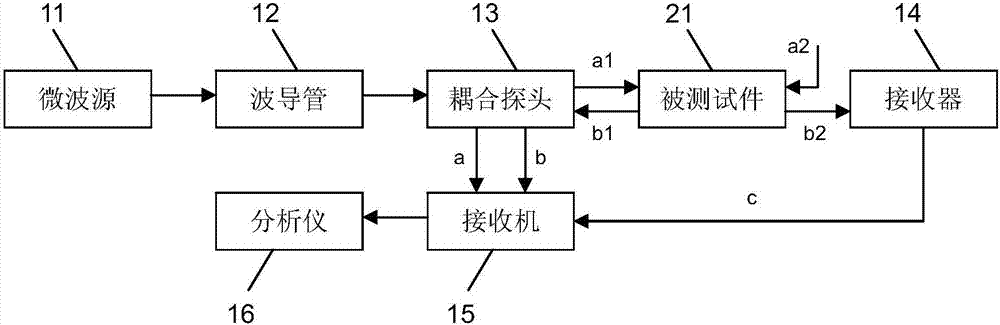

[0045] figure 2 It is a structural schematic diagram of an embodiment of the composite insulator defect non-destructive testing device proposed by the present invention. As shown in the figure, the composite insulator defect non-destructive testing device includes a microwave source 11, a waveguide 12, a coupling probe 13, a receiver 14, a receiving machine 15 and analyzer 16.

[0046] Wherein, the microwave source 11 provides microwave signals with variable frequency, the frequency range is 4-30GHz, the step interval is 0.1MHz, and the microwave bands are divided as follows: C-band 4-8GHz, X-band 8-12GHz, Ku-band 12-18GHz , K-band 18-27GHz, Ka-band 27-40GHz. The core band used by this device to realize the defect detection function is about 20-26GHz, so it is called "near K band". In actual use, any continuous frequency sweep band can be selected within this interval;

[0047] The waveguide 12 is a transmission device for microwave frequency sweep signals, and is used for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com