Packaging method for improving output concentration degree of LED (Light Emitting Diode) lamp beads

A technology of LED lamp beads and packaging methods, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of product brightness, poor color uniformity, and large particle size differences of phosphor particles, so as to reduce equipment requirements and operation difficulty. The effect of saving labor costs and being suitable for mass industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

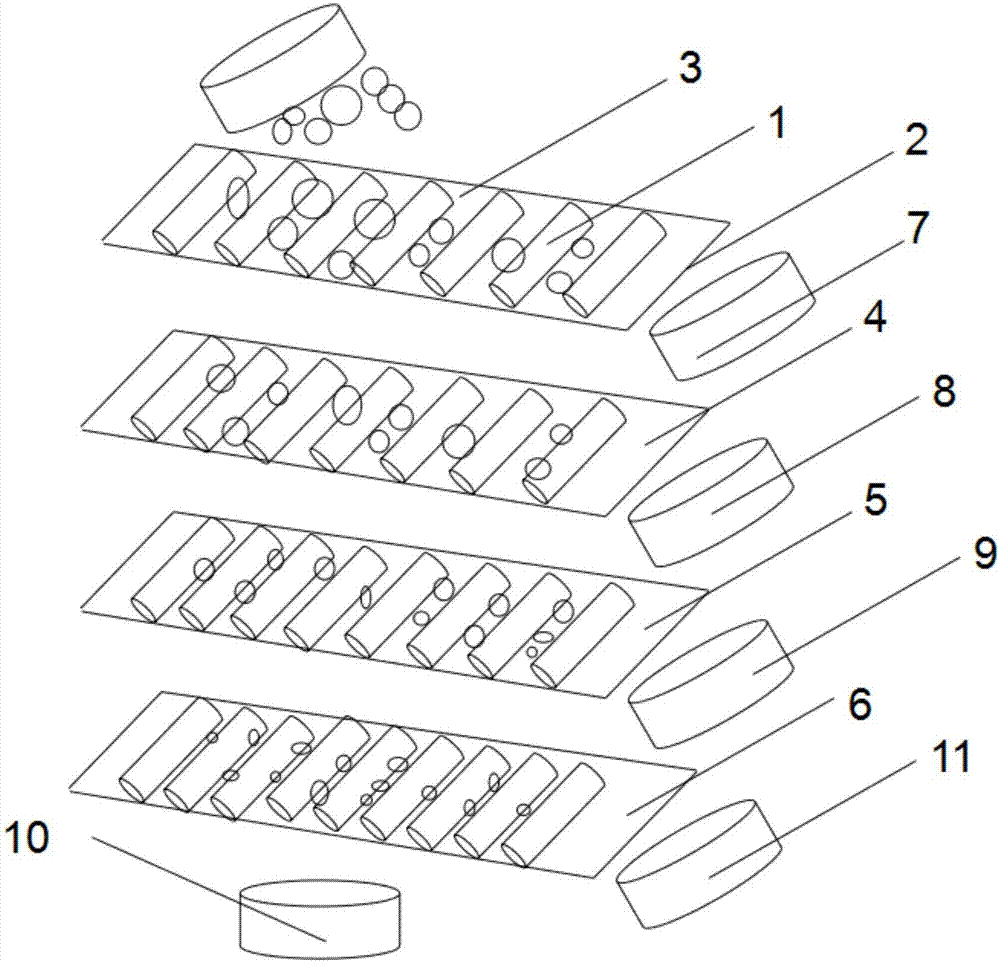

[0034] This embodiment provides a rolling type LED phosphor screening device, such as figure 1As shown, it includes at least two stages of rolling sieves. The rolling sieves of multiple stages are stacked one after another in the vertical direction. 1 Rotating drive mechanism, the distance between adjacent rollers 1 in each stage of rolling screen is 1-99 μm, the axial direction of rollers 1 is consistent, and along the direction from top to bottom, rollers 1 in each stage of rolling screen The spacing decreases step by step. The drive mechanism adopts a conventional drive motor, and the drive motor drives the roller 1 to rotate, and the roller 1 rolls to filter the fluorescent powder with a particle size smaller than the distance between the rollers 1 to the next-stage rolling sieve, and the rotating speed of the roller is 10 -600rpm / min, in this embodiment, the rotating speed of the roller is 10rpm / min. The rolling sieve can be set to two or more stages according to the pa...

Embodiment 2

[0044] This embodiment provides a rolling type LED phosphor screening device, the structure of which is basically the same as that of Embodiment 1, the difference is that the rolling sieve has three stages, from top to bottom are the first stage rolling sieve, the second stage The first-stage rolling screen and the third-stage rolling screen, the distance between two adjacent rollers in the first-stage rolling screen is 99 μm, the distance between two adjacent rollers in the second-stage rolling screen is 50 μm, and the third-stage rolling screen The distance between two adjacent rollers in the sieve is 30 μm.

[0045] This embodiment also provides a packaging method for improving the output concentration of LED lamp beads, including the following steps:

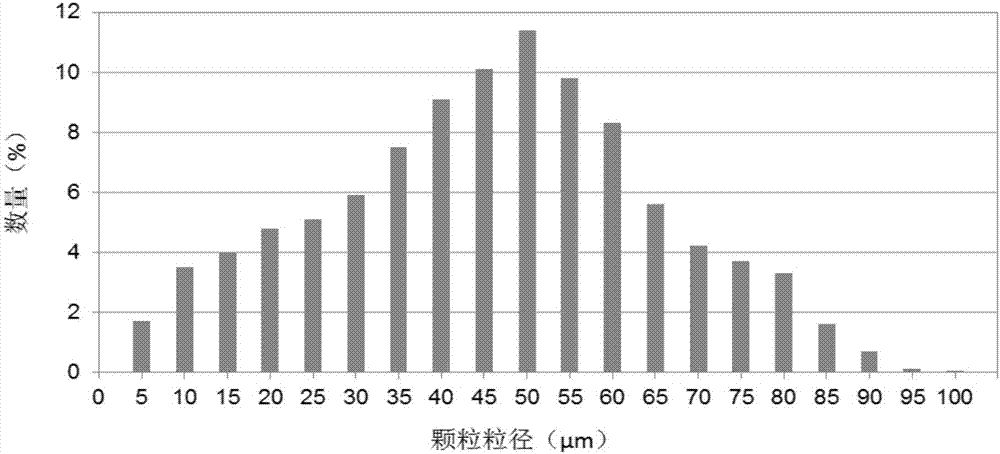

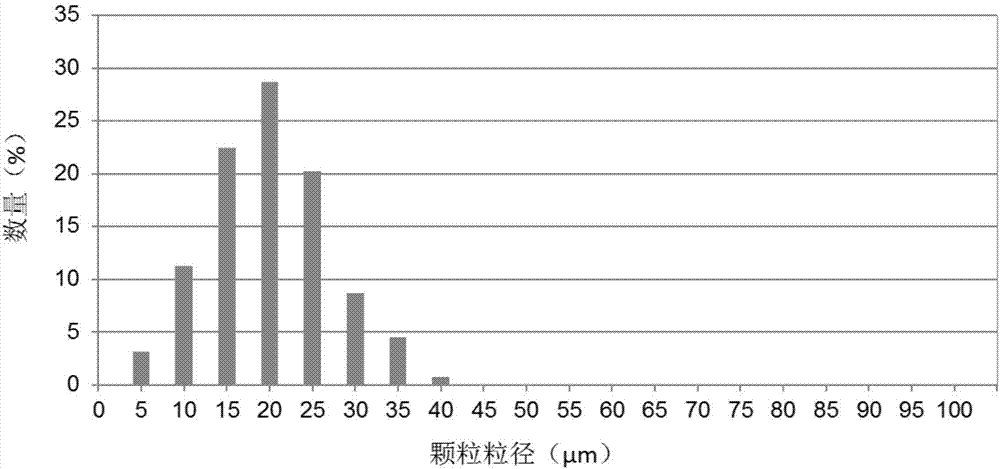

[0046] S1. Take the first fluorescent powder and place it on the rolling sieve at the top of the screening device, that is, the first-stage rolling sieve 3, start the drive motor, and the fluorescent powder whose particle si...

Embodiment 3

[0052] This embodiment provides a rolling type LED phosphor screening device, the structure of which is basically the same as that of Embodiment 1, the difference is that the rolling screen has five stages, from top to bottom are the first stage rolling screen, the second stage Stage rolling screen and third stage rolling screen, the distance between two adjacent rollers in the first stage rolling screen is 80 μm, the distance between two adjacent rollers in the second stage rolling screen is 45 μm, the third stage rolling The distance between two adjacent rollers in the sieve is 25 μm, the distance between two adjacent rollers in the fourth stage rolling screen is 7 μm, and the distance between two adjacent rollers in the fifth stage rolling screen is 2 μm.

[0053] This embodiment also provides a packaging method for improving the output concentration of LED lamp beads, including the following steps:

[0054] S1. Take the first fluorescent powder and place it on the rolling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com