Reinforced steel shot and preparation method thereof

A technology for strengthening steel and steel shot, used in manufacturing tools, metal processing equipment, abrasives, etc., can solve the problems of short service life, low fatigue strength, and large hardness deviation of strengthened steel shot, and achieve good surface shape consistency, The effect of high particle size consistency and small hardness deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Raw materials: the proportion of elements in the wire rod is composed of 0.8% carbon, 0.75% manganese, 0.2% silicon, 0.02% sulfur and 0.015% phosphorus, and the iron makes up the weight percentage to 100%.

[0063] Preparation:

[0064] 1. According to the above raw material requirements, the material is selected, and the wire is cold drawn for 3 times, and after pickling and two special vacuum annealing heat treatments, the semi-finished steel wire is obtained;

[0065] 2. Wire drawing: After 5-15 cold drawing, it is drawn into steel wires with different diameters between 0.3-2.0mm; the hardness range is HV590±30HV.

[0066] 3. Cutting: Use a wire cutter to cut the steel wire into cylindrical sections with the same diameter. The cut section is required to be flat, burr-free, and tail-free.

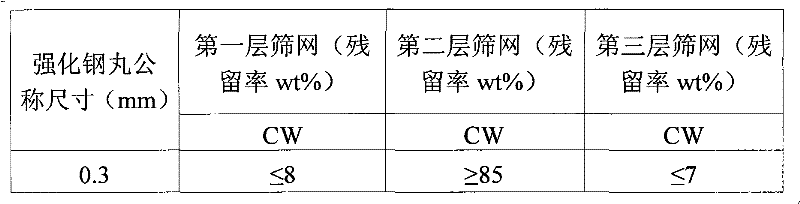

[0067] 4. Screening: Screening for different nominal sizes of steel shots. The nominal size of the sieve is 0.3-2.0 mm.

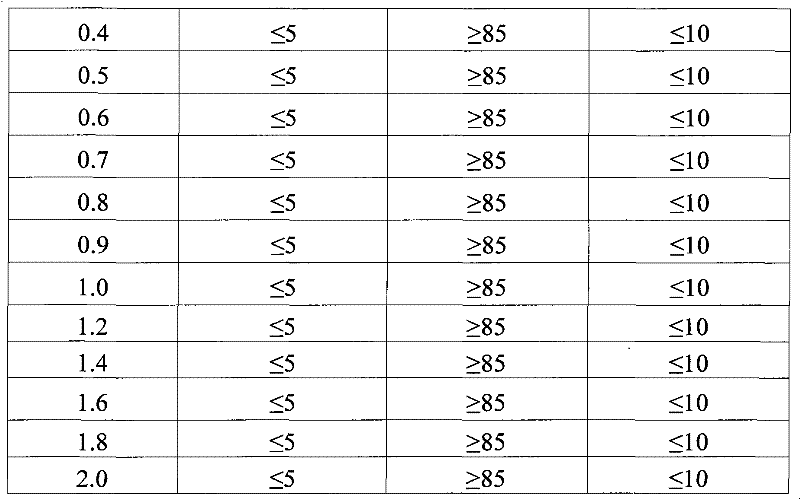

[0068] 5. Conduct hardness, density and fatigue life te...

Embodiment 2

[0080] Raw materials: the proportion of elements in the wire rod is composed of 0.85% carbon, 0.8% manganese, 0.25% silicon, 0.015% sulfur and 0.02% phosphorus, and the iron makes up the weight percentage to 100%.

[0081] Preparation:

[0082] 1. Select materials according to the above raw material requirements, cold draw the wire rod for 5 times, and then go through weak sulfuric acid dipping and vacuum isothermal annealing heat treatment twice to obtain semi-finished steel wire;

[0083] 2. Wire drawing: After 5-15 cold drawing, it is drawn into steel wires with different diameters between 0.3-2.0mm; the hardness range is HV590±30HV.

[0084] 3. Cutting: Use a wire cutter to cut the steel wire into cylindrical sections with the same diameter. The cut section is required to be flat, burr-free, and tail-free.

[0085] 4. Screening after surface rounding and strengthening: Screening for different nominal sizes of steel shots. The nominal size of the sieve is 0.3-2.0 mm.

[...

Embodiment 3

[0097] Raw materials: the proportion of elements in the wire rod is composed of 0.82% carbon, 0.65% manganese, 0.3% silicon, 0.01% sulfur and 0.01% phosphorus by weight percentage, and the iron makes up the weight percentage to 100%.

[0098] The preparation method is the same as in Example 2.

[0099] Thereby four reinforced steel shots of CW, G1, G2 and G3 shapes were obtained. The component weight ratio of the reinforced steel shot is: 0.82% carbon, 0.65% manganese, 0.3% silicon, 0.01% sulfur and 0.01% phosphorus, and iron makes up the weight percentage to 100%.

[0100] The size distribution ratio data of strengthening steel shot is the same as Table 6, and the final passing rate of steel shot is: CW≤0.6%, G1≤0.5%, G2≤0.5%, G3≤0.5%. The standard nominal size range of reinforced steel shot: 0.30-2.0mm. The hardness grade and hardness range of reinforced steel shots are the same as Table 7, and the performance data are shown in Table 9.

[0101] Table 9

[0102]

[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com