Model-free power control method for PFC (Power Factor Correction) AC/DC converter

A technology of power control and converter, which is applied in the direction of converting AC power input to DC power output, output power conversion device, high-efficiency power electronic conversion, etc. Problems such as high-efficiency operation of DC converters and limited service life of electrolytic capacitors can achieve the effects of improving dynamic performance and steady-state performance, increasing service life, and improving dynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

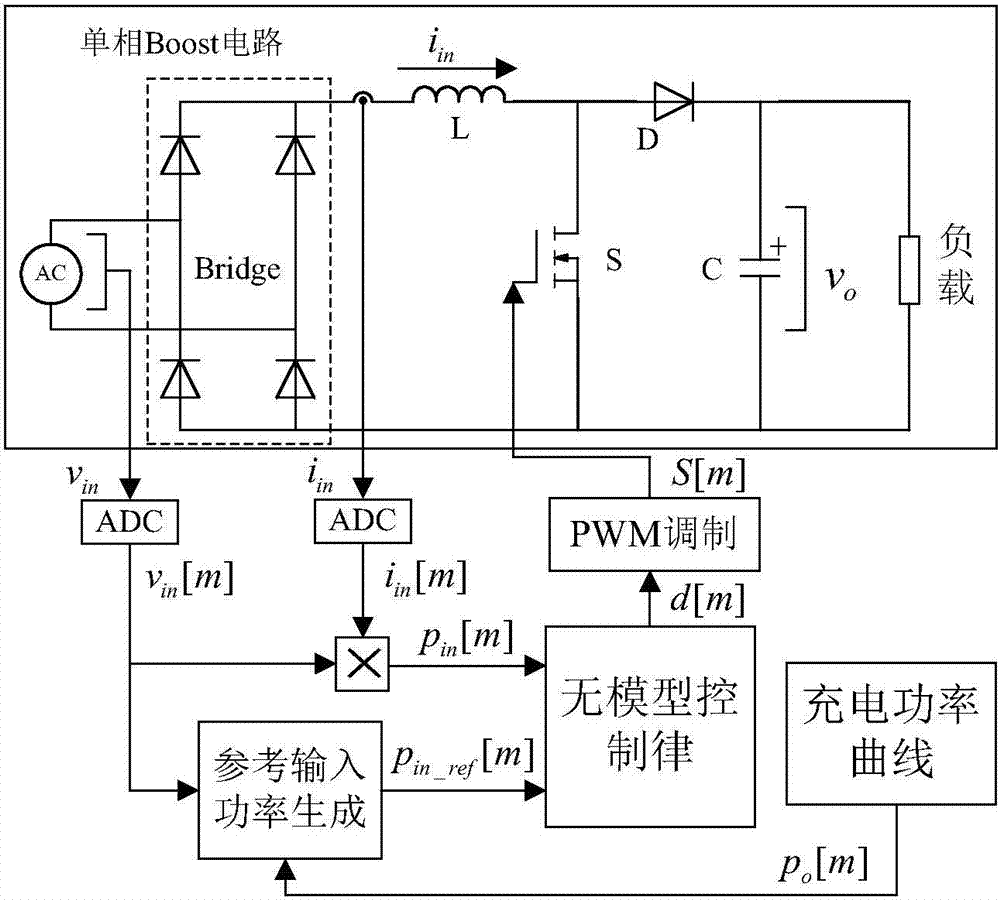

[0053] In this embodiment, the model-free power control method of the PFC AC / DC converter is applied to an electric vehicle on-board charger, figure 1 The PFC AC / DC converter system shown includes a single-phase Boost circuit, AC input voltage v in Detection conditioning circuit, inductor current i in Detection and conditioning circuit, reference input power generation module, model-free control law module, charging power curve module and PWM modulation module, in which the single-phase Boost circuit includes AC power supply AC, diode uncontrolled rectifier bridge Bridge, inductor L, power switching device S, Diode D, output DC side capacitor C and load; for the convenience of expression, figure 1 The indiscriminate unity of the AC input voltage detection and conditioning circuit and the inductor current detection and conditioning circuit is represented by the detection and conditioning circuit ADC.

[0054] The model-free power control method of the PFC AC / DC converter in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com