Hot melt adhesive composition comprising at least one particular aldehyde scavenger

A technology for hot melt adhesives and compositions, applied in the field of volatile organic compounds and hot melt adhesive compositions, can solve problems such as filter clogging, achieve good bond strength, avoid sedimentation and/or filter Blocking problems, effect of good adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] According to a specific embodiment of the present invention, the hot melt adhesive composition is HMPSA, which comprises:

[0052] A- 15% to 35% by weight of at least one thermoplastic polymer selected from polyolefins, styrene block copolymers (SBC), ethylene-vinyl acetate (EVA) and mixtures thereof;

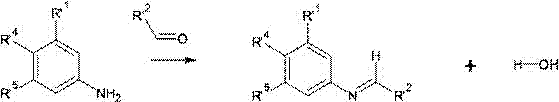

[0053] B - 30% to 60% by weight of at least one tackifying resin;

[0054] C - 0.01% to 1% by weight, preferably 0.09% to 0.5% by weight, of at least one aldehyde scavenger having a molar weight of less than 500 g / mol and a melting point of less than 170°C, and in its structure An aromatic ring comprising an aromatic ring bonded directly or indirectly to at least one amine capping group as defined below, and preferably selected from 2-aminobenzamide, 3-aminobenzamide, 1,8-diaminonaphthalene, 2-amino Benzenesulfonamide, benzene-1,2-diamine and mixtures thereof;

[0055] D - 10% to 30% by weight of at least one plasticizer selected from naphthenic oils, paraffinic oils a...

Embodiment

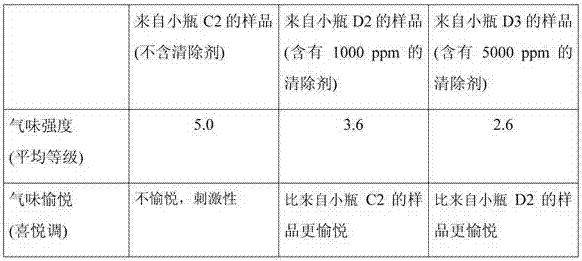

[0273] Effect of aldehyde scavengers on two pure aldehyde volatiles:

[0274] Preparation of volatile aldehydes in the gas phase:

[0275] Prepare four vials A1, A2, A3 and A4 as follows:

[0276] Introduce 15 μL of butyraldehyde (liquid at 23 °C, boiling point (bp) = 74.8 °C) with a syringe into 20 mL vial A1 sealed with an airtight rubber cap, and then fill the vial with nitrogen. In the same manner, a second vial A2 was prepared.

[0277] Introduce 15 μL of benzaldehyde (liquid at 23 °C, bp = 178.1 °C) with a syringe into a second 20 mL vial A3 sealed with an airtight rubber cap, which is then filled with nitrogen. In the same manner, a second vial A4 was prepared.

[0278] The four vials A1 , A2, A3 and A4 were left standing at 23°C for at least 12 hours to allow the redistribution of the gas phase of the volatile aldehyde to equilibrate evenly in the vials.

[0279] Preparation of Vials A5 and A6 Containing Volatile Aldehydes and Without Aldehyde Scavenger C (Refer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com