Cement paste system for well cementation

A technology of cement slurry and oil well cement, which is applied in the field of ultra-deep well cementing and deep well, can solve the problems of poor slurry stability, poor shear resistance and compression resistance of floating beads, cracking, etc., and achieve enhanced retarding performance 、To overcome the super-retarding effect of low-temperature cement column

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Preparation of cement slurry systems with different densities:

[0025] The preparation density is 1.3g / cm 3 The cement slurry system, this experiment is named No. 1:

[0026] Take 100 parts of G grade oil well cement, 45 parts of micro silicon, 50 parts of lightening material, 3.5 parts of fluid loss reducer, 0.8 part of dispersant, 0.9 part of retarder, 3 parts of early strength agent, 1.5 parts of defoamer, 250 parts Water, prepare cement slurry according to API specification Spe-10A, standby;

[0027] The preparation density is 1.4g / cm 3 The cement slurry system, this experiment is named No. 2:

[0028] Take 100 parts of G-grade oil well cement, 25 parts of micro-silicon, 35 parts of lightening material, 3 parts of fluid loss reducer, 0.5 part of dispersant, 1.2 parts of retarder, 1.5 parts of early strength agent, 1 part of defoamer, 175 parts Water, prepare cement slurry according to API specification Spe-10A, standby;

[0029] The preparation density is 1.5g...

Embodiment 2

[0032] Evaluation of cement slurry properties

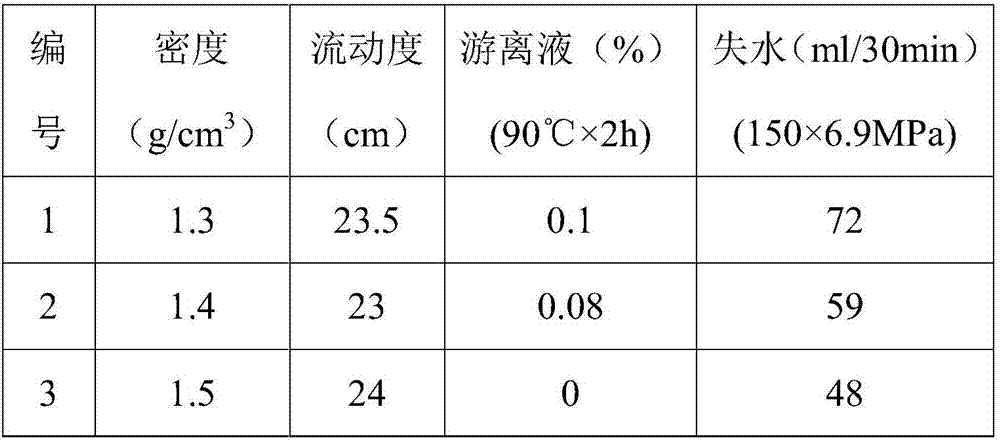

[0033] Taking Example 1 as the test object, the basic performance test and evaluation of cement slurry was carried out according to GB / T 19139-2012 "Test Methods for Oil Well Cement". The test results are shown in Table 1.

[0034] Table 1 Test results of basic performance of cement slurry under different densities

[0035]

[0036] As can be seen from Table 1, the fluidity of the cement slurry prepared with the cement slurry formulation of the invention is between 21 and 24 cm, indicating that the pumpability of the cement slurry is good. The free water content is less than 0.1%, which shows that the cement slurry prepared by the present invention has good stability and takes into account the stability and rheological properties of the whole system. In addition, the water loss of the whole system is within 75mL, so it can effectively control the water loss during the construction process, thereby avoiding the change of cemen...

Embodiment 3

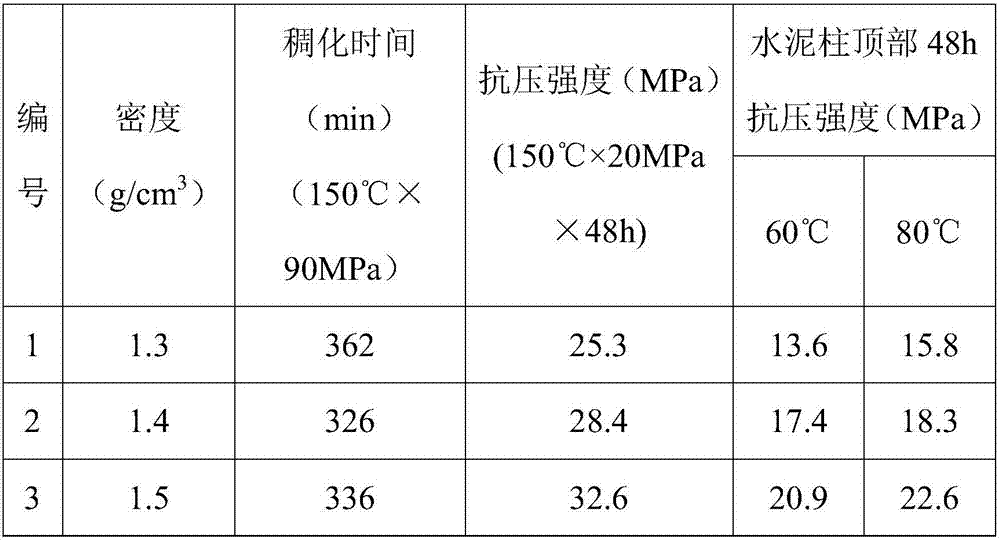

[0038] Evaluation of Thickening Time and Compressive Strength of Cement Slurry

[0039] Taking Example 1 as an example, according to GB19139-2003, the compressive strength of the top of the cement column is tested by the high-temperature dynamic prefabrication method, that is, the cement slurry is mixed and loaded into a high-temperature and high-pressure thickening instrument, and enters the high-temperature constant temperature section according to the thickening test plan. Lower it to the resting temperature at the top, remove the thickener pulp cup, remove the oil, and then make a mold and place it at the top temperature to maintain it until it ages. The test results are shown in Table 2:

[0040] Table 2 Thickening time and compressive strength test results of cement slurries with different densities

[0041]

[0042] It can be seen from Table 2 that the thickening time of the cement slurry system prepared by the invention is greater than 300 minutes at a high tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com