Well cementation retarder

A technology of retarder and cementing, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of insufficient retarder performance, large temperature difference, high temperature resistance, low sensitivity to temperature and dosage, etc. Achieve the effect of overcoming the ultra-retardation of the low-temperature cement column, reducing the adsorption, and enhancing the retardation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

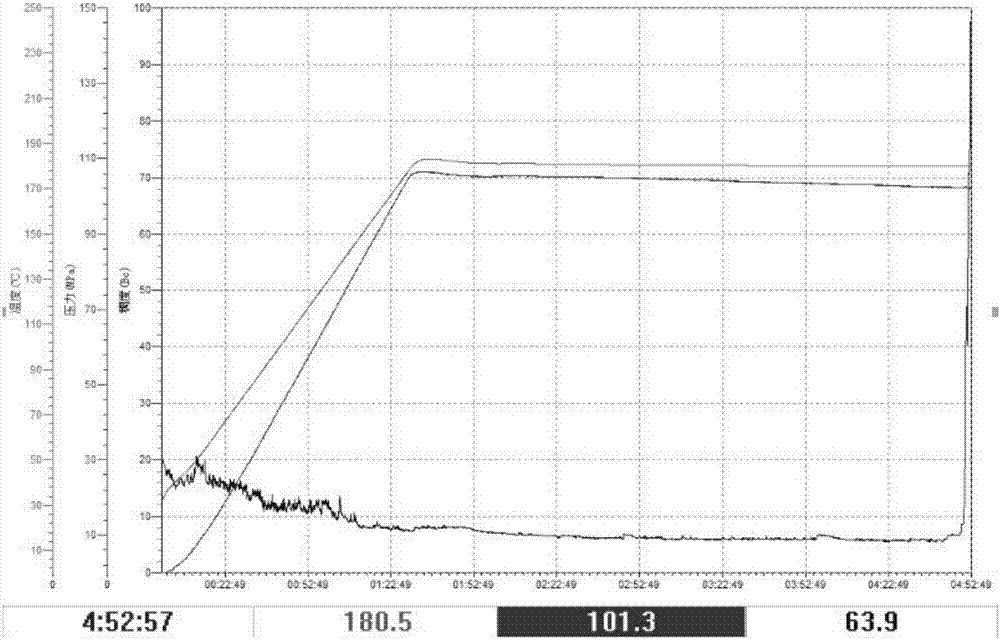

Embodiment 1

[0026] Preparation of quaternary composite ionic copolymers by aqueous solution radical polymerization:

[0027] 1) preparing itaconic acid, sodium p-styrenesulfonate, and an aqueous solution of acryloyloxyethyltrimethylammonium chloride;

[0028] 2) Using a constant pressure dropping funnel, add the aqueous solution of methallyl polyoxyethylene ether and ammonium persulfate dropwise to the aqueous solution described in step 1), and react at 60° C. for 3 hours;

[0029] 3) drying and pulverizing the product obtained in step 2) to obtain the quaternary composite ionic copolymer.

[0030] The molar ratio of itaconic acid, sodium p-styrenesulfonate, acryloyloxyethyltrimethylammonium chloride and methallyl polyoxyethylene ether is 25:60:15:0.05.

[0031] Obtain the required quaternary composite ionic copolymer of the present embodiment.

[0032] The tetrapolymer of 9g, 0.6g sodium gluconate and 0.3g hydroxyethylidene diphosphoric acid are mixed to obtain the retarder required in...

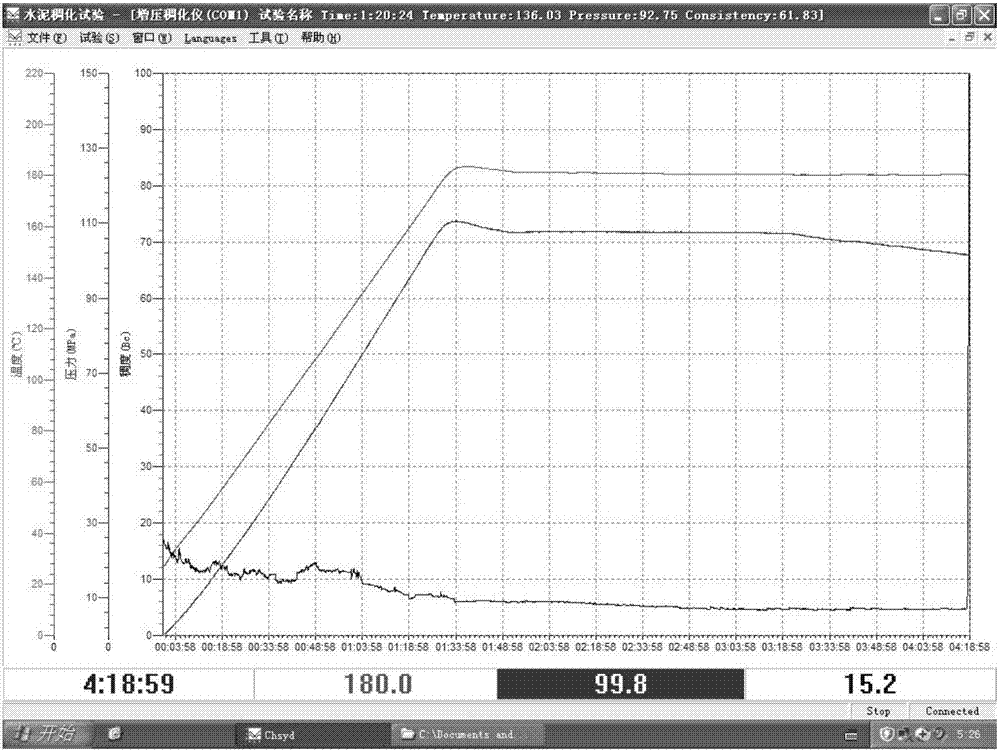

Embodiment 2

[0045] Preparation of quaternary composite ionic copolymers by aqueous solution radical polymerization:

[0046] 1) preparing itaconic acid, sodium p-styrenesulfonate, and an aqueous solution of acryloyloxyethyltrimethylammonium chloride;

[0047] 2) Add the aqueous solution of methallyl polyoxyethylene ether and ammonium persulfate dropwise to the aqueous solution described in step 1) using a constant pressure dropping funnel, and react at 60° C. for 4 hours;

[0048] 3) drying and pulverizing the product obtained in step 2) to obtain the quaternary composite ionic copolymer.

[0049] The molar ratio of itaconic acid, sodium p-styrenesulfonate, acryloyloxyethyltrimethylammonium chloride and methallyl polyoxyethylene ether is 25:60:15:0.05.

[0050] Obtain the required quaternary composite ionic copolymer of the present embodiment.

[0051] 7.5g of the tetrapolymer, 0.15g of sodium gluconate and 0.2g of hydroxyethylidene diphosphoric acid were mixed to obtain the retarder re...

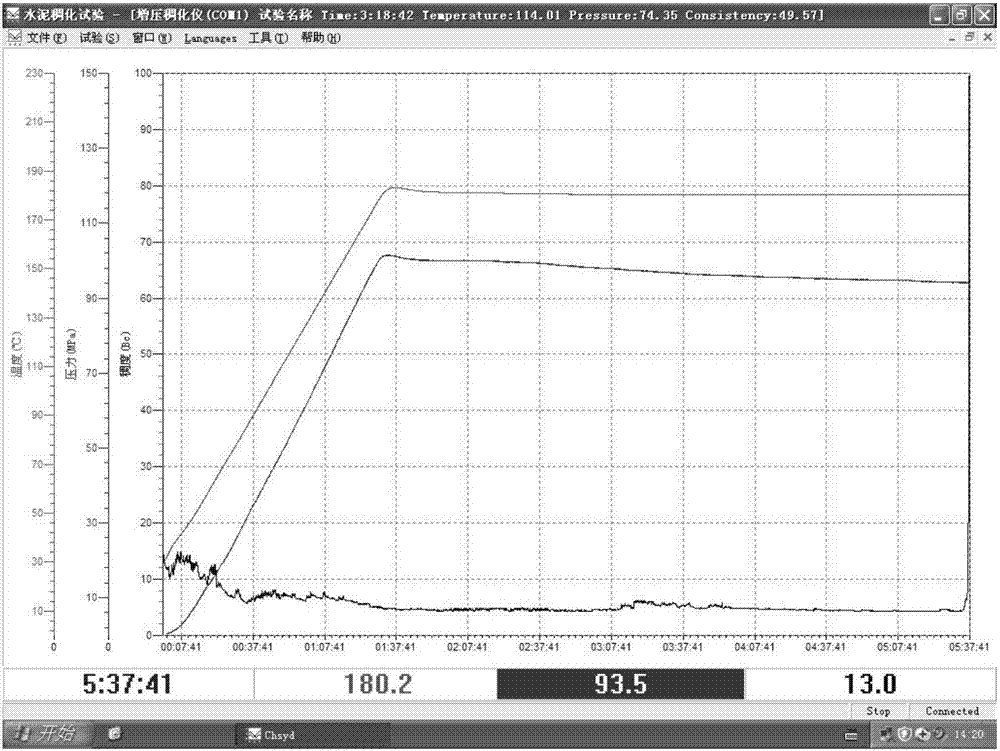

Embodiment 3

[0064] Preparation of quaternary composite ionic copolymers by aqueous solution radical polymerization:

[0065] 1) preparing itaconic acid, sodium p-styrenesulfonate, and an aqueous solution of acryloyloxyethyltrimethylammonium chloride;

[0066] 2) Using a constant pressure dropping funnel, add the aqueous solution of methallyl polyoxyethylene ether and ammonium persulfate dropwise to the aqueous solution described in step 1), and react at 60° C. for 5 hours;

[0067] 3) drying and pulverizing the product obtained in step 2) to obtain the quaternary composite ionic copolymer.

[0068] The molar ratio of itaconic acid, sodium p-styrenesulfonate, acryloyloxyethyltrimethylammonium chloride and methallyl polyoxyethylene ether is 25:60:15:0.05.

[0069] Obtain the required quaternary composite ionic copolymer of the present embodiment.

[0070] 4.8g of said tetrapolymer, 1.8g of sodium gluconate and 1.5g of hydroxyethylidene diphosphoric acid were mixed to obtain the retarder r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com