Construction method and structure for preventing differential settlement of concrete facing dam plinth

A technology for face slab dams and toe boards, which is applied in basic structural engineering, soil protection, construction, etc., can solve problems such as large differences in deformation, pulling cracks, large dislocation deformation of connecting plates and toe boards, etc. The effect of low cost and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

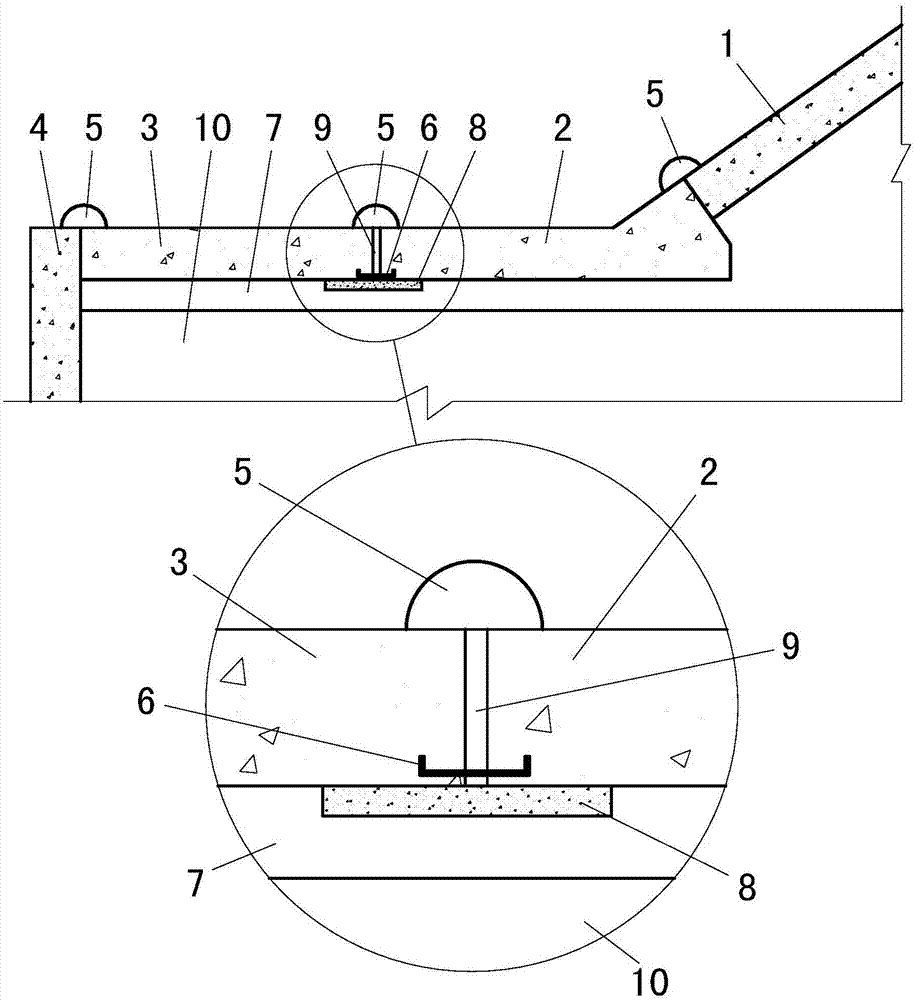

[0033] The structure for preventing uneven settlement of the face dam toe slab based on the covering layer in this example includes: concrete face 1, concrete toe slab 2, concrete connecting plate 3, cut-off wall 4, top layer flexible water stop 5, copper sheet water stop 6 , Foundation leveling layer 7, backing plate 8, structural joint 9, covering layer foundation 10.

[0034] Among them, the base leveling layer 7 is the base surface treatment of the anti-seepage structure, which is mainly backfilled with cushion material and rolled into the chamber, and can also be backfilled with rockfill concrete, concrete, etc., with a thickness of not less than 1.5m; 2 and the support structure with uneven deformation of the concrete connecting plate 7 can generally be prefabricated or cast-in-place concrete.

[0035] The specific implementation steps are as follows:

[0036] Step 1, first carry out necessary tamping or other processing to the covering layer foundation 10, and start th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com