Sponge city construction road rainwater processing system

A sponge city and treatment system technology, applied in the field of rainwater treatment system for sponge city construction roads, can solve the problems of difficult rainwater drainage, water accumulation in green belts, etc., and achieve the effect of long action time, good effect and improved utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

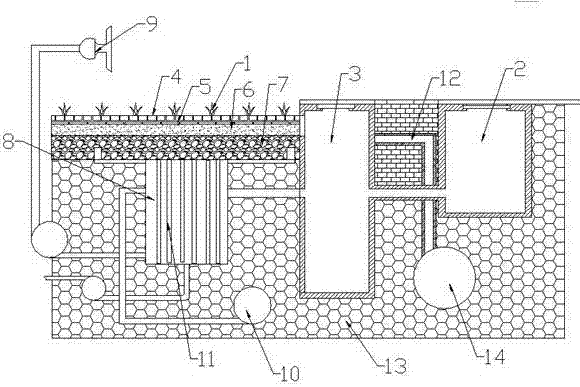

[0014] Sponge city construction road rainwater treatment system, including green belt 1, seepage storage well 2, water storage well 3, the top of seepage storage well 2 and water storage well 3 are covered, green belt 1 is concave, green belt 1 It includes the upper planting part and the lower purification part, wherein the planting part consists of a partition net 4, a planting soil layer 5, a sandstone layer 6, and a biochar layer 7 arranged in sequence from top to bottom, wherein the partition net 4 is made of bamboo fiber, Carbon fiber and superabsorbent fiber are made of mixed fibers according to the weight ratio of 1:3:1, and a graphene photocatalytic net is laid under the partition; the purification part includes a purification box 8, and the outlet side of the purification box 8 is passed through a delivery pipe and a delivery pump. The upper nozzle 9 on the ground, the nearby residential water tank, and the underground long-distance delivery pipe 10; the overall settin...

Embodiment 2

[0018] The sponge city construction road rainwater treatment system of this embodiment is the same as that of Embodiment 1 except for the following differences: the planting soil layer 5 is mixed with the following raw materials in parts by weight: 8 parts of lemongrass powder, 20 parts of straw powder, 25 parts of yellow loam, 10 parts of fine sand, 5 parts of humus, 1 part of capsule microorganism, 1 part of capillary, 3 parts of tea meal, 3 parts of adhesive; the amount of Bacillus, Saccharomyces cerevisiae, and nitrifying bacteria in capsule microorganisms The ratio is 2:5:3. The adhesive is made by mixing gum arabic, silicone, polyisobutylene, and silicate in a weight ratio of 3:1:3:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com