TPU thin-walled hose for oxygenic aeration and opening mode

An oxygen-filled aeration and thin-walled technology, applied in water aeration, aerobic process treatment, chemical instruments and methods, etc., can solve the problems of low oxygen transfer efficiency, large resistance loss, uneven air distribution, etc. The output speed is uniform and slow, the ventilation volume is increased, and the number of bubbles is large

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to better understand the technical solution of the present invention, it will be further described below in conjunction with specific embodiments:

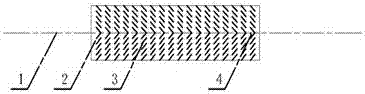

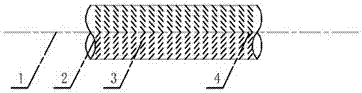

[0025] like figure 1 As shown, the implementation of the present invention provides a TPU thin-walled hose for oxygenated aeration. Its main material is TPU polyurethane, adding a variety of additives to increase strength, elasticity and toughness, made by extrusion equipment such as figure 1 As shown in the thin-walled hose, the thickness of the pipe wall 2 is 0.1-1mm. In the non-oxygenated state, the openings 3 on the pipe wall are evenly made on the pipe wall 2 along the direction of the pipe centerline 1. The number of openings 3 on the TPU thin-walled hose per meter is 2000~8000, and the pipe wall 2 The shape of the upper opening 3 is long strip, the width is 0.05~0.25mm, and the length is 0.5~2.5mm. The tube centerline 1 is symmetrical on both sides. Under the condition of moderate stretching, the effect a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com