A kind of preparation method of hexachloro-1,3-butadiene

A technology of butadiene and trichloroethylene, which is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of reduced flammability, no direct preparation, etc., and achieves easy operation, high atom utilization, The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

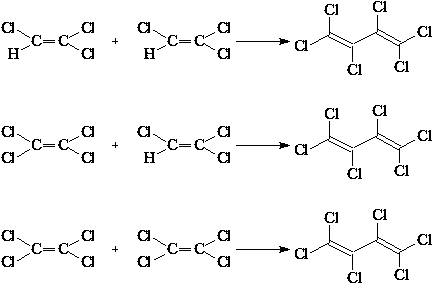

[0017] A preparation method of hexachloro-1,3-butadiene, the reaction equation is as follows:

[0018]

Embodiment 1

[0020] Trichlorethylene: tetrachlorethylene weighed 20.8g trichlorethylene and 79g tetrachlorethylene in a hydrothermal kettle with a molar ratio of 1:3, and added 20g of anhydrous aluminum trichloride with a mass fraction of 20%. After reacting at 80°C for 8 hours, the conversion rate of trichlorethylene was 63%, and the selectivity of hexachloro-1,3-butadiene was 32%.

Embodiment 2

[0022] Trichlorethylene: tetrachlorethylene weighed 13.8g trichlorethylene and 87g tetrachlorethylene in a hydrothermal kettle with a molar ratio of 1:5, and added 5.04g of anhydrous aluminum trichloride with a mass fraction of 5%. The reaction was carried out at 120°C for 4 hours, the conversion rate of trichlorethylene was 72%, and the selectivity of hexachloro-1,3-butadiene was 27%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com