Hydrogenated styrene-conjugated diene copolymer and its catalyst removal method and preparation method

A technology for conjugated diene and hydrogenated styrene, which is applied in the field of hydrogenated styrene-conjugated diene copolymer and its catalyst removal, which can solve difficult nickel content, complex catalyst removal methods, and reduce to a lower level, etc. problem, to achieve the effect of simple removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention also provides a method for preparing a hydrogenated styrene-conjugated diene copolymer, the method comprising: hydrogenating the styrene-conjugated diene copolymer with hydrogen in the presence of a nickel-based hydrogenation catalyst, Obtaining the hydrogenated styrene-conjugated diene copolymer glue solution, the method further includes removing the catalyst from the obtained hydrogenated styrene-conjugated diene copolymer glue solution by using the above catalyst removal method.

[0043] The present invention also provides the hydrogenated styrene-conjugated diene copolymer prepared by the method for preparing the hydrogenated styrene-conjugated diene copolymer.

[0044] The hydrogenated styrene-conjugated diene copolymer with low nickel content can be obtained by adopting the preparation method of the present invention. Preferably, the nickel content in the hydrogenated styrene-conjugated diene copolymer provided by the present invention is belo...

Embodiment 1

[0052] This example is used to illustrate the catalyst removal method of the present invention and the preparation of hydrogenated polystyrene-butadiene copolymer.

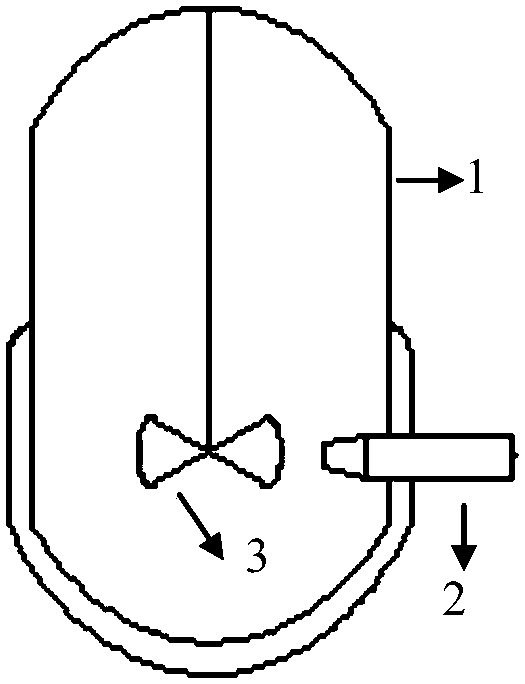

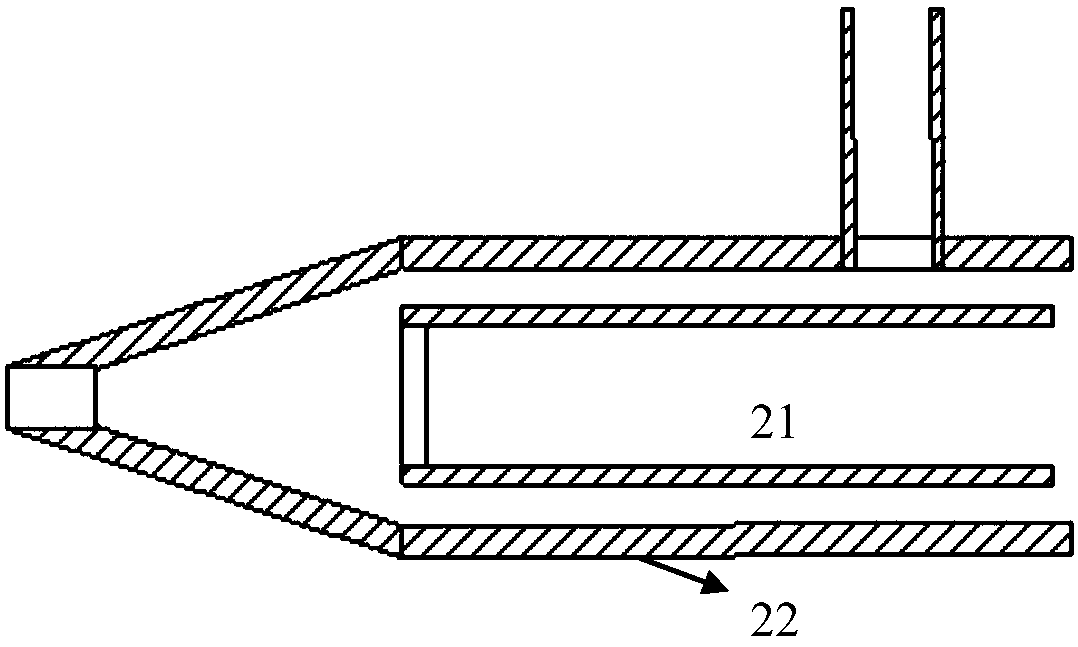

[0053] use figure 1 with 2 The stirring device shown is carried out, under the agitation of the end line speed of the blade of the stirring paddle 3 being 55m / min, the above-mentioned hydrogenated polystyrene-butadiene copolymer glue solution is sprayed into by the inner spray pipe 21, and water is sprayed from the outside Pipe 22 sprays in, and hydrogenated polystyrene-butadiene copolymer glue liquid is sprayed out by nozzle of nozzle pipe 2 while contacting with citric acid aqueous solution (citric acid content is 1 weight %) at the outlet of nozzle pipe 21. Among them, the injection linear velocity of the hydrogenated polystyrene-butadiene copolymer glue is 15m / min, the volume flow rate is 0.03L / min, and the temperature is 60°C; the injection linear velocity of the citric acid aqueous solution is 150m / min, and...

Embodiment 2

[0056] This example is used to illustrate the catalyst removal method of the present invention and the preparation of hydrogenated polystyrene-butadiene copolymer.

[0057] According to the method described in Example 1, the difference is that a 2% by weight aqueous solution of citric acid at 60° C. is used as an aqueous extractant to spray from the outer nozzle 22 to obtain a hydrogenated polystyrene-butadiene copolymer The nickel content in the dry glue is 10ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volumetric flow rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com