Low-heat-conductivity heat-insulation test fluid, and preparation method and application thereof

A technology of low thermal conductivity and testing fluid, applied in chemical instruments and methods, measurement, earthwork drilling and mining, etc., can solve the problems of large limitations, high cost, unfavorable operation, etc., and achieve the effect of strong inhibition and excellent anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

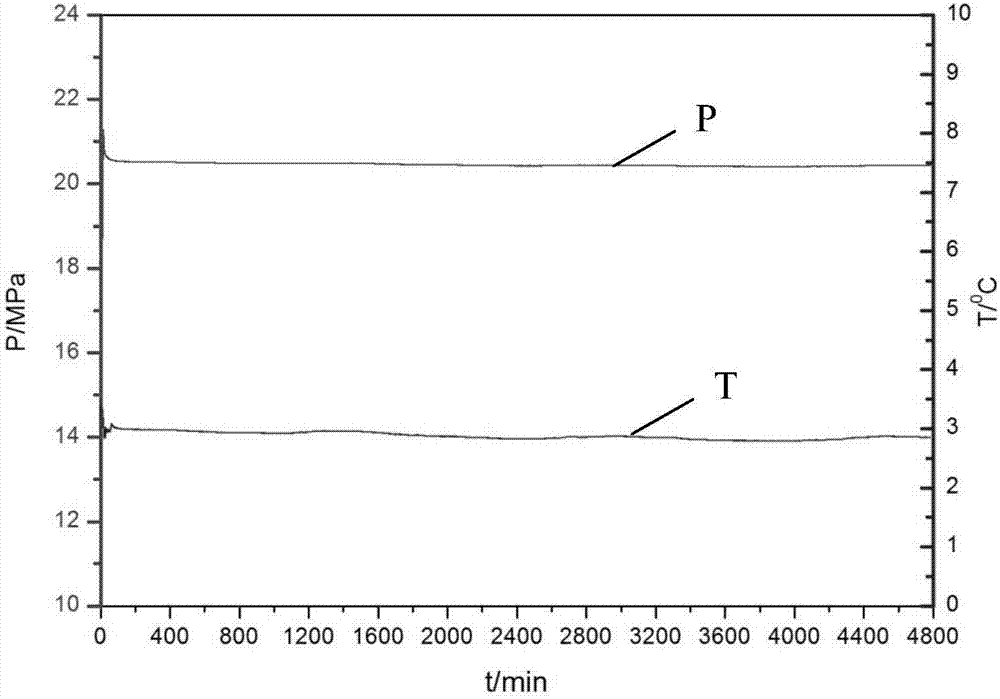

Image

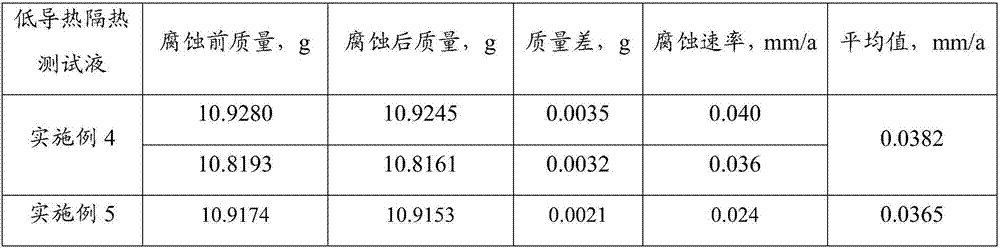

Examples

Embodiment 1

[0038] Use calcium chloride as a weighting agent, with a configuration density of 1.3g / cm 3 Low thermal conductivity and heat insulation test fluid: Measure 160mL fresh water and 240mL low thermal conductivity base fluid in a slurry cup with a graduated cylinder, and add 2.4g anti-high temperature deoxidizer and 0.95g in turn while stirring at a speed of 10,000r / min. Membrane corrosion inhibitor, 9.5mL passivation corrosion inhibitor, stir at high speed for 20 minutes, add 200g calcium chloride, and stir at high speed for 40 minutes.

Embodiment 2

[0040] Using calcium bromide as a weighting agent, the configuration density is 1.4g / cm 3 Low thermal conductivity and heat insulation test fluid: Measure 160mL of fresh water and 240mL of low thermal conductivity base fluid in a slurry cup with a graduated cylinder. Add 2.2g of anti-high temperature deoxidizer and 0.9g in turn while stirring at a speed of 10,000r / min. Membrane corrosion inhibitor, 9mL passivation corrosion inhibitor, stir at high speed for 20 minutes, add 200g calcium bromide, and stir at high speed for 40 minutes.

Embodiment 3

[0042] Calcium chloride and calcium bromide are used as weighting agents at the same time, the configuration density is 1.5g / cm 3 Low thermal conductivity and heat insulation test fluid: Measure 160mL fresh water and 240mL low thermal conductivity base fluid in a slurry cup with a graduated cylinder, and add 2.4g anti-high temperature deoxidizer and 1.0g in turn while stirring at a speed of 10,000r / min. Film corrosion inhibitor, 14.7mL passivation corrosion inhibitor, high-speed stirring for 20min, add 180g calcium chloride, high-speed stirring for 20min, then add 160g calcium bromide, high-speed stirring for 40min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com