Acidification blocking remover applicable to deep volcanic gas reservoir and construction method thereof

A volcanic rock and deep layer technology, which is applied in the field of acidizing plugging remover and its construction in deep volcanic rock gas reservoirs, can solve the problems of ineffective plugging removal, limited effect, and high risk of sand stuck pipe strings, achieve uniform acid distribution, avoid Effect of secondary damage and increase of construction net pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] An acidizing plug-removing agent for deep volcanic rock gas reservoirs, comprising the following components by weight:

[0053] Agent A: 15% Hcl + 2% high temperature corrosion inhibitor + 2.5% active thickener + 1% clay stabilizer + 0.5% iron ion stabilizer + 3% co-surfactant + water.

[0054] Agent B: 15% Hcl + 3% co-surfactant + 2% high temperature corrosion inhibitor + 2.5% active thickener + 3% fluorine salt + 3% retarded acid + 1% clay stabilizer + 0.5% iron ion stabilizer Agent + 3% mutual solvent + water;

[0055] Agent C: 10% Hcl + 1-3% high temperature drainage aid + 2-5% high temperature corrosion inhibitor + 1-3% clay stabilizer + 0.5% iron ion stabilizer + 3% mutual solvent + water;

[0056] Agent D: 2% ammonium chloride + 3% high temperature drainage aid + water;

[0057] The volume ratio of agent A to agent B is 1:2; the volume ratio of agent B to agent C is 4:1; the injection amount of agent D is the volume of the injection pipeline, and the total inject...

Embodiment 2

[0065] An acidizing plug-removing agent for deep volcanic rock gas reservoirs, comprising the following components by weight:

[0066] Agent A: 12% Hcl + 2% high temperature corrosion inhibitor + 1% active thickener + 1% clay stabilizer + 0.5% iron ion stabilizer + 3% co-surfactant + water.

[0067] Agent B: 12% Hcl + 3% co-surfactant + 2% high temperature corrosion inhibitor + 1% active thickener + 3% fluorine salt + 3% retarded acid + 1% clay stabilizer + 0.5% iron ion stabilizer Agent + 3% mutual solvent + water;

[0068] Agent C: 10% Hcl + 1-3% high temperature drainage aid + 2-5% high temperature corrosion inhibitor + 1-3% clay stabilizer + 0.5% iron ion stabilizer + 3% mutual solvent + water;

[0069] Agent D: 2% ammonium chloride + 3% high temperature drainage aid + water;

[0070] The volume ratio of agent A to agent B is 1:2; the volume ratio of agent B to agent C is 4:1; the injection amount of agent D is the volume of the injection pipeline, and the total injectio...

Embodiment 3

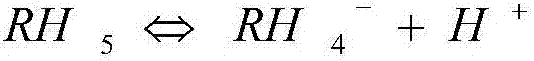

[0078] An acidizing plug-removing agent used in deep volcanic rock gas reservoirs, its retardation evaluation experiment is as follows:

[0079] In this experiment, it is evaluated by comparing with soil acid and domestic commonly used fluoboric acid system. The objects of dissolution are all the cuttings of the Yingcheng Formation in the volcanic gas reservoir of a certain gas field.

[0080] The experimental formula is as follows:

[0081] 1# soil acid 12%HCL+3%HF

[0082] 2# Fluoroboric acid 12%HCL+5%HBF 4

[0083] 3# 12% Hcl + 3% sodium salicylate + 2% high temperature corrosion inhibitor + 1% cetyl trimethyl salicylate + 3% ammonium fluoride + 3% citric acid + 1% ammonium chloride + 0.5% Tetrasodium EDTA + 3% Ethylene Glycol Butyl Ether + Water

[0084] Experimental process: The soil acid system has the fastest dissolution rate for volcanic rock powder, followed by the fluoboric acid system, and the slowest is the acidification plugging remover for 3# volcanic rock g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com