A prefabricated buckling-resistant steel plate shear wall considering both load bearing and energy dissipation

A steel plate shear wall, prefabricated technology, applied in the direction of walls, earthquake-proof, protective buildings/shelters, etc., can solve the problems of inconvenient construction, inability to transmit force, complex structure, etc., to reduce the burden of columns, reduce shaft The effect of enhancing force and energy dissipation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

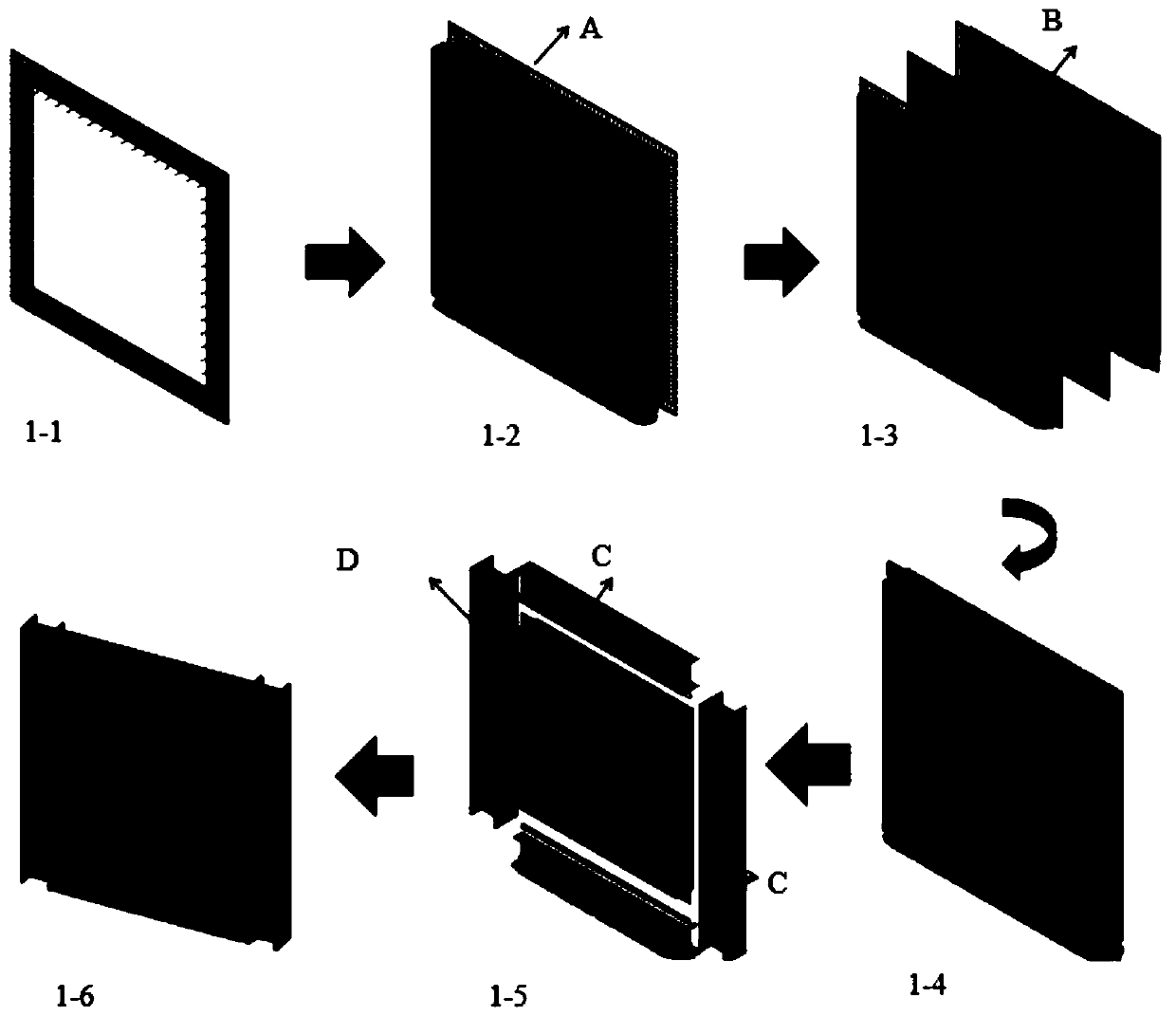

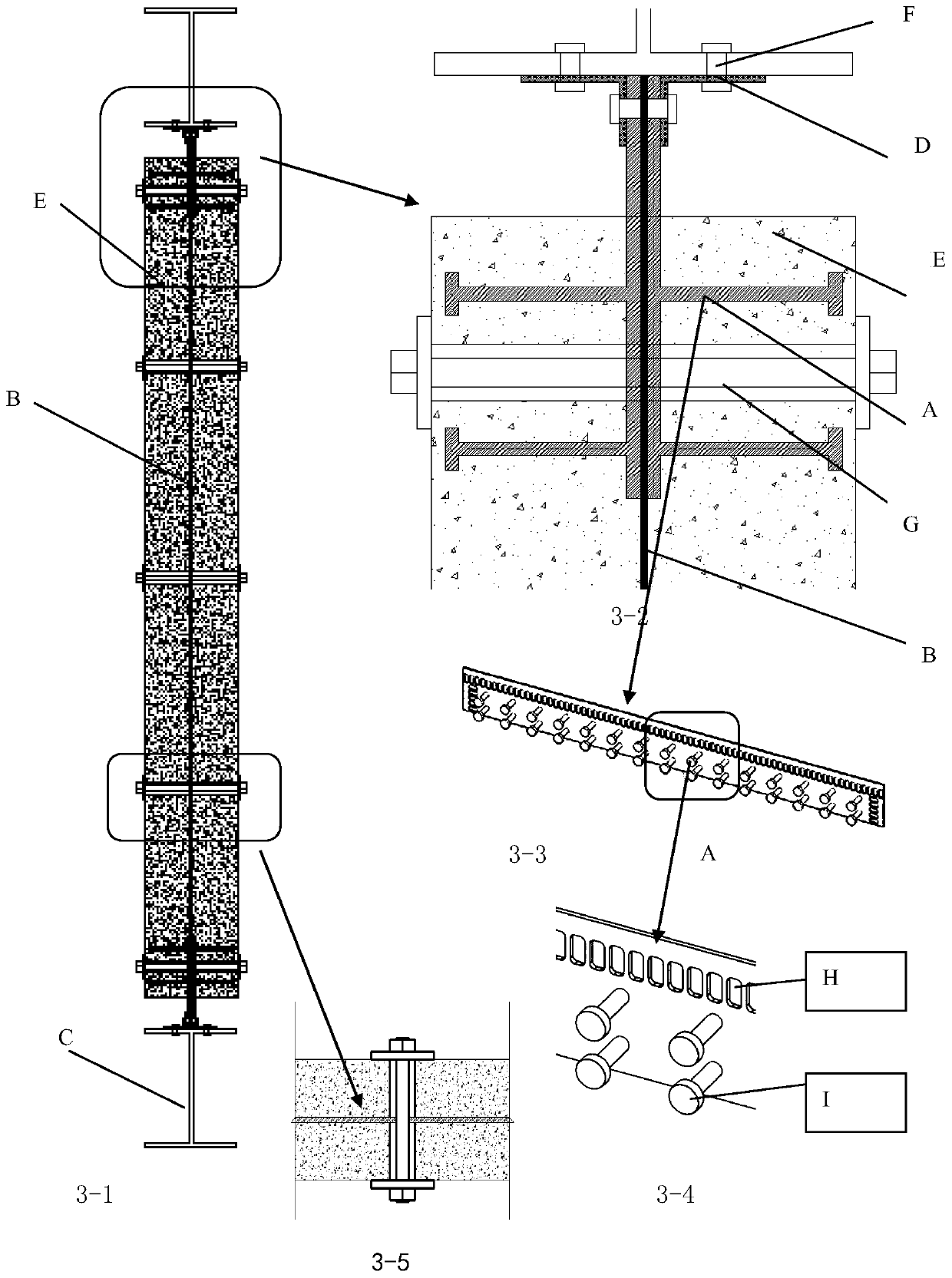

[0041] refer to Figure 1-3 As shown, a prefabricated buckling-resistant steel plate shear wall with both load bearing and energy dissipation is characterized in that it includes: edge-constrained beams and columns, prefabricated concrete wall panels and three-part components with embedded steel plates, prefabricated concrete wall panels Including concrete cover plate, energy-dissipating load-bearing steel plate and concrete filled inside the cover plate, through the first concrete cover-concrete-first energy-dissipating load-bearing steel plate-embedded steel plate-second energy-dissipating load-bearing steel plate-concrete- The sequential connection of the second concrete cover slab is perpendicular to the aforementioned connection direction, and the energy-dissipating load-bearing steel plate and the embedded steel plate are respectively connected to the edge-constrained beam-column.

[0042] The energy-dissipating load-bearing steel plate and the edge-constrained beam-colu...

Embodiment 2

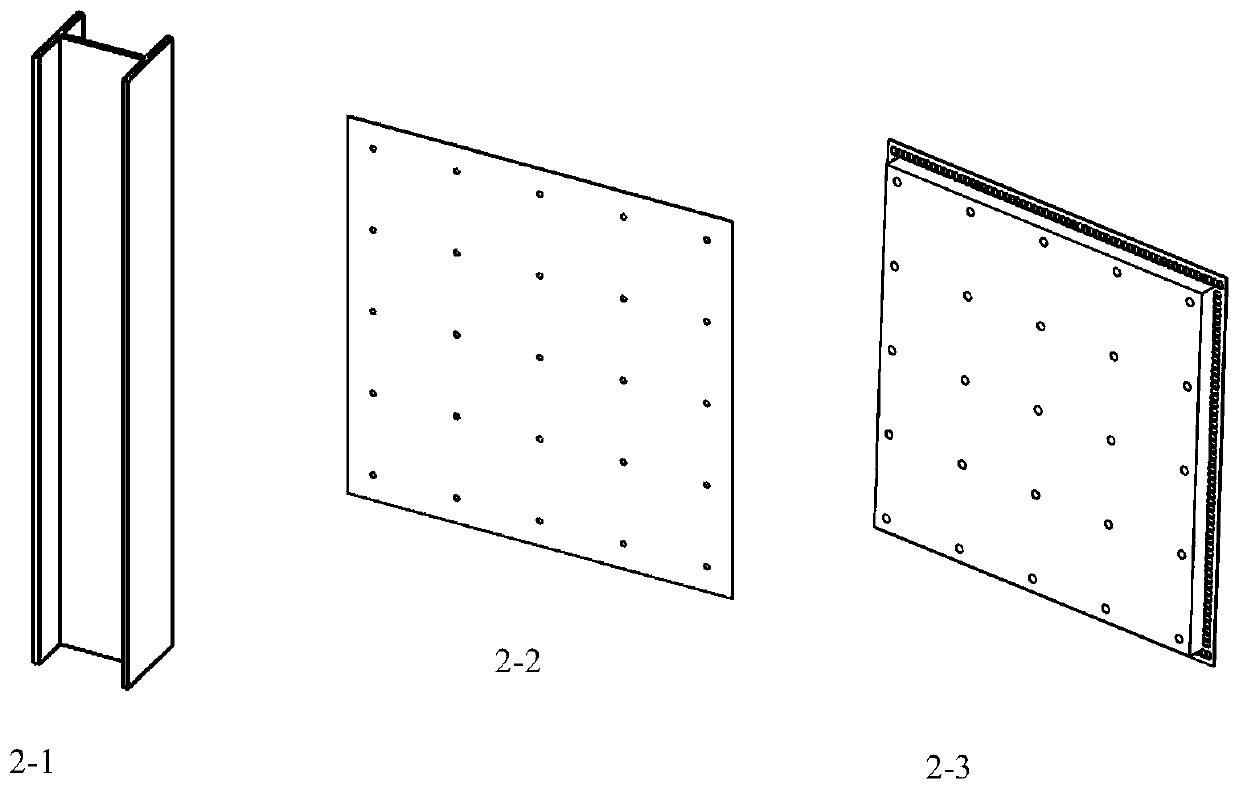

[0044] In the technical solution of Embodiment 1, the edge-constrained beams and columns are approximately in the shape of "I", and the upper and lower horizontal lengths of the "I" shape are equal. The energy-dissipative load-bearing steel plate is in the shape of "∏", the first energy-dissipative load-bearing steel plate and the second energy-dissipative load-bearing steel plate form an approximate "North" shape, and the two "North" characters extend downward vertically, and the embedded steel plate Fill in the gap in the middle of the word "North".

[0045] The beam-column constrained by the first edge, which is approximately in the shape of "I", is connected with the top end of the shape of "North" formed by the first energy-dissipating load-bearing steel plate and the second energy-dissipating load-bearing steel plate. The first energy-dissipating load-bearing steel plate and the second The two "vertical" downward extending ends formed by the two energy-dissipating and lo...

Embodiment 3

[0048] In the technical solution of Embodiment 1 or 2, the energy-dissipating load-bearing steel plate and the embedded steel plate are provided with more than one square hole and connected by bolts.

[0049] The preferred energy-dissipating load-bearing steel plate can be steel with a height of 300mm and a thickness of 10mm with a low yield point. Among them, 100mm is opened at the opening of the energy-dissipating load-bearing steel plate of the concrete wall panel and the edge-constrained beam-column frame. The opening form can be a rectangular hole, with a height of 60mm and a width of 30mm, and a spacing of 38mm. The remaining 200mm is buried on the side of the concrete wall panel and the embedded steel plate, and the built-in part will have two layers of studs connected to the steel plate to increase the anchoring effect of the concrete wall panel on the energy-dissipating and bearing steel plate. In addition, in the other concrete The steel bar and the energy-dissipatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com