Deodorant and anti-mold diatomite product and preparation method thereof

A technology of odor-proof and anti-mildew diatomite and diatomite, which is applied in the field of deodorization and anti-mold diatomite products and preparation, can solve the problems of unfavorable temperature control, unfavorable production process, high process requirements, etc., and achieve low production cost , Ensure safety and environmental protection, simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

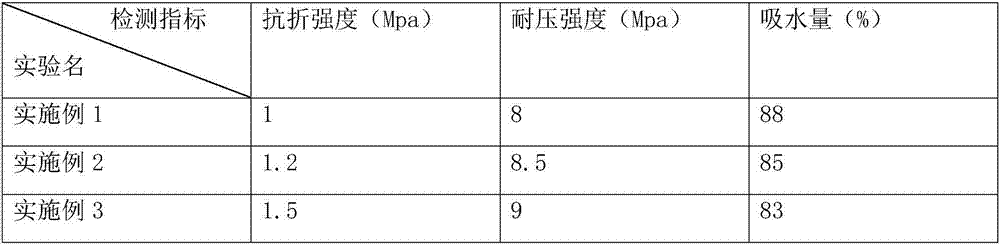

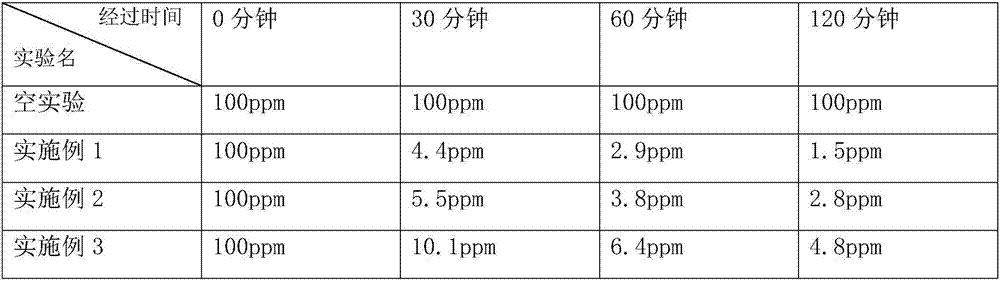

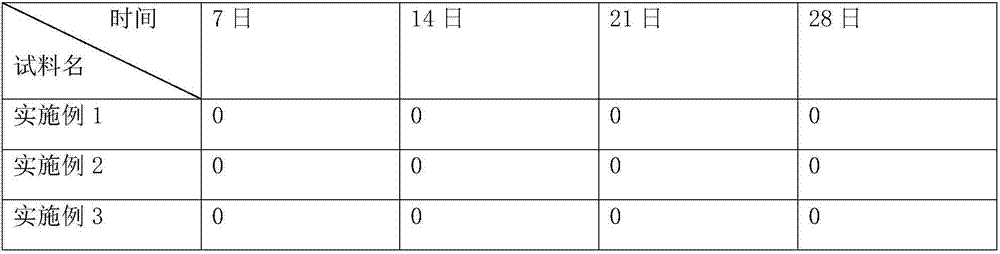

Examples

preparation example Construction

[0044] The preparation method of deodorizing and mildew-proof diatomite product comprises the following steps:

[0045] A) Raw materials are prepared, and the raw materials include: 1-30 parts of diatomite, 1-40 parts of siliceous material, 20-40 parts of lime, 3-20 parts of wood fiber, and 3-20 parts of wood fiber. 5-35 copies.

[0046] B) Grinding each raw material to more than 200 mesh;

[0047] C) each raw material prepared in step B) is mixed and fully stirred;

[0048] D) performing solidification operation on the mixed raw material prepared in step C).

[0049] Described curing operation can be by the mode of standing still naturally, and it comprises the steps:

[0050] E) Pour the mixed raw materials prepared in step C) into corresponding moulds;

[0051] F) Place the finished mold in step E) in an environment with a temperature of 15-30 degrees Celsius and a humidity of 50-95%, and let it stand for 15 days.

[0052] In addition, the curing operation can also be ...

Embodiment 1

[0057] The diatomite product includes in parts by mass: 25 parts of diatomite, 30 parts of lime, 10 parts of siliceous material, 0.5 part of wood fiber, 17.5 parts of binder and 5 parts of additive.

[0058] The binder is an inorganic binder.

[0059] The production steps of the deodorizing and mildew-proof diatomite product are as follows:

[0060] A) Prepare raw materials, said raw materials include: 25 parts of diatomite, 30 parts of lime, 10 parts of siliceous material, 0.5 parts of wood fiber, 17.5 parts of binder and 5 parts of additives in parts by mass.

[0061] B) Grinding each raw material to more than 200 mesh;

[0062] C) each raw material prepared in step B) is mixed and fully stirred;

[0063] D) Pour the mixed raw materials prepared in C) into corresponding moulds;

[0064] E) Place the mold containing the mixed raw materials in D) in an environment with a temperature of 20 degrees Celsius and a humidity of 80%, and let it stand for 15 days to obtain the corr...

Embodiment 2

[0066] The diatomite product includes in parts by mass: 10 parts of diatomite, 25 parts of siliceous material, 30 parts of lime, 15 parts of wood fiber, 0.4 part of cellulose, 21 parts of binder, additive for 5.5 servings.

[0067] The production steps of the deodorizing and mildew-proof diatomite product are as follows:

[0068] A) Prepare raw materials, said raw materials include in parts by mass: 10 parts of diatomite, 25 parts of siliceous material, 30 parts of lime, 15 parts of wood fiber, 0.4 part of cellulose, and 21 parts of binder , the additive is 5.5 parts.

[0069] B) Grinding each raw material to more than 200 mesh;

[0070] C) fully mixing the raw materials prepared in step B);

[0071] D) the mixed raw material prepared in step C) is used to prepare an embryo body through a slurry flow process;

[0072] E) sending the embryo body prepared in step D) into an autoclave, under 7Mpa saturated steam pressure, constant pressure for 18 hours, to prepare samples;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com