Environment-friendly and safe type coating

A safe, environmentally friendly and friendly technology, used in cement coatings and other directions, can solve the problems of causing cancer, respiratory diseases, damage to the human immune system, etc., and achieve the effect of improving adhesion and ensuring environmental protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

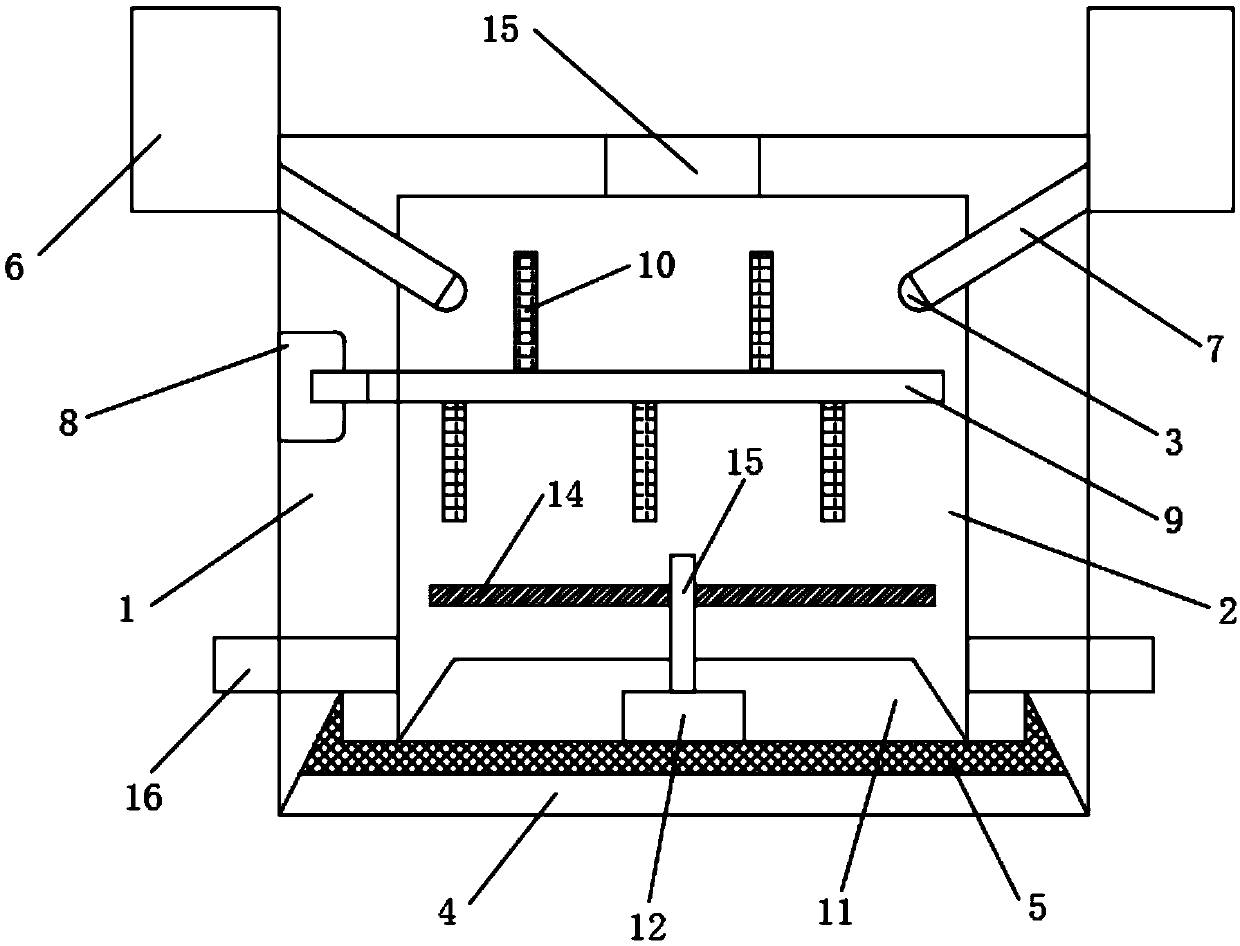

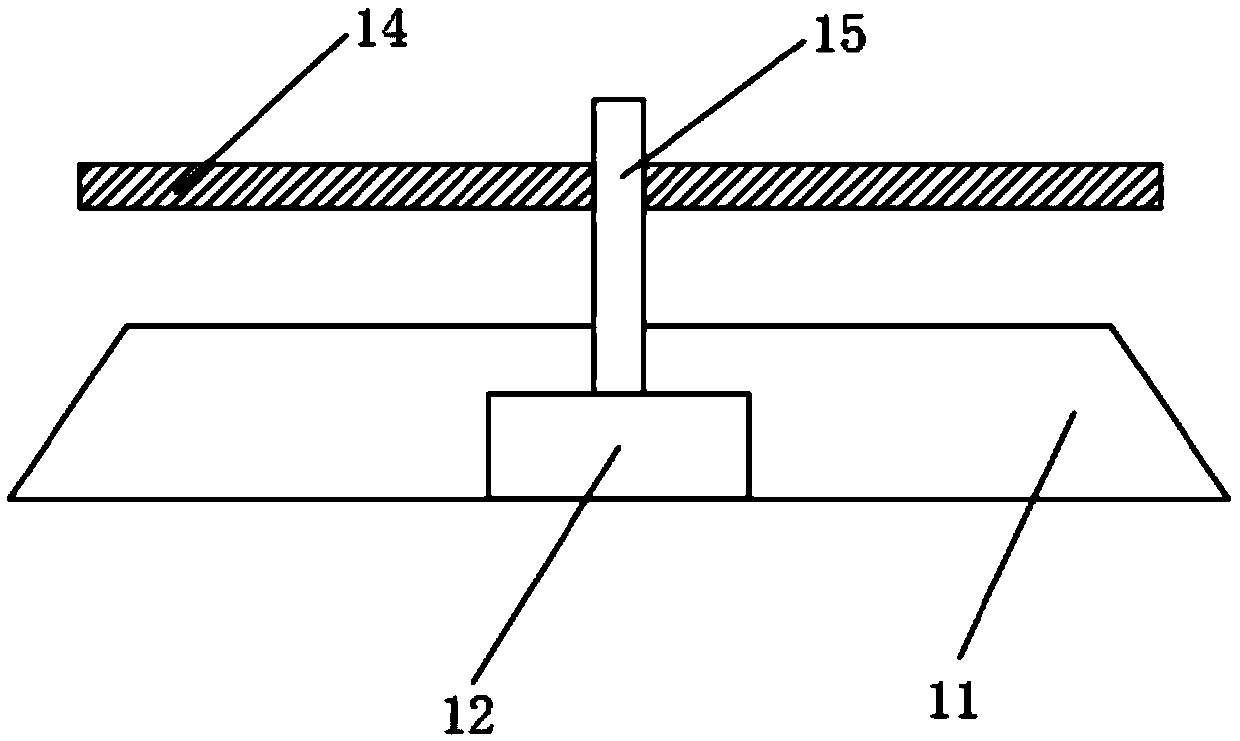

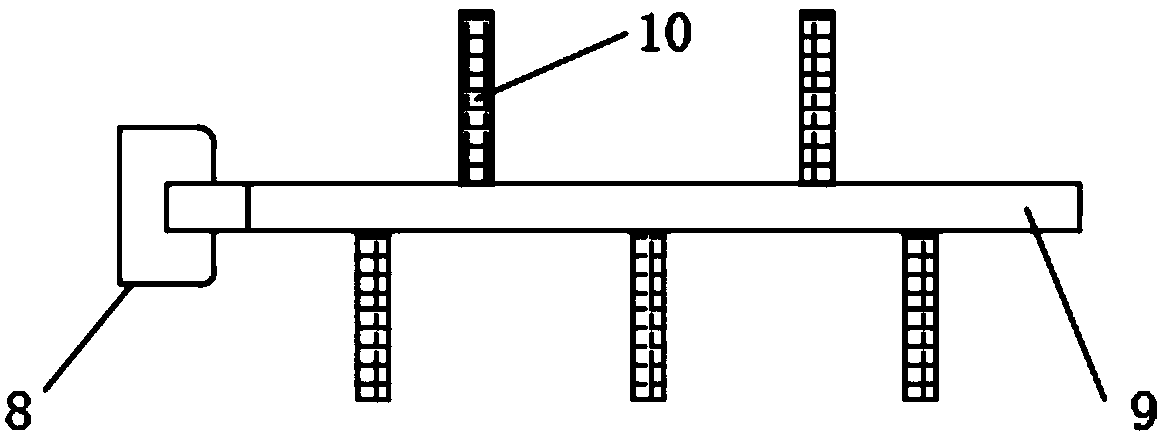

Image

Examples

Embodiment 1

[0037] An environment-friendly, safe and environment-friendly paint, the paint includes components and their mass contents are: 2.5-10.5 parts of water-soluble resin, 65-88 parts of filler, 1.5-8.4 parts of pigment, 9-22 parts of curing agent parts, thickener 0.2-0.35 parts, dispersant 0.22-0.55 parts, defoamer 0.11-0.25 parts.

[0038] The ingredients included in the filler and their mass contents are respectively: 32-45 parts of white cement, 5.8-10.5 parts of talcum powder, 2-5.8 parts of magnesium oxide and 30-65 parts of calcium carbonate.

[0039] The curing agent is set with aliphatic amine or alicyclic or polyamide, and the thickener is set with cellulose or cellulose ether. The dispersant is set in the form of tripolyphosphate or polymer homopolycarboxylate.

Embodiment 2

[0041] An environment-friendly, safe and environment-friendly paint, the paint includes components and their mass contents are: 2.5-10.5 parts of water-soluble resin, 65-88 parts of filler, 1.5-8.4 parts of pigment, 9-22 parts of curing agent parts, thickener 0.2-0.35 parts, dispersant 0.22-0.55 parts, defoamer 0.11-0.25 parts.

[0042] The ingredients included in the filler and their mass contents are respectively: 32-45 parts of white cement, 5.8-10.5 parts of talcum powder, 2-5.8 parts of magnesium oxide and 30-65 parts of calcium carbonate.

[0043] The curing agent is set with aliphatic amine or alicyclic or polyamide, and the thickener is set with cellulose or cellulose ether.

[0044] The dispersant is set in the form of tripolyphosphate or polymer homopolycarboxylate.

[0045] The filler also includes porous powdered quartz, the content of which is 8-17 parts. The particle size d of the porous powdered quartz is 3-6 μm, and the specific surface area M is 6.2-8.5 m 2...

Embodiment 3

[0061] An environmentally friendly, safe and environment-friendly coating, the coating includes components and their mass contents are: 2.5 parts of water-soluble resin, 65 parts of filler, 1.5 parts of pigment, 9 parts of curing agent, 0.2 part of thickener, 0.22 parts of dispersant, 0.11 parts of defoamer.

[0062] The ingredients included in the filler and their mass contents are respectively: 32 parts of white cement, 5.8 parts of talcum powder, 2 parts of magnesium oxide, and 30 parts of calcium carbonate.

[0063] The curing agent is set with aliphatic amine or alicyclic or polyamide, and the thickener is set with cellulose or cellulose ether.

[0064] The dispersant is set in the form of tripolyphosphate or polymer homopolycarboxylate.

[0065] The filler also includes porous powdered quartz, the content of which is 8 parts.

[0066] The particle size d of the porous powdered quartz is 3-6 μm, and the specific surface area M is 6.2-8.5 m 2 / g; its surface has numerou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com