Optical cement, optical cement film and preparation method

A technology of optical adhesive and photoinitiator, applied in the direction of adhesive, film/sheet adhesive, adhesive additive, etc., can solve the problem of low refractive index, poor reliability, high temperature and low temperature resistance, ultraviolet light resistance and resistance High temperature and high humidity performance, etc., to achieve the effect of high refractive index, high mechanical strength, high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of described optical glue, comprises the following steps:

[0041] The optical glue is prepared by mixing liquid rubber, acrylic modified resin, tackifying resin, photoinitiator and acrylate monomer.

[0042] In the preparation process of the optical adhesive of the technical solution of the present invention, the acrylic monomer is divided into two parts, which are marked as the first acrylic monomer and the second acrylic monomer: first, the photoinitiator and the first One part of acrylate monomer is mixed at room temperature, so that the photoinitiator is completely dissolved in the acrylate monomer, and A mixed solution is obtained; then the acrylic / methacrylic acid modified resin, liquid rubber and the second part of acrylate monomer Mix the body and heat it to 90°C, then add the tackifying resin, stir to mix the different components evenly, then cool to room temperature, add the storage stabilizer to prepare the B mixture; slowly add A to B, ...

Embodiment 1

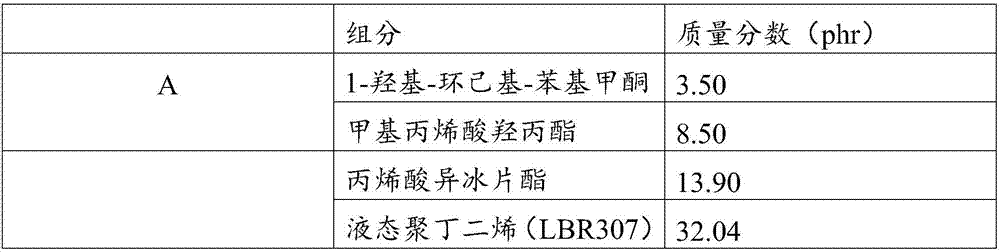

[0054] Different composition distribution ratio in the embodiment 1 of table 1

[0055]

[0056]

[0057] Preparation method of optical adhesive film:

[0058] Step 1: Mix the quantitative 1-hydroxy-cyclohexyl-phenyl ketone and hydroxypropyl methacrylate shown in Table 1 for 30 minutes at room temperature. After all solid substances are completely dissolved, mark it as A mixing liquid;

[0059] The second step: mix the quantitative acrylic-modified polyisoprene, liquid polybutadiene, and isobornyl acrylate shown in Table 1 and heat to 90 degrees Celsius, add tackifying resin, disperse and stir for 60 minutes, and make different groups Mix evenly, then cool to room temperature, add p-benzoquinone, marked as B mixed solution.

[0060] Step 3: Slowly add the mixed solution A to the mixed solution B, stir for 30 minutes, and vacuumize for 45 minutes. After the different components are mixed uniformly without air bubbles, the optical glue is prepared.

[0061] Step 4: coat...

Embodiment 2

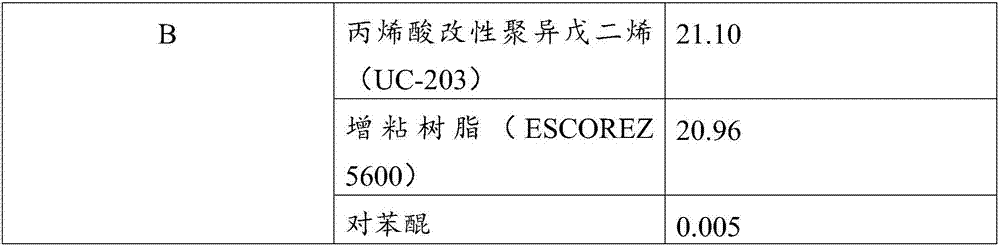

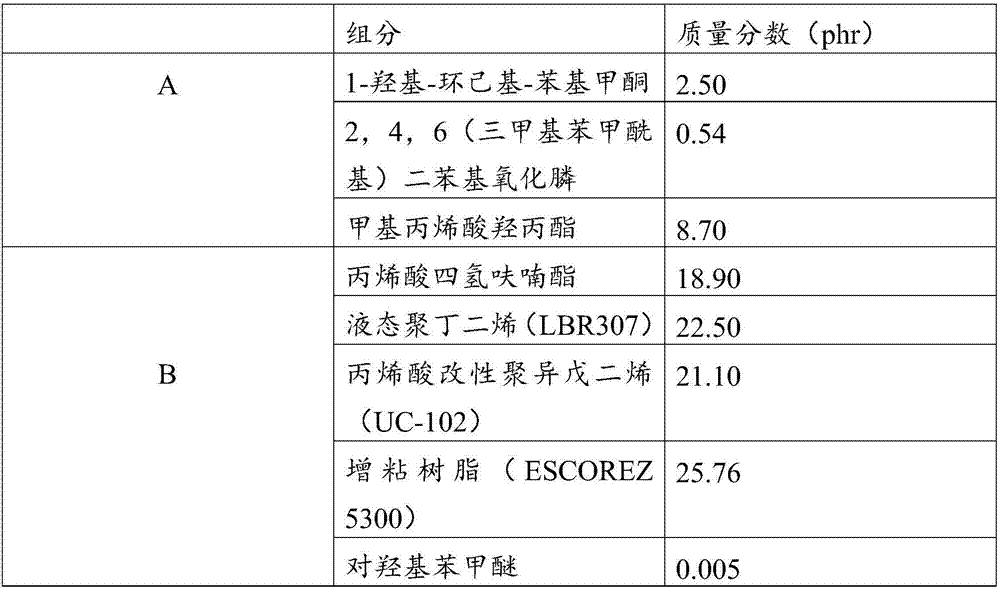

[0063] The distribution ratio of different groups in the embodiment 2 of table 2

[0064]

[0065] Preparation method of optical adhesive film:

[0066] The first step: quantitative 1-hydroxyl-cyclohexyl-phenyl ketone, 2,4,6 (trimethylbenzoyl) diphenyl phosphine oxide and hydroxypropyl methacrylate shown in table 2, in Mix at room temperature for 30 minutes, and when all solid substances are completely dissolved, mark it as a mixed solution;

[0067] The second step: mix the quantitative acrylic-modified polyisoprene, liquid polybutadiene, and tetrahydrofuryl acrylate shown in Table 2 and heat to 90 degrees Celsius, add tackifying resin, disperse and stir for 60 minutes, and make different components Mix well, then cool to room temperature, add p-hydroxyanisole, marked as B mixed solution.

[0068] Step 3: Slowly add the mixed solution A to the mixed solution B, stir for 30 minutes, and vacuumize for 45 minutes. After the different components are mixed uniformly without a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com