Efficient complex wet gel solvent replacement method

A wet gel and complex technology, which is applied in the field of complex wet gel preparation, can solve the problems of rough and simple replacement methods, high consumption of organic solvents, and agglomeration between microscopic particles, so as to shorten the replacement time and improve the effect , the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

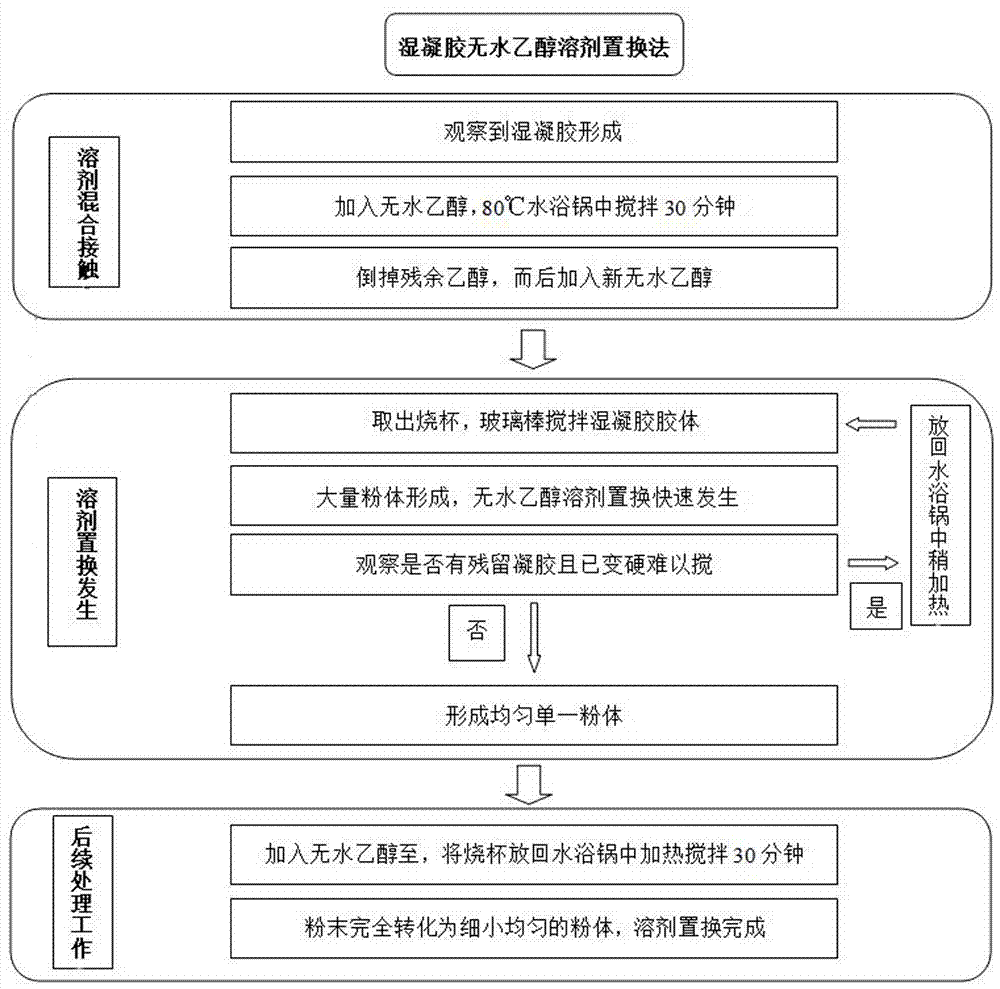

Image

Examples

Embodiment 1

[0028] Strontium cobalt iron oxide and citric acid complex gel are used as raw materials, and absolute ethanol is used as the replacement solvent. The main equipment required in the process: 1 heat-collecting magnetic stirring water bath, 1 magnetic stirring bar, 100ml beaker 1, 1 glass stirring rod.

[0029] The specific operation process and phenomena are as follows:

[0030] 1) Put a total of 15ml of strontium cobalt iron oxide and citric acid complex gel into a 100ml beaker. Stir the wet gel, when the liquid level of the wet gel no longer drops with time and heating and stirring, a preliminary wet gel is formed;

[0031] 2) Add absolute ethanol below 20°C to the wet gel in step 1) to 85ml of the beaker, and continue magnetic stirring for 30min. During this process, add absolute ethanol continuously to keep the liquid level higher than 60ml;

[0032] 3) Remove the beaker from the water bath, remove the residual absolute ethanol on the upper layer of the wet gel in step 2)...

Embodiment 2

[0037] Using strontium cobalt iron oxide and citric acid complex gel as raw materials, acetone as replacement solvent, the main equipment needed in the process: 1 heat-collecting magnetic stirring water bath, 1 magnetic stirring bar, 1 100ml beaker , 1 glass stirring rod.

[0038] The specific operation process and phenomena are as follows:

[0039] 1) Put a total of 15ml of strontium cobalt iron oxide and citric acid complex gel into a 100ml beaker, place the beaker in a heat-collecting magnetic stirring water bath at 15°C, put the magnetic stirring bar into the beaker, and magnetically Stir the wet gel, when the liquid level of the wet gel no longer drops with time and heating and stirring, a preliminary wet gel is formed;

[0040] 2) Add acetone below 20°C to the wet gel in step 1) to 85ml of the beaker, and continue magnetic stirring for 30min;

[0041] 3) Remove the beaker from the water bath, remove the residual acetone on the upper layer of the wet gel in step 2), add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com