Optical right-angle reflector and manufacture method thereof

A right-angle reflector and a manufacturing method are applied in the fields of optics and semiconductor technology, and can solve the problems of inability to return to the original path, and achieve the effects of low price, reduced weight, and high manufacturing precision.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] An embodiment of the present application provides a method for manufacturing an optical right-angle mirror, which is used for manufacturing an optical right-angle mirror on a single crystal silicon substrate.

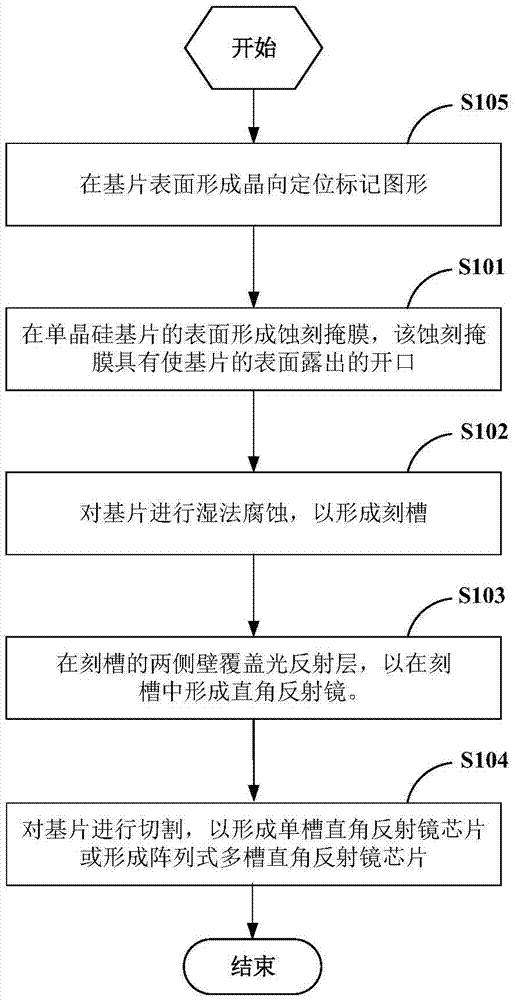

[0043] figure 1 is a schematic diagram of the manufacturing method of the optical rectangular mirror, such as figure 1 As shown, the manufacturing method includes:

[0044] S101. Form an etching mask on the surface of the substrate, the etching mask has an opening exposing the surface of the substrate, and the substrate is a single crystal silicon wafer;

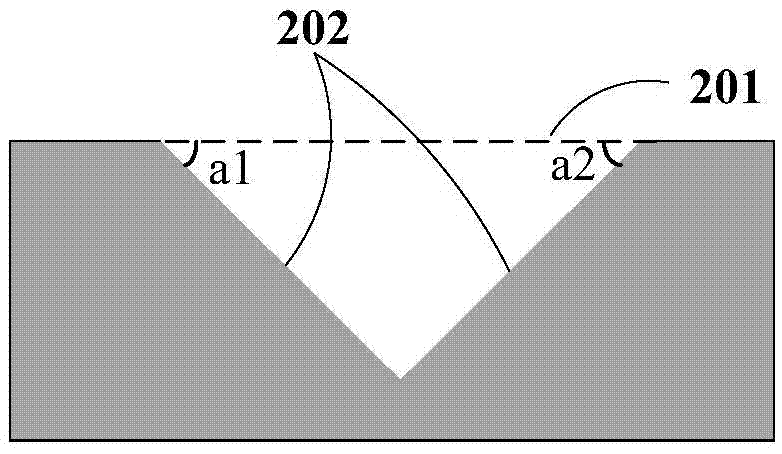

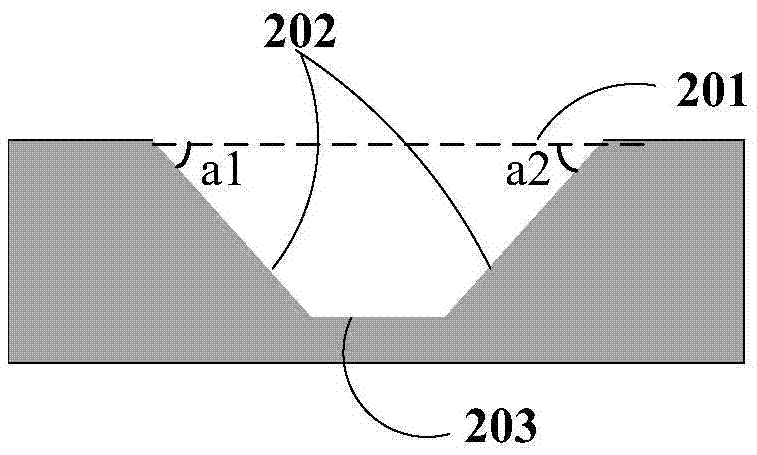

[0045] S102. Perform wet etching on the substrate formed with the etching mask to form a groove, the groove has at least two sidewalls perpendicular to each other, and the two sidewalls are single crystal silicon (110) crystal faces; and

[0046] S103 , covering the two side walls of the groove with a light reflection layer, so as to form a right-angle mirror on the surface of the groove.

[0047] According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com