A high-adsorption porous composite film used for adsorbing PM2.5

A composite film, high adsorption technology, used in conjugated synthetic polymer man-made filaments, separation methods, dispersed particle separation and other directions, can solve the problems of single structural unit, limited function and other problems, achieve large specific surface area and improved mechanical properties , the effect of high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

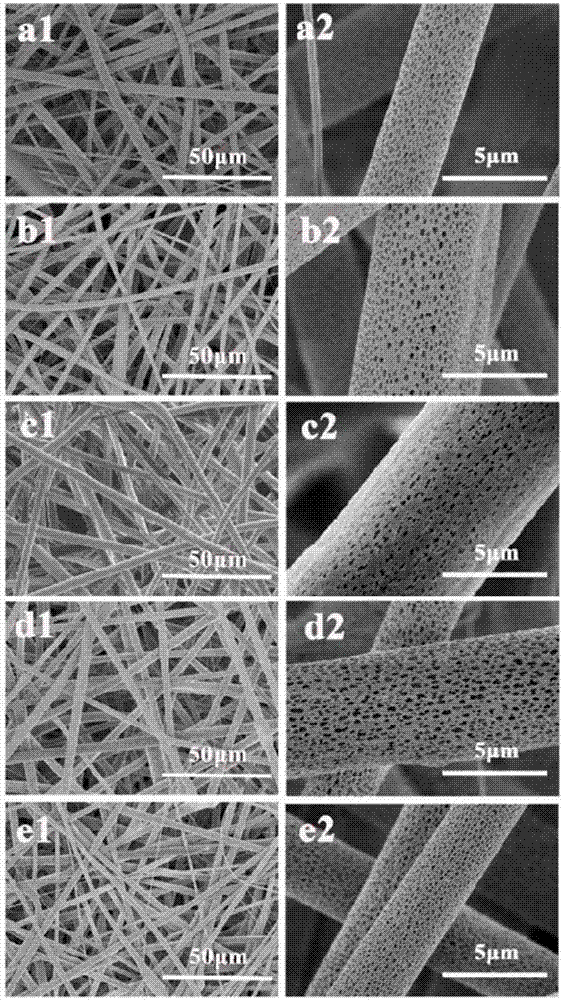

[0029] Weigh 13.10 mg of ZIF-8 and dissolve it in 10 mL of dichloromethane, ultrasonically disperse for 30 min, add 1.297 g of polylactic acid (ZIF-8: polylactic acid = 1:99), stir magnetically for 3 h to fully dissolve, and obtain the electrospun liquid. The electrospinning solution was electrospun with an electrospinning device at a temperature of 20°C and a relative humidity of 50%. Porous composite film. figure 1 (b1) and (b2) are SEM images of PLA: ZIF-8 electrospun fiber membranes with a ratio of 99:1. It can be seen that the polylactic acid electrospun fiber membranes under this condition have a porous structure. The mechanical performance test is carried out by a microcomputer-controlled electronic universal testing machine. The mechanical performance test results: the tensile strength is 1.81MPa, and the elongation at break is 60.12%. The adsorption efficiency is defined as the ratio of the mass of PM2.5 adsorbed by the film to the mass of the film in ten minutes, a...

Embodiment 2

[0031] Weigh 36.13mg of ZIF-8 and dissolve it in 10mL of dichloromethane, ultrasonically disperse for 30min, add 1.7707g of polylactic acid (ZIF-8: polylactic acid = 2:98), stir magnetically for 3h to fully dissolve, and obtain the electrospun liquid. Use an electrospinning device to electrospin the electrospinning solution at a temperature of 25°C and a relative humidity of 60%, set the voltage at 25KV, propel the spinning solution at a speed of 1mL / h, and receive a distance of 20cm to obtain porous composite film. figure 1 (c1) and (c2) are SEM images of PLA:ZIF-8 electrospun fiber membranes with a ratio of 98:2. It can be seen that the polylactic acid electrospun fiber membranes under this condition have a porous structure. The mechanical performance test is carried out by a microcomputer-controlled electronic universal testing machine. The mechanical performance test results: the tensile strength is 2.86MPa, and the elongation at break is 100.51%. The ratio of the mass o...

Embodiment 3

[0033] Weigh 44.17 mg of ZIF-8 and dissolve it in 10 mL of dichloromethane, ultrasonically disperse for 30 min, add 1.4280 g of polylactic acid (ZIF-8: polylactic acid = 3:97), stir magnetically for 4 h to fully dissolve, and obtain an electrospinning solution . The electrospinning solution was electrospun with an electrospinning device at a temperature of 30°C and a relative humidity of 60%. The voltage was set at 23KV, the advancing speed of the spinning solution was 0.1mL / h, and the receiving distance was 23cm. Porous composite film. figure 1(d1) and (d2) are SEM images of PLA: ZIF-8 electrospun fiber membranes with a ratio of 97:3. It can be seen that the polylactic acid electrospun fiber membranes under this condition have a porous structure. The mechanical performance test is carried out by a microcomputer-controlled electronic universal testing machine. The mechanical performance test results: the tensile strength is 1.80MPa, and the elongation at break is 71.52%. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com