A device for breaking pebbles into half

A pebble and hydraulic device technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve the problems of excessive use of pebbles, reduction of cement thickness, scratches on feet, etc., to ensure the effect of breaking stones and prevent deflection , the effect of accelerating corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

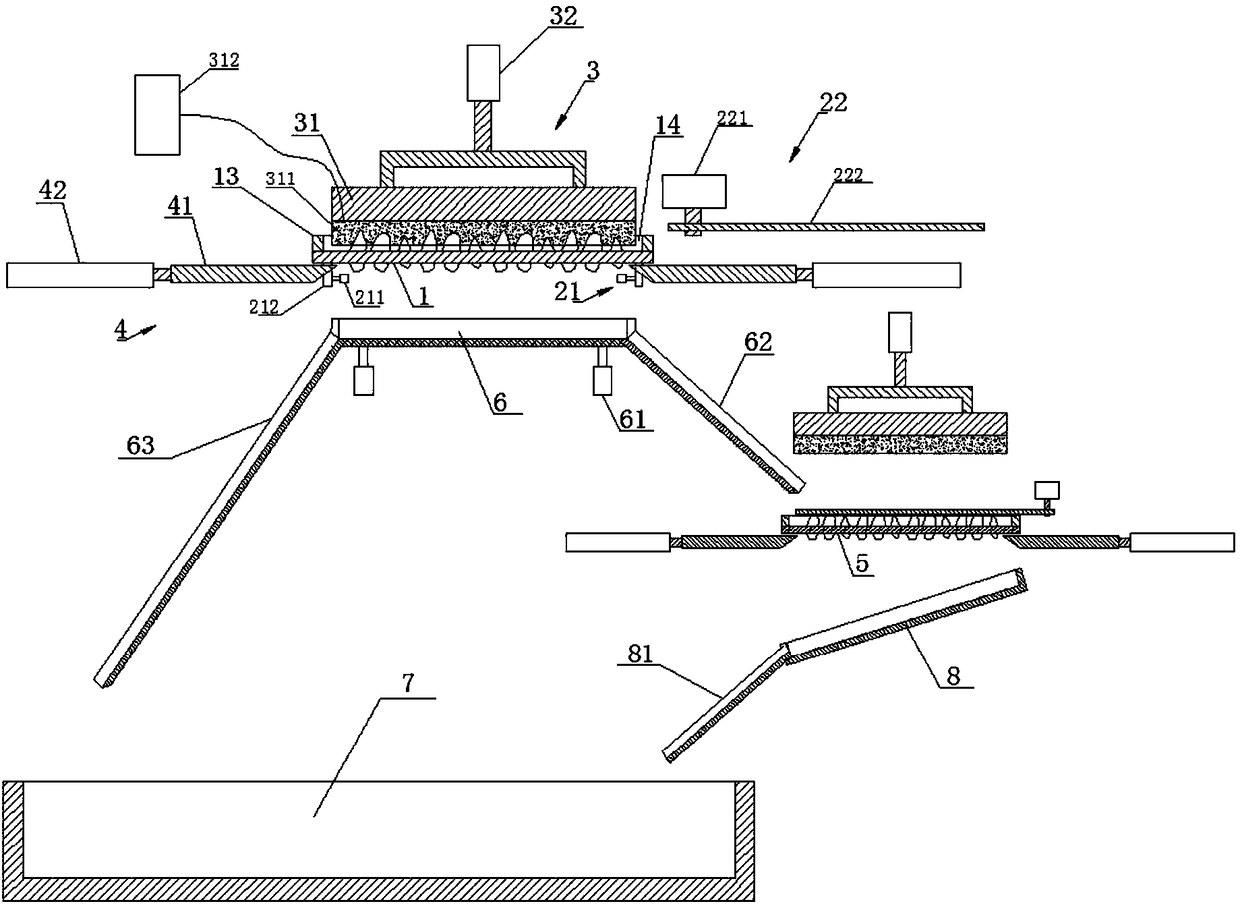

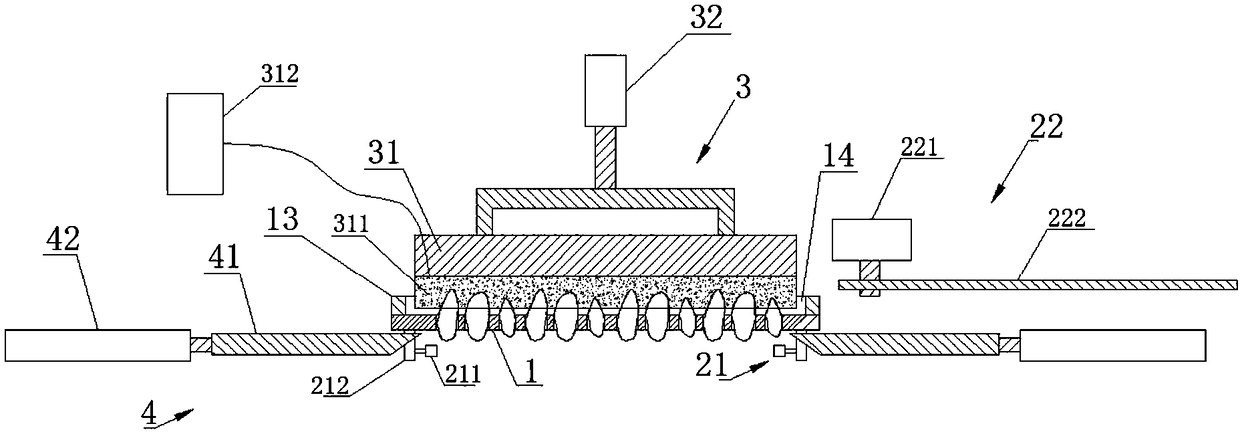

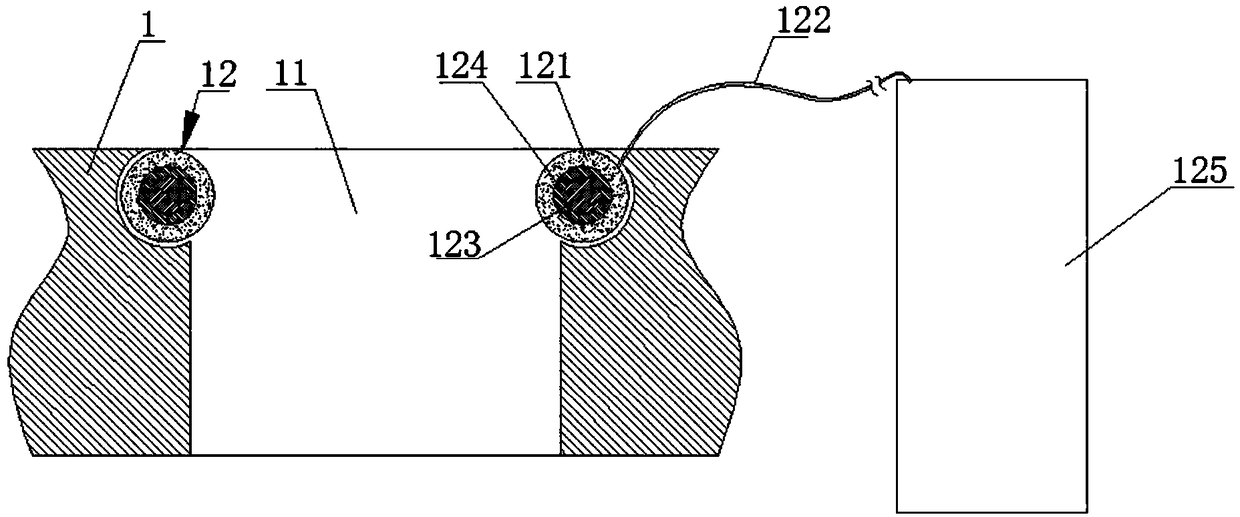

[0034] Such as Figures 1 to 4 As shown, a cobblestone breaking device includes a first half-breaking mechanism group; the first half-breaking mechanism group includes a first rigid mesh plate 1, a stone pressing mechanism 3 and a stone folding mechanism 4; the first rigid The mesh plate 1 is arranged horizontally; the outer peripheral surface of the first rigid mesh plate 1 is provided with a side plate 13; the first rigid mesh plate 1 and the side plate 13 surround a stone-holding groove 14; preferably, the The first rigid mesh plate 1 is circular; the side plate 13 is annular.

[0035] The stone pressing mechanism 3 includes an upper pressing plate 31 arranged above the first rigid mesh plate 1 and a first hydraulic device 32 that drives the upper pressing plate 31 vertically up and down; preferably, the upper pressing plate 31 is also ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com