New extraction process of L-proline

A proline and new process technology, applied in the field of L-proline extraction new process, can solve the problems of increasing environmental pressure, low light transmittance value of products, loss of proline, etc., to reduce acid and alkali consumption and drainage , high yield of finished product, and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

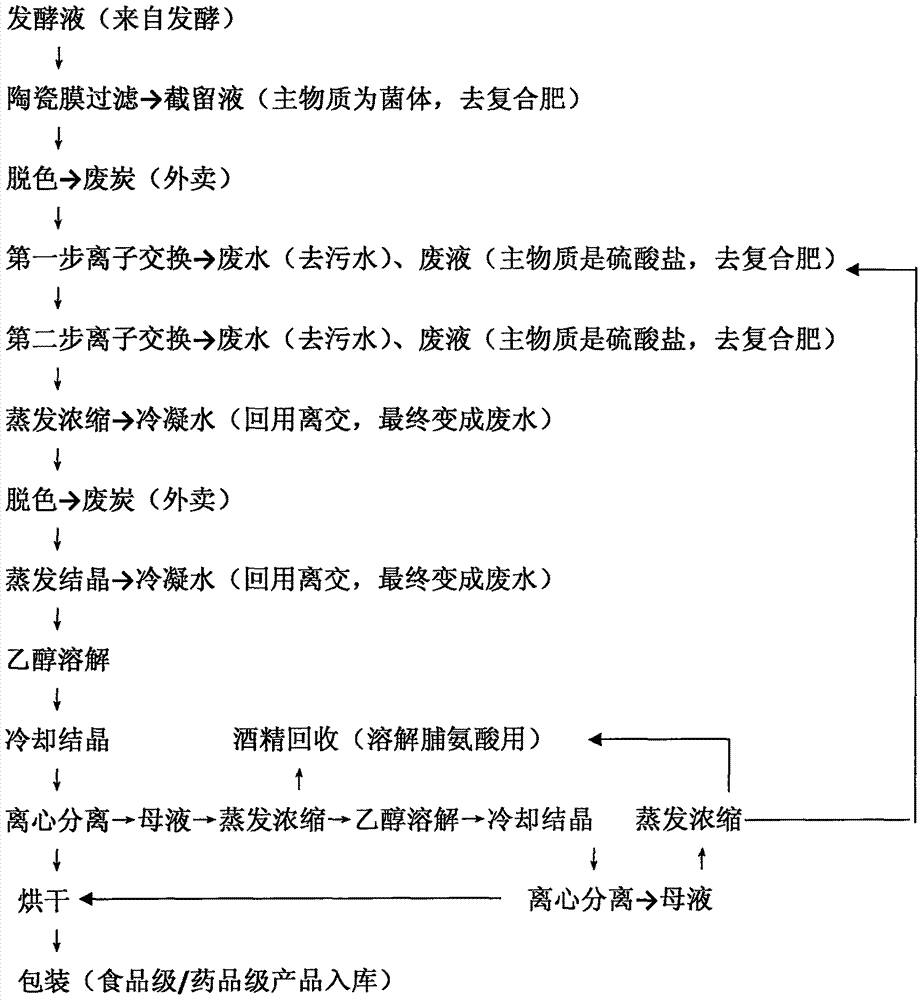

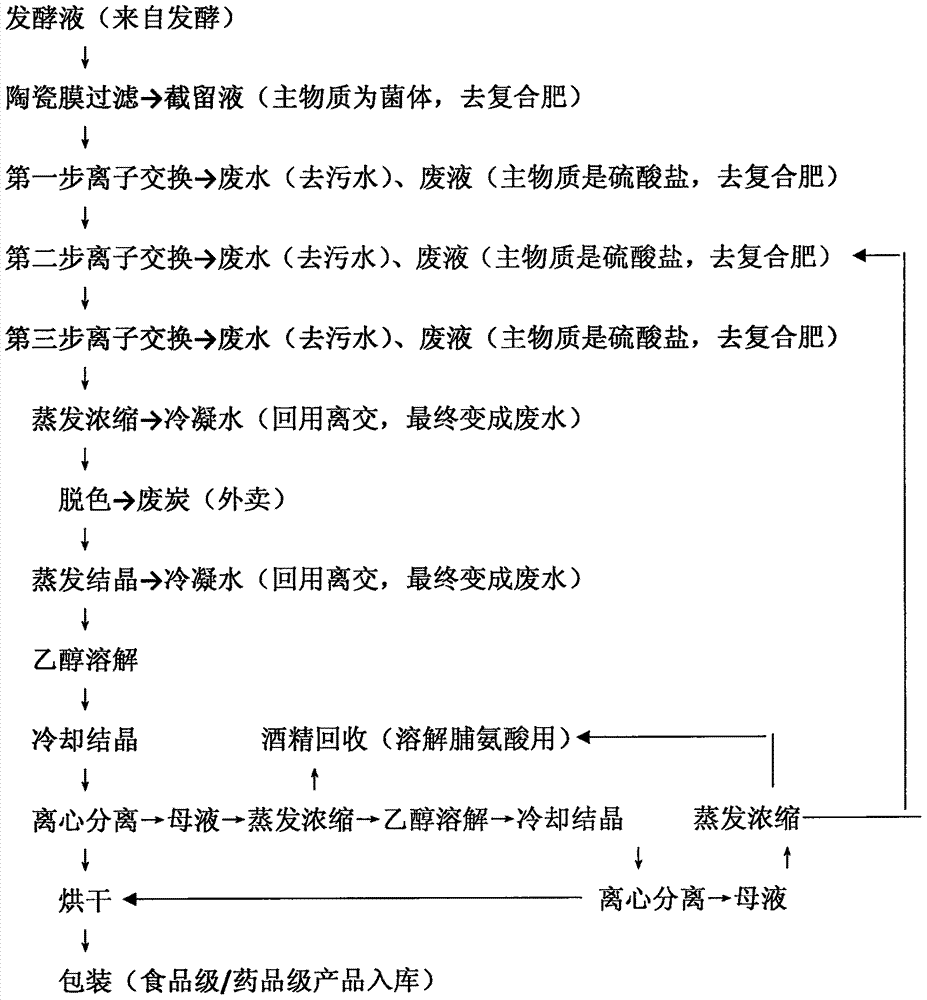

[0016] The first embodiment: figure 1 A new process is introduced and the following process steps can be seen in the figure:

[0017] 1. The fermentation liquid is filtered through a ceramic membrane, the membrane filtration temperature is 55-65°C, and the pressure is 2.0-4.0MPa. Filtrate and retained liquid are generated, and the bacteria enter the compound fertilizer system with the retained liquid; proline enters the next process with the filtrate, so as to be separated from the bacteria.

[0018] 2. The filtrate is decolorized by activated carbon, and the light transmittance of the filtrate is ≥60%; after anion and cation exchange, ammonium sulfate and other inorganic impurities are removed to obtain a relatively pure proline solution; anion and cation resins are respectively used in acid solution The lye is regenerated, and then rinsed with water to continue to be recycled; the acid solution after resin treatment contains ammonium sulfate, which enters the compound ferti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com