Packaging structure of power module

A technology of packaging structure and power module, which is applied in the directions of electrical components, electric solid devices, circuits, etc., can solve the problems of high chip thickness and pressure uniformity, complex structure of press-fit power modules, chip damage, etc., and achieves improvement. Performance and reliability, improved heat dissipation, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

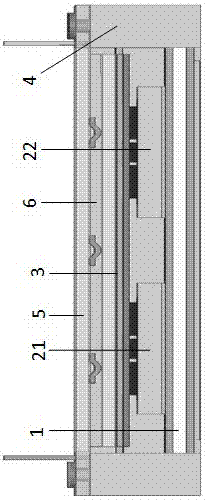

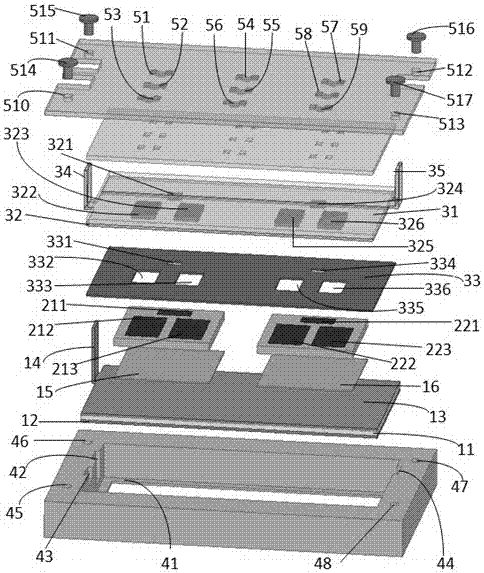

[0025] The specific implementation of the present invention will be described in detail below by taking a power module package in which two IGBT power bare chips are connected in parallel as an example in conjunction with the accompanying drawings. refer to figure 1 , the present invention is a package structure of a power module, which is composed of a lower metal directly coated copper ceramic circuit board 1, IGBT bare chips 21 and 22, an upper metal directly coated copper ceramic circuit board 3, an insulating shell 4 and an upper cover plate 5, The thermal conductive glue 6 is filled between the upper layer circuit board 3 and the upper cover plate 4 to reduce thermal resistance.

[0026] refer to figure 2 , the lower direct copper-clad ceramic circuit board 1 includes a ceramic substrate 11, a lower surface metal layer 12, and an upper surface metal layer 13, wherein the upper surface metal layer 13 is a circuit layer, and the lower surface metal layer 12 is a substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com