High-efficiency crop straw pulverizer

A crop straw and pulverizer technology, which is applied to agricultural machinery and tools, agriculture, cutting equipment, etc., can solve the problems of dust pollution to the air, difficulty in feeding and discharging, and low crushing efficiency, so as to avoid dust polluting the air and improve cutting efficiency. The effect of cutting strength and improving the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

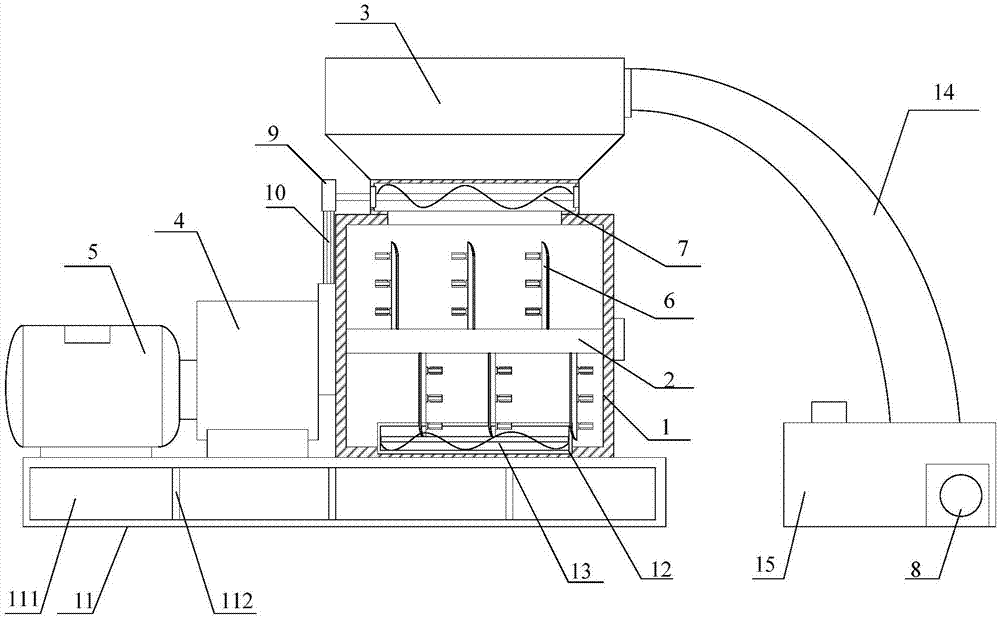

[0021] as attached figure 1 to attach figure 2 shown

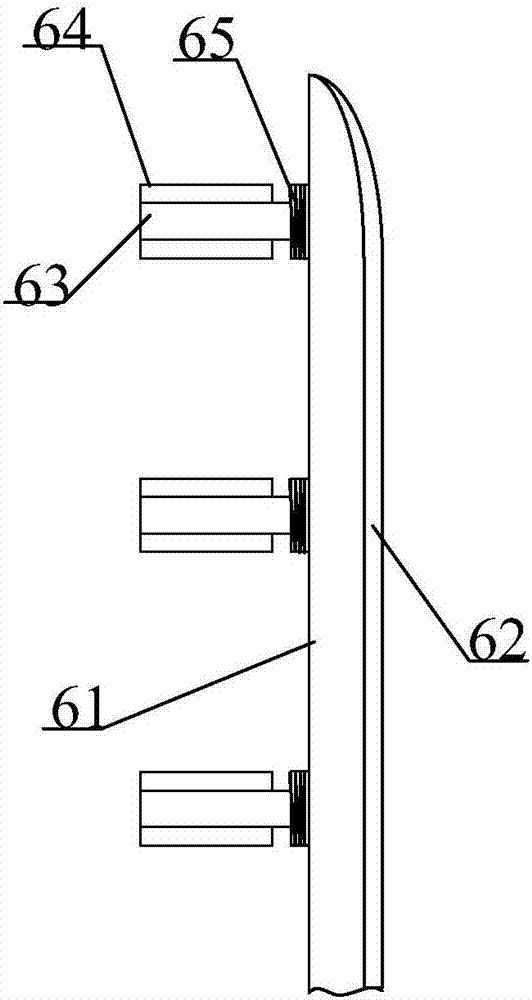

[0022] The present invention provides a high-efficiency crop straw grinder, which includes a crushing cylinder 1, a main shaft 2, a feeding port 3, a gearbox 4, a motor 5, a crushing knife 6, a spiral screw device 7, an exhaust fan 8, a pulley 9, and a conveyor belt 10. Shock-absorbing base 11, discharge port 12, screw discharge device 13, dust discharge pipe 14 and dust collection box 15, the main shaft 2 is installed in the middle of the crushing cylinder 1, and the crushing knife 6 is installed on the upper part of the main shaft 2; The feeding port 3 is located on the top of the crushing cylinder 1, and the spiral screw device 7 is installed directly below the feeding port 3; the discharge port 12 is located at the lower end side of the crushing cylinder 1, and the feeding port 3 is equipped with a spiral discharging device 13 ; The spiral spiral device 7 or the spiral discharge device 13 is connected with a pulley ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com