Novel method for preparing calamine and nitrofurazone pharmaceutical composition

A technology of nitrofurazone and calamine is applied in directions such as drug combination, drug delivery, and pharmaceutical formulation, which can solve the problems of inconvenient operation and control, easy moisture absorption of medicinal powder, easy generation of dust, etc. The effect of drug efficacy and prolongation of stratification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

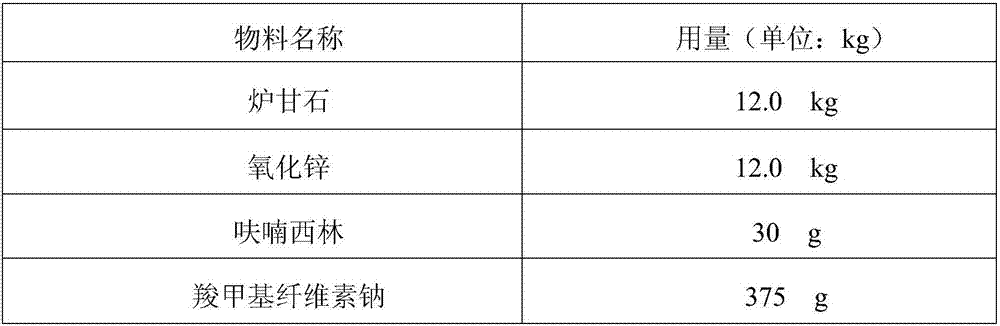

[0037] The raw and auxiliary materials are composed of:

[0038] Material name Dosage (unit: kg) Calamine 12.0kg Zinc oxide 12.0kg Furacilin 30g Sodium carboxymethyl cellulose 375g glycerin 7500ml purified water Add to a total of 150,000ml

[0039] Preparation:

[0040] (1) Put sodium carboxymethyl cellulose into an appropriate amount of purified water, and when it meets water to form a group, use a stir bar to disperse the "big group" into small pieces;

[0041] (2) Add nitrofurazone into the solution (1), stir slightly to disperse it, and avoid forming lumps;

[0042] (3) Adjust the colloid mill to the "0.01" point, add a small amount of purified water, start the colloid mill to circulate the purified water in the colloid mill, add the liquid obtained in (2) into the colloid mill, circulate for 3-5 minutes, and release;

[0043] (4) Stir the calamine powder, zinc oxide powder, glycerin, and an appropriate amount of puri...

Embodiment 2

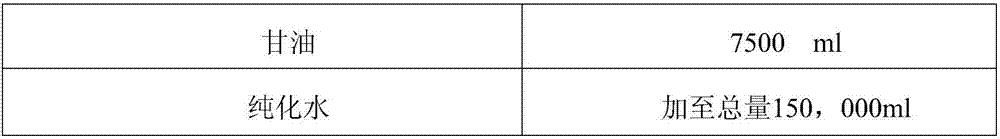

[0047] The raw and auxiliary materials are composed of:

[0048]

[0049]

[0050] Preparation:

[0051] (1) Put sodium carboxymethyl cellulose into an appropriate amount of purified water, and when it meets water to form a group, use a stir bar to disperse the "big group" into small pieces;

[0052] (2) Add nitrofurazone to 1 / 2 amount of dispersed sodium carboxymethyl cellulose slurry, and stir slightly;

[0053] (3) Adjust the colloid mill to the "0.01" point, add a small amount of purified water, start the colloid mill to circulate the purified water in the colloid mill, add the liquid obtained in (2) into the colloid mill in stages, and circulate for 3-5 minutes each time, release;

[0054] (4) Take calamine powder and zinc oxide powder, add glycerin, 1 / 2 sodium carboxymethyl cellulose slurry and an appropriate amount of purified water to stir, and stir slightly so as not to agglomerate;

[0055] (5) Add the mixed liquid obtained in (4) to the colloid mill in stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com