Preparation method of graphene-modified epoxy resin composite material

A graphene modification, epoxy resin technology, applied in the field of graphene, can solve the problems of sharp dispersion, difficult to accept in the industrial field, polluting the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

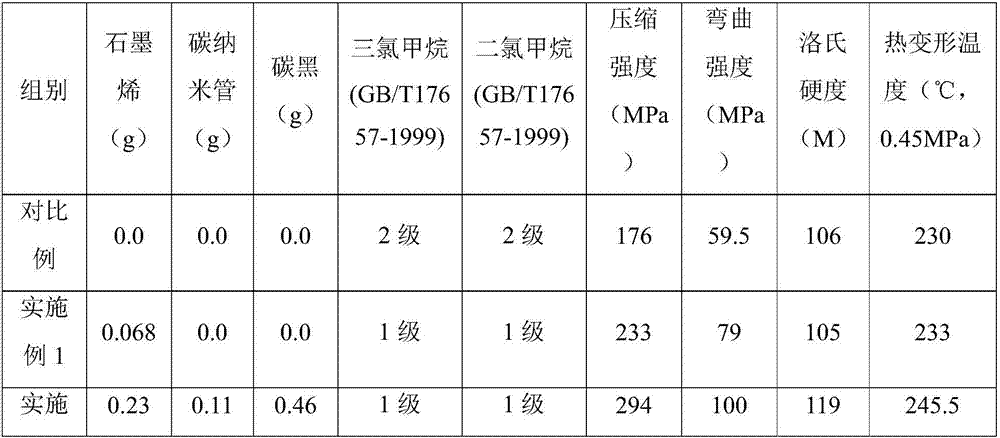

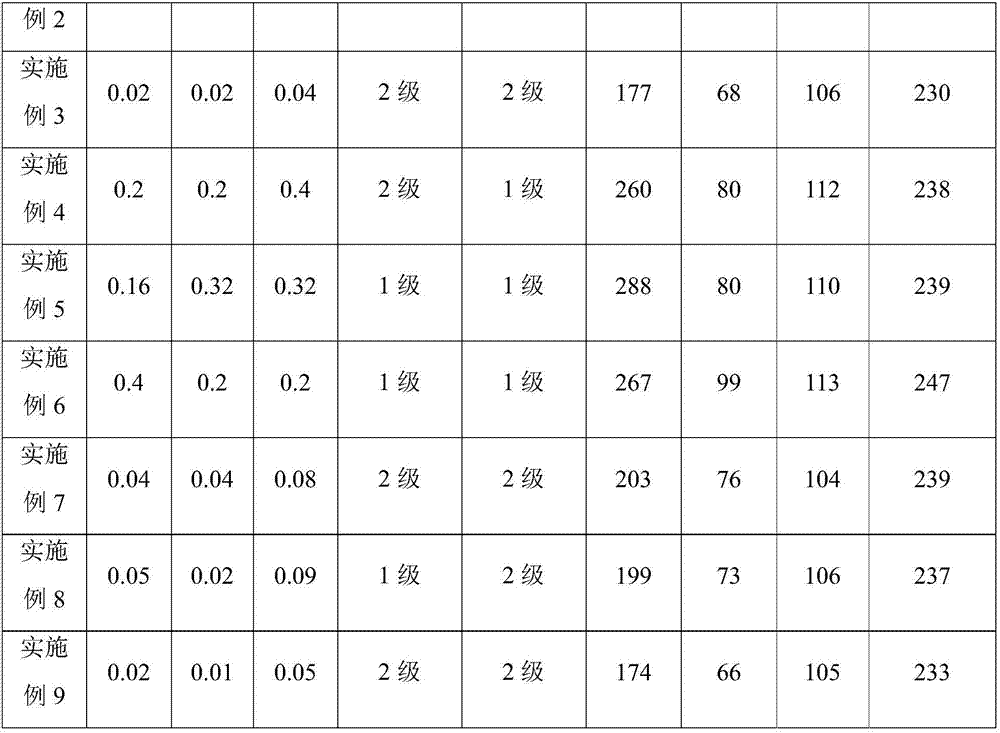

Embodiment 1

[0018] Weighing graphene, carbon nanotubes, and carbon black are 0.068g, 0.0g, and 0.0g respectively, and weigh 160.0g of epoxy resin and 136.0g of curing agent. The total amount of the three carbon nanomaterials in epoxy resin The mass fraction is 0.05wt%, and the ratio of curing agent to epoxy resin is 0.85 / 1. Pour the weighed oxygen content range of 20% to 35% graphene oxide aqueous solution (concentration is 0.1%) into the three-necked flask, and then pour the weighed epoxy resin into the three-necked flask. Mechanical decompression stirring at 50℃ / -0.3MPa for 90min, mechanical decompression stirring at 70℃ / -0.3MPa for 3h, mechanical decompression stirring at 80℃ / -0.25MPa for 3h, mechanical decompression stirring at 90℃ / -0.15MPa Stir under reduced pressure for 3 hours. At this time, the water in the composite slurry has been distilled. The detection method is to compare the water distilled with the volume of the initially added graphene oxide aqueous solution in the conica...

Embodiment 2

[0022] Weighing graphene, carbon nanotubes, and carbon black were 0.23g, 0.11g, and 0.46g respectively, and weighed 160.0g of epoxy resin and 136.0g of curing agent. The total amount of the three carbon nanomaterials in epoxy resin The mass fraction is 0.5wt%, and the ratio of curing agent to epoxy resin is 0.85 / 1. Pour the weighed oxygen content range of 20% to 35% graphene oxide aqueous solution (concentration is 0.1%) into the three-necked flask, and then pour the weighed epoxy resin into the three-necked flask. Mechanical decompression stirring at 50℃ / -0.3MPa for 90min, mechanical decompression stirring at 70℃ / -0.3MPa for 3h, mechanical decompression stirring at 80℃ / -0.25MPa for 3h, mechanical decompression stirring at 90℃ / -0.15MPa Stir under reduced pressure for 3 hours. At this time, the water in the composite slurry has been distilled. The detection method is to compare the water distilled with the volume of the initially added graphene oxide aqueous solution in the con...

Embodiment 3

[0025] Weighing graphene, carbon nanotubes, and carbon black are 0.02g, 0.02g, and 0.04g respectively, and weigh 160.0g of epoxy resin and 136.0g of curing agent. The total amount of the three carbon nanomaterials in epoxy resin The mass fraction is 0.05wt%, and the ratio of curing agent to epoxy resin is 0.85 / 1. Pour the weighed oxygen content range of 20% to 35% graphene oxide aqueous solution (concentration is 0.1%) into the three-necked flask, and then pour the weighed epoxy resin into the three-necked flask. Mechanical decompression stirring at 50℃ / -0.3MPa for 90min, mechanical decompression stirring at 70℃ / -0.3MPa for 3h, mechanical decompression stirring at 80℃ / -0.25MPa for 3h, mechanical decompression stirring at 90℃ / -0.15MPa Stir under reduced pressure for 3 hours. At this time, the water in the composite slurry has been distilled. The detection method is to compare the water distilled with the volume of the initially added graphene oxide aqueous solution in the conic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com