Seashore saline land improver, preparation method of seashore saline land improver and seashore saline land improvement method

A technology of saline-alkali soil and improving agent, applied in chemical instruments and methods, other chemical processes, agricultural machinery and implements, etc., can solve the problems of only focusing on soil, soil anti-salinity, and single composition of chemical amendments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

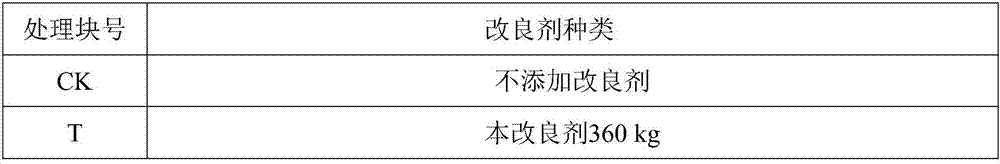

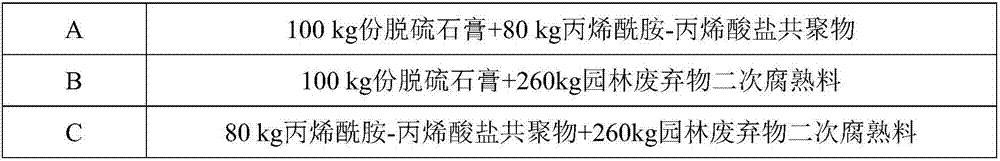

Method used

Image

Examples

Embodiment 1

[0032] Prepare the coastal saline-alkali soil modifier according to the following steps: take industrial waste gypsum and crush it, then mix the crushed industrial waste gypsum, monosodium glutamate residue, and water in a mass ratio of 30:1:2, and use a ball mill for 60 minutes to obtain an emulsion. Dry, to obtain industrial waste gypsum and monosodium glutamate waste residue mixed ground, wherein the industrial waste gypsum is phosphogypsum (by-product of phosphate fertilizer), the mixed ground is passed through a 50-200 mesh sieve (with a particle size of 75-270 μm); A fresh sample of plant waste is crushed into a size of 1cm by a crusher (model: ZP1400-700) and then subjected to aerobic composting. After it is mature, it is crushed for a second time and sieved into a particle size of 1mm for use; and then 10 parts by weight Parts of industrial waste gypsum and monosodium glutamate residue mixture, 35 parts of garden plant waste secondary crushed clinker, 0.02 parts of anion...

Embodiment 2

[0043] Prepare the coastal saline-alkali soil improver according to the following steps: first add industrial waste gypsum, MSG waste residue, and water in a ratio of 30:1:2, use a ball mill for 60 minutes to obtain an emulsion, and dry it to obtain industrial waste gypsum and MSG waste residue. Mixed grind, the industrial waste gypsum is desulfurized gypsum (by-product after flue gas desulfurization); then fresh samples of garden plant waste are pulverized into a size of 3 cm by a grinder (model: ZP1400-700) and then subjected to aerobic composting. After being decomposed, it is smashed for a second time, and then sieved into a particle size of ≤10mm for use. 20 parts by weight of industrial waste gypsum and monosodium glutamate residue mixture, 55 parts of garden plant waste, second pulverized decomposed clinker, 0.08 parts of anionic PAM (The molecular weight is 10 million and the degree of hydrolysis is 30%). Mix well; then add 15 parts by weight to the above mixture, which ...

Embodiment 3

[0047] Prepare the coastal saline-alkali soil modifier according to the following steps: take industrial waste gypsum and crush it, then mix the crushed industrial waste gypsum, monosodium glutamate residue, and water in a mass ratio of 25:1:2, and use a ball mill for 60 minutes to obtain an emulsion. Dry, to obtain industrial waste gypsum and monosodium glutamate waste residue mixed ground, wherein the industrial waste gypsum is phosphogypsum (by-product of phosphate fertilizer), the mixed ground is passed through a 50-200 mesh sieve (with a particle size of 75-270 μm); A fresh sample of plant waste is crushed into 1cm size by a crusher (model: ZP1400-700) and then subjected to aerobic composting. After it is mature, it is crushed again and sieved into a particle size of 1mm for use; then the weight is 5.2 Parts of industrial waste gypsum and monosodium glutamate residue mixture, 30 parts of garden plant waste secondary crushed clinker, 0.01 parts of anionic PAM (molecular weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com