Antibacterial soap and preparation method thereof

A soap and formulation technology, which is applied in the direction of soap detergent and other compounding agents, antibacterial drugs, chemical instruments and methods, etc., can solve the problems of high cost, complex components, and unclear antibacterial components, etc., and achieve low production costs and suppress Strong antibacterial ability and good decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

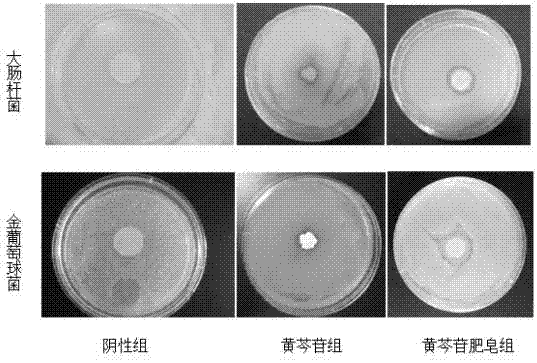

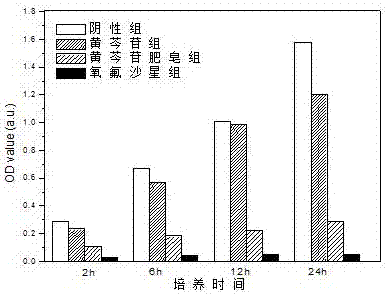

[0053] A kind of antibacterial soap, it is made of the following components by mass percentage:

[0054] Grease 40%

[0055] Sodium hydroxide solution 20%

[0056] Absolute Ethanol 10%

[0057] Glycerin 5%

[0058] Sucrose 5%

[0059] Baicalin 2%

[0060] Water 18%.

[0061] Wherein, the grease in the present embodiment is beef tallow.

[0062] In this embodiment, the molar concentration of the sodium hydroxide solution is 10 mol / L.

[0063] The preparation method of above-mentioned a kind of antibacterial soap, it may further comprise the steps:

[0064] Step 1, preparing the soap liquid: according to the formula amount, using the formula amount of butter, sodium hydroxide solution, absolute ethanol and water as raw materials, mixing and stirring evenly to prepare the soap liquid;

[0065] Step 2, saponification: Heat the soap liquid prepared in step 1 to 80°C for saponification reaction for 8 hours. After the saponification reaction is completed, add the premixed sol...

Embodiment 2

[0070] A kind of antibacterial soap, it is made of the following components by mass percentage:

[0071] Grease 50%

[0072] Sodium hydroxide solution 15%

[0073] Absolute ethanol 5%

[0074] Glycerin 4%

[0075] Sucrose 4%

[0076] Baicalin 4%

[0077] Water 18%.

[0078] Wherein, the grease in the present embodiment is castor oil.

[0079] In this embodiment, the molar concentration of the sodium hydroxide solution is 8 mol / L.

[0080] The preparation method of above-mentioned a kind of antibacterial soap, it may further comprise the steps:

[0081] Step 1, preparing soap liquid: according to the formula amount, using castor oil, sodium hydroxide solution, absolute ethanol and water as raw materials, mixing and stirring evenly to prepare soap liquid;

[0082] Step 2, saponification: Heat the soap liquid prepared in step 1 to 85°C for saponification reaction for 10 hours. After the saponification reaction is completed, add the premixed solution prepared with the formul...

Embodiment 3

[0087] A kind of antibacterial soap, it is made of the following components by mass percentage:

[0088] Grease 70%

[0089] Sodium hydroxide solution 5%

[0090] Absolute ethanol 1%

[0091] Glycerin 1%

[0092] Sucrose 1%

[0093] Baicalin 10%

[0094] Water 12%.

[0095] Wherein, the grease in the present embodiment is coconut oil.

[0096] In this embodiment, the molar concentration of the sodium hydroxide solution is 12 mol / L.

[0097] The preparation method of above-mentioned a kind of antibacterial soap, it may further comprise the steps:

[0098] Step 1, preparing the soap liquid: according to the formula quantity, using the formula quantity of oil, sodium hydroxide solution, absolute ethanol and water as raw materials, mixing and stirring evenly to prepare the soap liquid;

[0099] Step 2, Saponification: Heat the soap liquid prepared in Step 1 to 75°C for saponification reaction for 6 hours. After the saponification reaction is completed, add the premix solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com