Mold rapid molding method based on cloud manufacturing

A molding method and cloud manufacturing technology, applied in the field of cloud collaborative mold rapid prototyping, can solve the problems of prolonged mold production and processing cycle, uneven design team level, and difficulty in modifying molds, so as to promote business development, reduce production costs, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

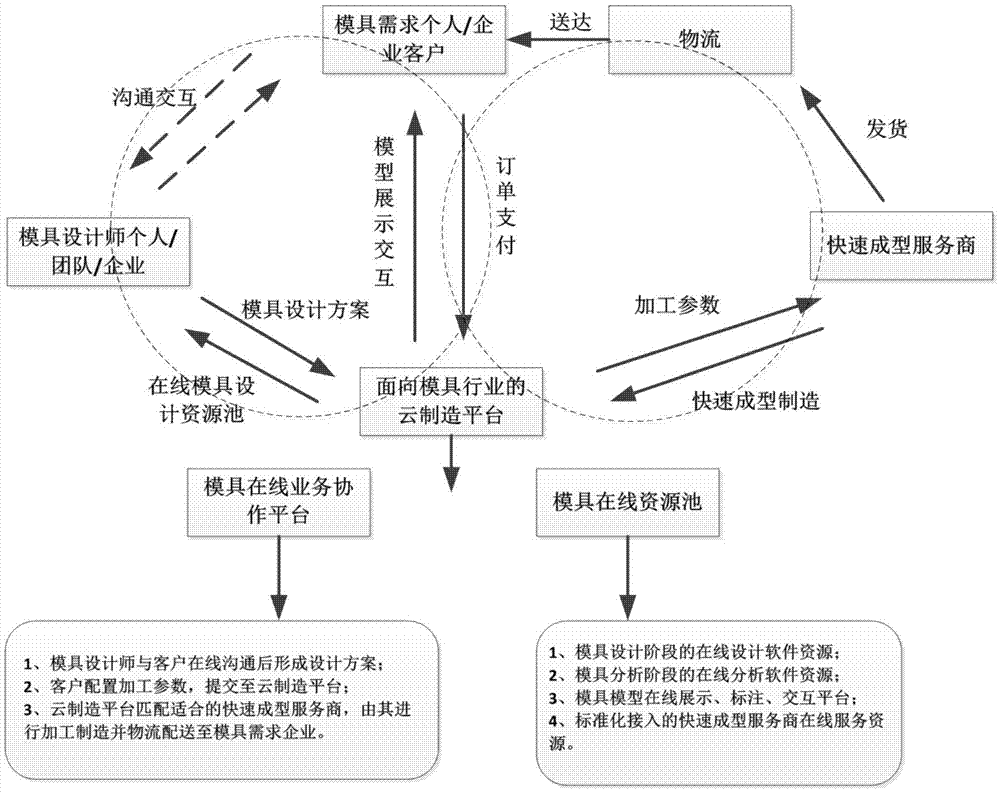

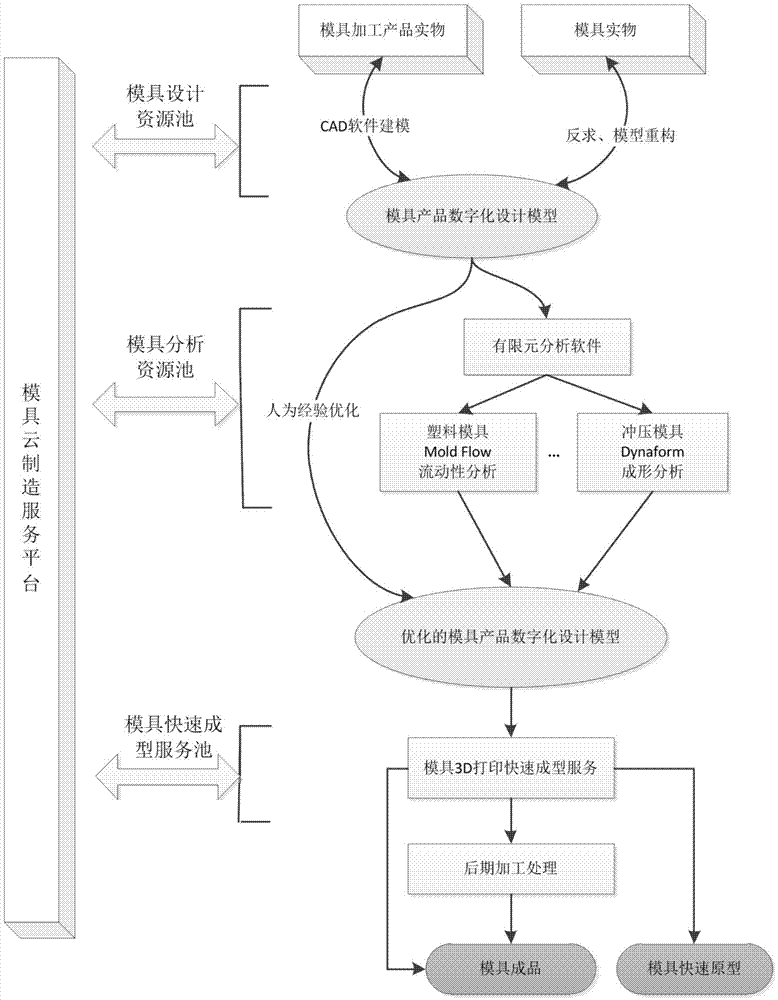

[0045]On the premise of ensuring the data security of the mold design model and convenient and fast access, the cloud manufacturing service platform distributes the complex mold design requirements of the mold users to excellent freelance designers or enterprises in the society through the online sourcing mode; through the online mold The efficient use of design software provides designers with a low-cost online design platform, and provides both parties with a safe and convenient online annotation and interaction platform ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com