Method for synthesizing MCM-48 mesoporous silica

A mesoporous silica, MCM-48 technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of pollution caused by fluoride ion environment, and achieve the effect of saving surfactant, high degree of order, and uniform pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The features of the present invention are further described below through examples, but the present invention is not limited to the following examples.

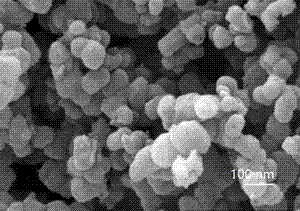

[0022] The scanning electron micrographs of the materials in the examples were measured by a DSM 962 scanning electron microscope from Zeiss Company, Germany.

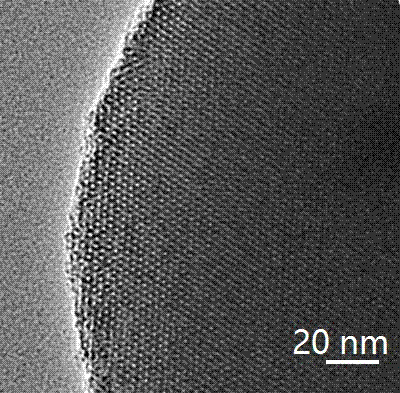

[0023] The transmission electron micrographs of the materials in the examples were measured by a Tecnai G2 F20 S-Twin type transmission electron microscope from FEI Company of the United States.

[0024] The scanning electron specific surface area, pore diameter, and pore volume of the materials in the examples were measured using an Autosorb-IQ gas adsorption instrument from Quanta Corporation, USA.

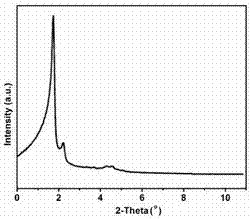

[0025] The XRD of the materials in the examples is measured by a D / max-rB X-ray diffractometer of Rigaku Corporation.

[0026] The thermogravimetric curves of the materials in the examples were measured with a DTG-60AH thermal analyzer from Shimadzu Corporation ...

Embodiment 2

[0030] Take 2.48g of tetradecyltrimethylammonium bromide and 0.13g of 2-hydroxy-3-naphthoic acid dissolved in 60 ml of water at room temperature, stir for 0.5 h to obtain A solution, another 63.11 g of Na 2 SiO 3 9H 2 Dissolve O in 60 ml of water to obtain solution B; quickly mix solution A and solution B, and add 2 mol / L sulfuric acid solution drop by drop to the above mixture under vigorous stirring until the pH is 9-10; Heated at constant temperature in an oven for 48 hours, filtered the obtained solid precipitate, washed with water and dried in air to obtain a composite product; the resulting composite product was placed in a muffle furnace and heated in air at a speed of 1.5°C / min to The product can be obtained by calcination at constant temperature at 600°C for 5 hours.

Embodiment 3

[0032] Take 2.48g tetradecyltrimethylammonium bromide and 0.35g 2-hydroxy-3-naphthoic acid dissolved in 60 ml water at room temperature, stir for 0.5 h to obtain A solution, and take another 63.11 g Na 2 SiO 3 9H 2 Dissolve O in 60 ml of water to obtain solution B; quickly mix solution A and solution B, and add 2 mol / L sulfuric acid solution drop by drop to the above mixture under vigorous stirring until the pH is 9-10; Heating at constant temperature in an oven for 48 hours, filtering the obtained solid precipitate, washing with water and drying in air to obtain a composite product; placing the obtained composite product in a muffle furnace and heating it in air at a speed of 1.5 °C / min to The product can be obtained by calcination at constant temperature at 600°C for 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com