Green and environment-friendly compound admixture for concrete

A composite admixture, green and environmentally friendly technology, which is applied in the field of composite admixtures for concrete, can solve the problems of undiscovered recycling of composite admixtures for concrete, and achieve the effects of low manufacturing cost, simple process, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

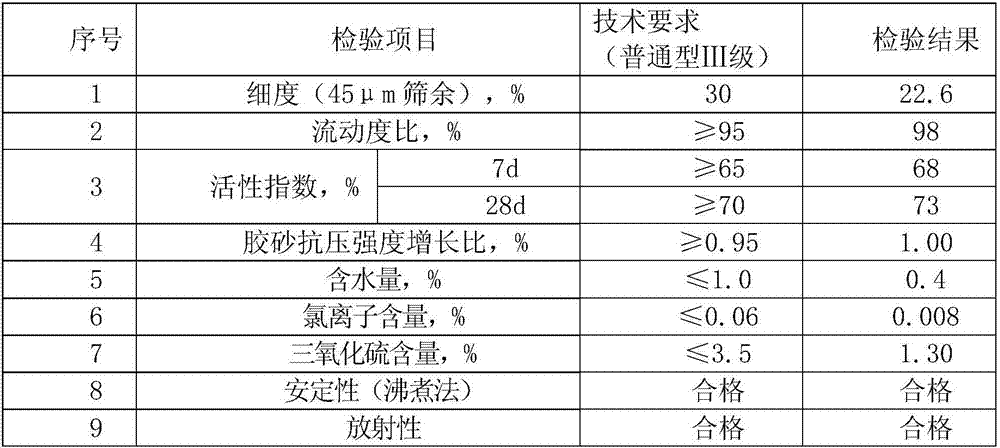

[0022] The common type III grade composite admixture produced by the green and environment-friendly concrete composite admixture formula of the present invention, its formula components and its mass percentage content are:

[0023] Cement clinker 5%, concrete filter residue 60%, waste concrete test block 34.5%, grinding aid 0.5%.

[0024] The cement clinker, concrete filter slag and waste concrete test blocks were dried and crushed respectively, mixed according to mass percentage content, then added with grinding aid, then ground and homogenized, and the fineness was controlled to be 0.045mm square hole sieve The sieve residue is less than 30%, and the compound admixture for common type III concrete of this embodiment is obtained. The composite admixture inspection result for the concrete of embodiment 1 is as follows:

[0025]

Embodiment 2

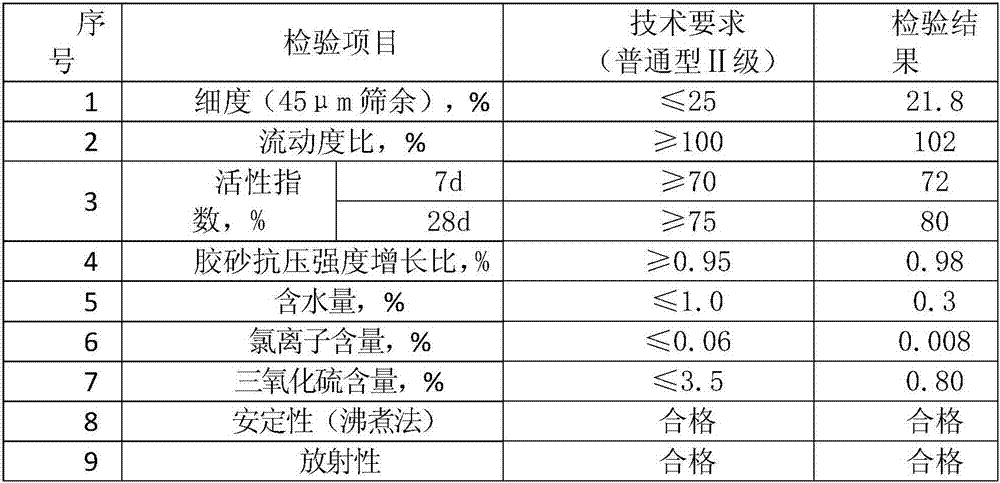

[0027] The common type II grade composite admixture produced by the green and environment-friendly concrete composite admixture formula of the present invention, its formula components and their mass percentage contents are:

[0028] Cement clinker 8-10%, concrete filter residue 29.5%, waste concrete test block 58%-60%, grinding aid 0.5%. The sum of the mass percentages of the above-mentioned components is 100%.

[0029] The cement clinker, concrete filter slag and waste concrete test blocks were dried and crushed respectively, mixed according to mass percentage content, then added with grinding aid, then ground and homogenized, and the fineness was controlled to be 0.045mm square hole sieve The sieve residue is less than 25%, and the compound admixture for ordinary type II concrete of this embodiment is obtained which is green and environment-friendly. The composite admixture inspection result for the concrete of embodiment 2 is as follows:

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com