Preparation method of basic zinc chloride

A technology of zinc chloride and zinc chloride solution, applied in chemical instruments and methods, zinc halide, zinc oxide/zinc hydroxide, etc., can solve the problems of by-product environmental pollution, high preparation cost, and high cost of wastewater treatment, and achieve Low price, simple preparation method, and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The basic zinc chloride of the present embodiment is prepared by the following method:

[0024] First prepare reagent grade zinc chloride into a zinc chloride solution containing 50g / l of zinc, and reagent grade calcium hydroxide or reagent grade calcium oxide into a suspension containing 10% calcium hydroxide, and then add 100ml of distilled water, then turn on the stirring device, and increase the temperature to 85°C at the same time, then add 400ml of zinc chloride solution and 300ml of calcium hydroxide suspension into the reaction kettle dropwise at the same time, control the pH at 4-5, and add After completion, aging for 60 minutes, the product was filtered, washed, dried at 100°C, crushed through a 75-mesh sieve, and finally the finished product was obtained.

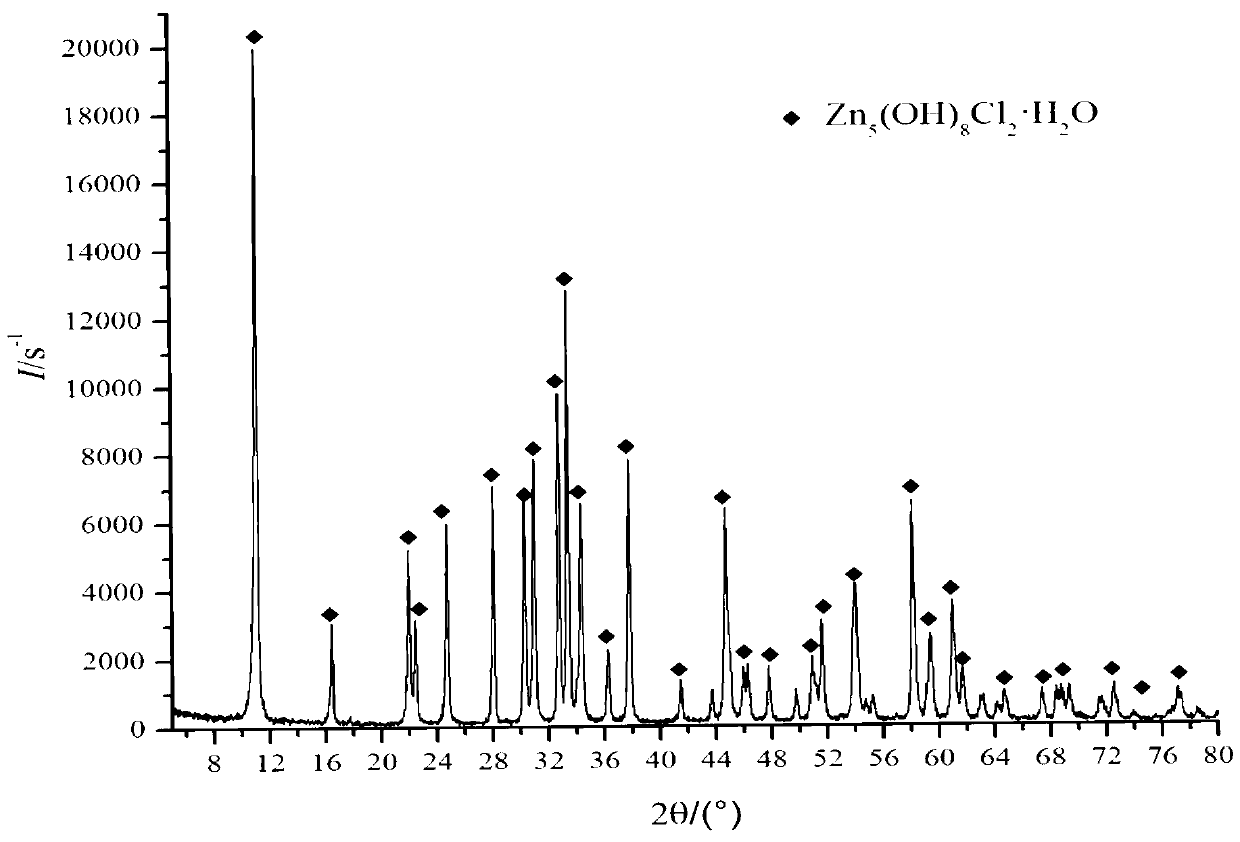

[0025] The crystal composition and structure of the finished product are detected by the XRD detection method, and the XRD spectrum of the finished product is consistent with the standard spectrum, so it c...

Embodiment 2

[0027] The basic zinc chloride of the present embodiment is prepared by the following method:

[0028] First prepare the reagent-grade zinc chloride into a zinc chloride solution containing 65g / l of zinc, then use slaked lime (or quicklime) to obtain a qualified suspension containing 20% calcium hydroxide after digestion and purification, and then go to Add 100ml of distilled water to the reaction kettle, then turn on the stirring device, and at the same time raise the temperature to 50°C, then add 200ml of zinc chloride solution and the supernatant of 100ml of calcium hydroxide suspension to the reaction kettle dropwise at the same time, Control the pH at 5.0-6.0, age for 45 minutes after feeding, filter, wash, dry at 100°C, crush and pass through a 75-mesh sieve to finally obtain the finished product.

[0029] The crystal composition and structure of the finished product are detected by the XRD detection method, and the XRD spectrum of the finished product is consistent wi...

Embodiment 3

[0031] The basic zinc chloride of the present embodiment is prepared by the following method:

[0032] ZnCl was prepared by leaching waste zinc and sub-zinc oxide soot as raw materials with hydrochloric acid. 2 , the zinc content in the zinc chloride solution after impurity removal is 100g / l, then select slaked lime to obtain qualified suspension containing calcium hydroxide 15% after digesting and purifying slag removal, then add 100ml distilled water in the reactor, then Turn on the stirring device, and at the same time keep the temperature constant to 25°C, then add 500ml of zinc chloride solution and 500ml of calcium hydroxide suspension into the reaction kettle dropwise at the same time, control the pH at 5.5-6.5, and age for 90 minutes after the addition is completed Finally, the product is filtered, washed, dried at 100°C, crushed through a 75-mesh sieve, and finally the finished product is obtained.

[0033] The crystal composition and structure of the finished produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com