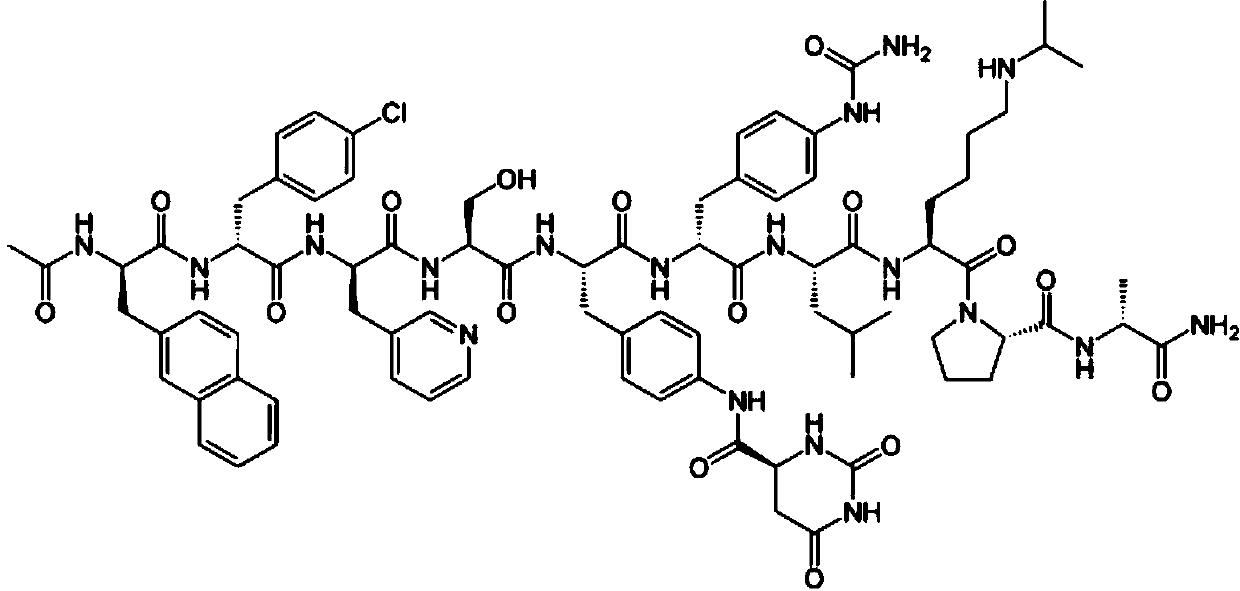

A method for preparing degarelix by solid-liquid combination

A degarelix and solution technology, which is applied in the field of solid-liquid combination preparation of degarelix, can solve the problems of high operator requirements, complicated operation, troublesome post-processing, etc. The effect of the synthesis process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1: Synthesis of Ac-D-2Nal-D-4Cpa-D-3Pal-Ser(tBu)-4Aph(Fmoc)-OH

[0066] Accurately weigh 199.6g (1.0mol) of H-D-4Cpa-OH and 127.2g (1.2mol) of sodium carbonate and dissolve them in 2400mL of water, slowly add Ac-D-2Nal-OSu THF solution (298.3 g, 1.0mol) / 2000ml, stir the reaction, TLC monitors the reaction end point, after the reaction is complete, spin off THF, add dilute hydrochloric acid in an ice-water bath to adjust the pH value of the solution to 2~3, extract 3 times with 2000ml ethyl acetate, combine organic phase, washed 3 times with 400ml of saturated brine, dried over anhydrous sodium sulfate, concentrated to 2000ml by rotary evaporation, and stood for crystallization to obtain 390.3g of Ac-D-2Nal-D-4Cpa-OH, with a yield of 82.1%.

[0067] Accurately weigh 136.3g (0.82mol) of H-D-3Pal-OH and 106.0g (1.0mol) of sodium carbonate and dissolve in 2400mL of water, slowly add Ac-D-2Nal-D-4Cpa-OSu at low temperature (2-8°C) Tetrahydrofuran solution (390.3g, 0...

Embodiment 2

[0070] Example 2: Synthesis of Ac-D-2Nal-D-4Cpa-D-3Pal-Ser(tBu)-4Aph(Fmoc)-OH

[0071] Weigh 500.0g (sub=1.0mmol / g) of CTC resin and place it in a synthesis column, wash twice with 4000mL DMF, add 4000mL DCM to swell for 30min; (tBu)-OH DCM / DMF (3 / 1, volume ratio) solution 1500ml, after stirring, add DIPEA 330ml (2000mmol), drum N 2 React for 60min, remove the reaction liquid, add DCM / CH 33000ml of OH / DIPEA (volume ratio 17:2:1) mixed solution was capped 3 times, 10min each time; then washed 6 times with DMF, a small sample was taken to measure the substitution degree of 0.75mmol / g, and the synthesis scale was 0.5mol.

[0072] The resin in the synthesis column was deprotected twice by 3000ml 20% piperidine / DMF solution, washed 6 times with DMF; then added the activated Fmoc-D-3Pal-OH / HOBT / DIC solution, reacted at room temperature for 3h, filtered off After the reaction solution, wash 6 times with DMF; then recycle the above operation, respectively react with Fmoc-D-4Cpa-OH a...

Embodiment 3

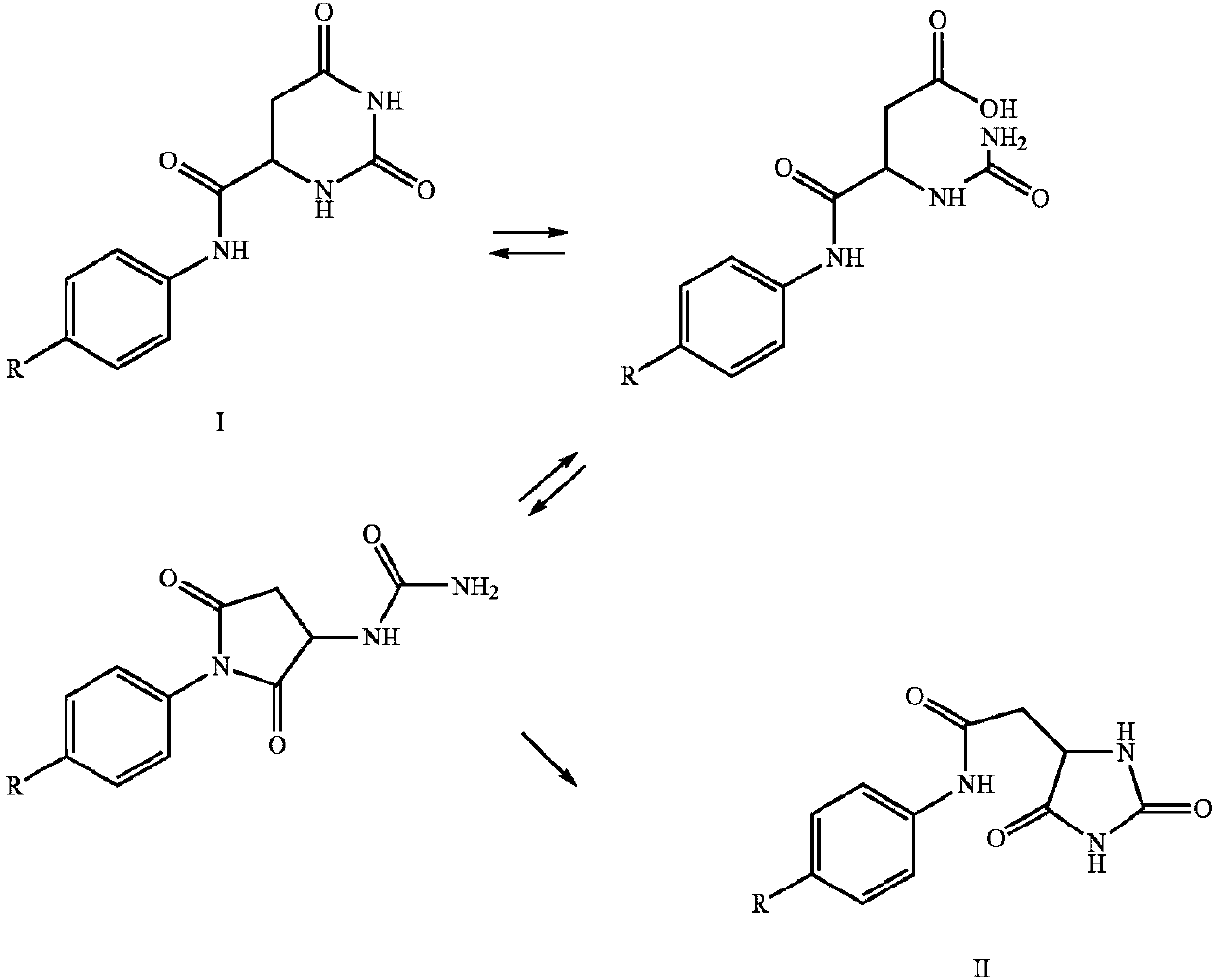

[0075] Example 3: Preparation of H-D-4Aph(Cbm)-Leu-Lys(Boc, iPr)-Pro-D-Ala-NH-Resins

[0076] Accurately weigh 220 g of RinkAmideAM resin (initial substitution degree 0.91 mmol / g) and place it in a peptide resin synthesis reactor, add 1.0 LDCM to swell for 2 h. After the swelling is completed, wash with DMF three times, 1.0 L each time, and then add 2.0 L of 20% piperidine / DMF solution for deprotection twice, for 10 min and 10 min respectively. After the deprotection was completed, the resin was washed 6 times with DMF, 2.0 L each time. Weigh 124.4g (0.40mol) of Fmoc-D-Ala-OH, 59.4g (0.44mol) of HOBt and dissolve it in 0.8L DMF, add 68mL (0.44mol) of DIC to activate, add the solution into the reactor, and react for 2h. The Kaiser test monitors the progress of the reaction. After the reaction, the resin was washed 6 times with DMF. Then repeat the above operation, and sequentially react with Fmoc-Pro-OH, Fmoc-Lys(Boc, iPr)-OH, Fmoc-Leu-OH to prepare H-Leu-Lys(Boc, iPr)-Pro-D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com