Transparent oxygen-blocking water-blocking film and preparation method thereof

A thin-film, oxygen-barrier technology, applied in the coating and other directions, can solve the problems of plasticization, oxygen-barrier and water-barrier performance, and air-tightness deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The present invention also provides a method for preparing the above-mentioned transparent oxygen- and water-blocking film, comprising the following steps:

[0035] mixing hydrotalcite nanosheets with Tween 80 aqueous solution, stirring at room temperature for 2 to 5 hours, and performing hydrophobic modification to obtain hydrophobically modified hydrotalcite nanosheets;

[0036] Dispersing the hydrophobically modified hydrotalcite nanosheets in water to obtain a hydrophobically modified hydrotalcite nanosheet dispersion;

[0037] The hydrophobically modified hydrotalcite nanosheet dispersion and the hydrophobic polymer aqueous dispersion are alternately spin-coated on the surface of the film substrate to obtain a transparent oxygen- and water-blocking film.

[0038] In the invention, the hydrotalcite nanosheets are first mixed with the Tween 80 aqueous solution, stirred at room temperature for 2-5 hours, separated, washed and dried to obtain the hydrophobically modifi...

Embodiment 1

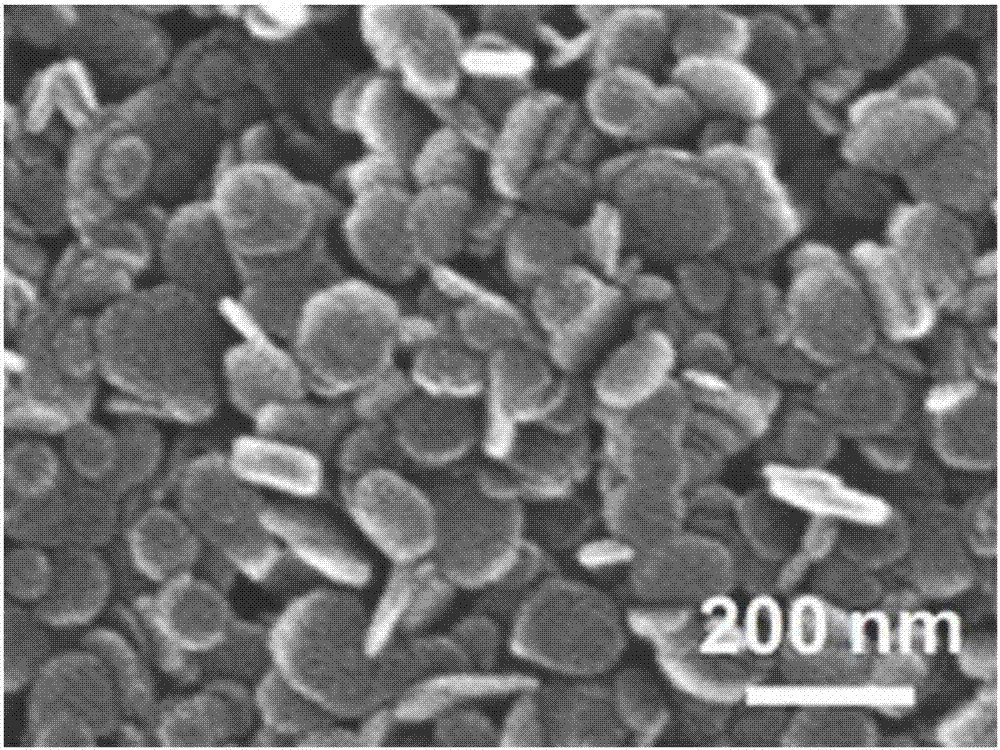

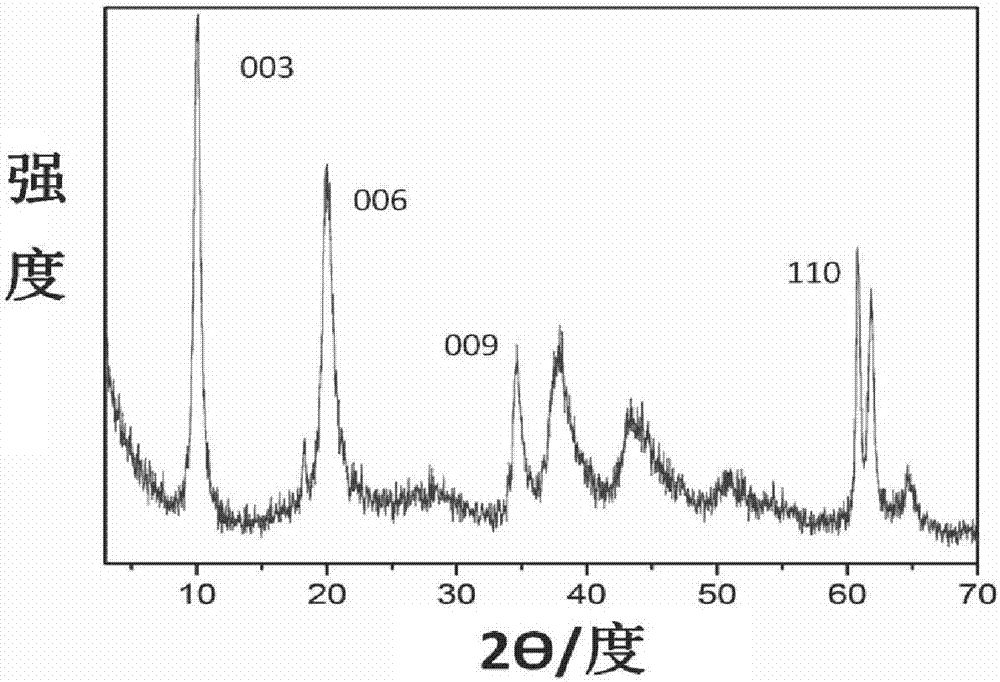

[0071] 1. Mix 5.1282g Mg(NO 3 ) 2 ·6H 2 O, 3.7513gAl(NO 3 ) 3 9H 2 O was dissolved in 50mL deionized water to obtain a mixed metal salt solution; 4g urea was dissolved in 50mL deionized water to obtain a urea solution; the metal salt solution was mixed with the urea solution, stirred evenly, and placed in an oven at 110°C. Crystallize for 24 hours, then naturally cool the reaction system to room temperature, and centrifuge to obtain a solid; wash the solid with deionized water until the deionized water after washing is neutral, and obtain hydrotalcite nanosheets;

[0072] 2. Disperse the hydrotalcite nanosheets in an aqueous solution of Tween 80 with a concentration of 0.25wt.% according to the mass ratio of the hydrotalcite nanosheets to Tween 80 of 35:1, stir at room temperature for 4 hours, and then separate, Washing and drying to obtain hydrophobically modified hydrotalcite nanosheets;

[0073] 3. Prepare the aqueous dispersion of hydrophobically modified hydrotalcit...

Embodiment 2

[0085] 1. Mix 5.1282g Mg(NO 3 ) 2 ·6H 2 O, 3.7513gAl(NO 3 ) 3 9H 2 O was dissolved in 50mL deionized water to obtain a mixed metal salt solution; 4g urea was dissolved in 50mL deionized water to obtain a urea solution; the metal salt solution was mixed with the urea solution, stirred evenly, and placed in an oven at 100°C. Crystallize for 26 hours, then naturally cool the reaction system to room temperature, and centrifuge to obtain a solid; wash the solid with deionized water until the deionized water after washing is neutral, and obtain hydrotalcite nanosheets;

[0086] 2. According to the mass ratio of hydrotalcite nanosheets to Tween 80 of 30:1, the hydrotalcite nanosheets were dispersed in an aqueous solution of Tween 80 with a concentration of 0.25wt.%, stirred at room temperature for 4 hours, and then separated , washing, and drying to obtain hydrophobically modified hydrotalcite nanosheets;

[0087] 3. Prepare a hydrophobically modified hydrotalcite nanosheet aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com